Ultrasonic phased array weld joint detection magnetic adsorption wall-climbing robot and working method thereof

A wall-climbing robot and ultrasonic phased array technology, applied in the field of robotics, can solve the problems of reducing manual labor, poor working environment, and low detection efficiency, and achieve automation and intelligence, reduce risks, and have strong obstacle-crossing capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

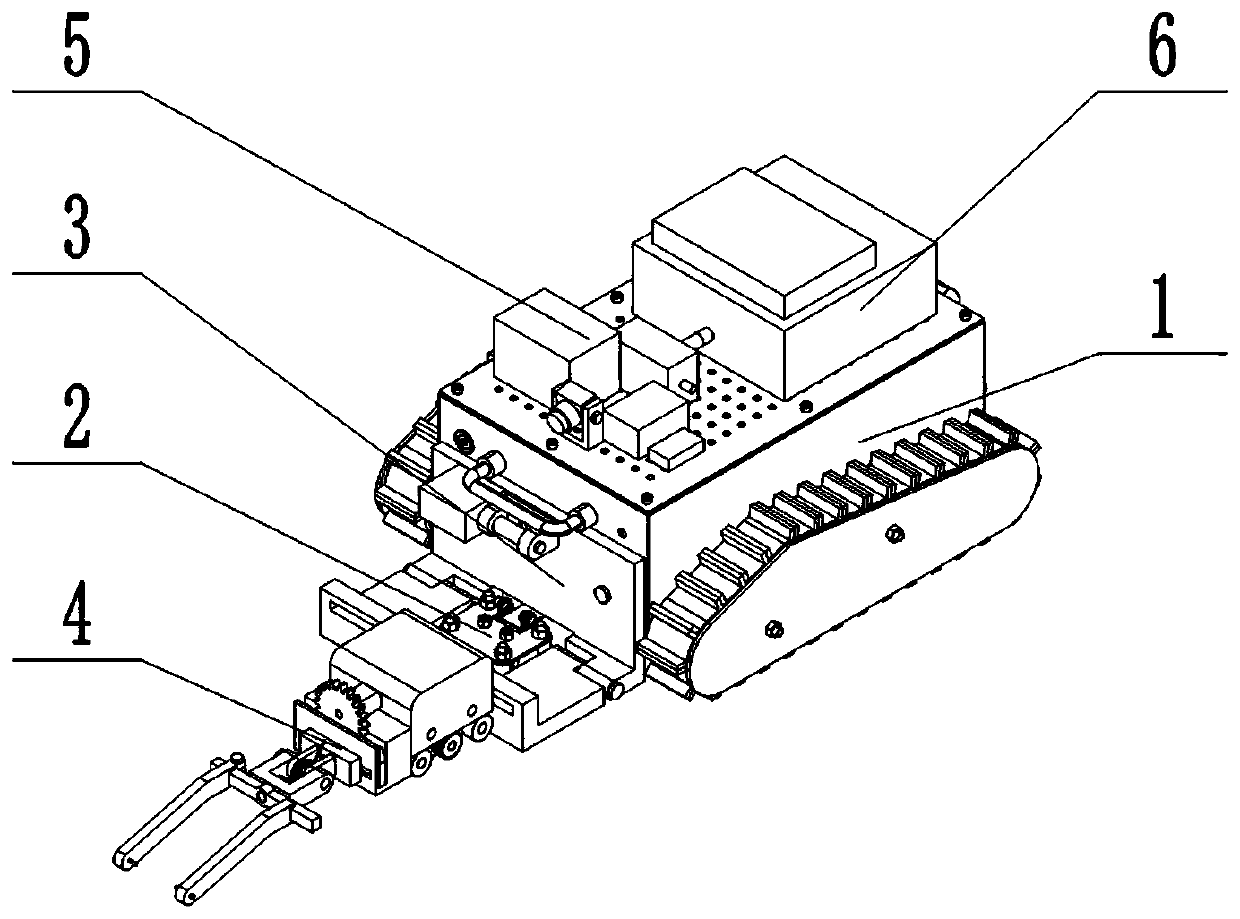

[0038] An ultrasonic phased array weld detection magnetic adsorption wall-climbing robot, including a mobile chassis device 1, an anti-overturning device 2, a lifting component 3, a scanning frame device 4, a control and detection system 5, and a coupling agent device 6,

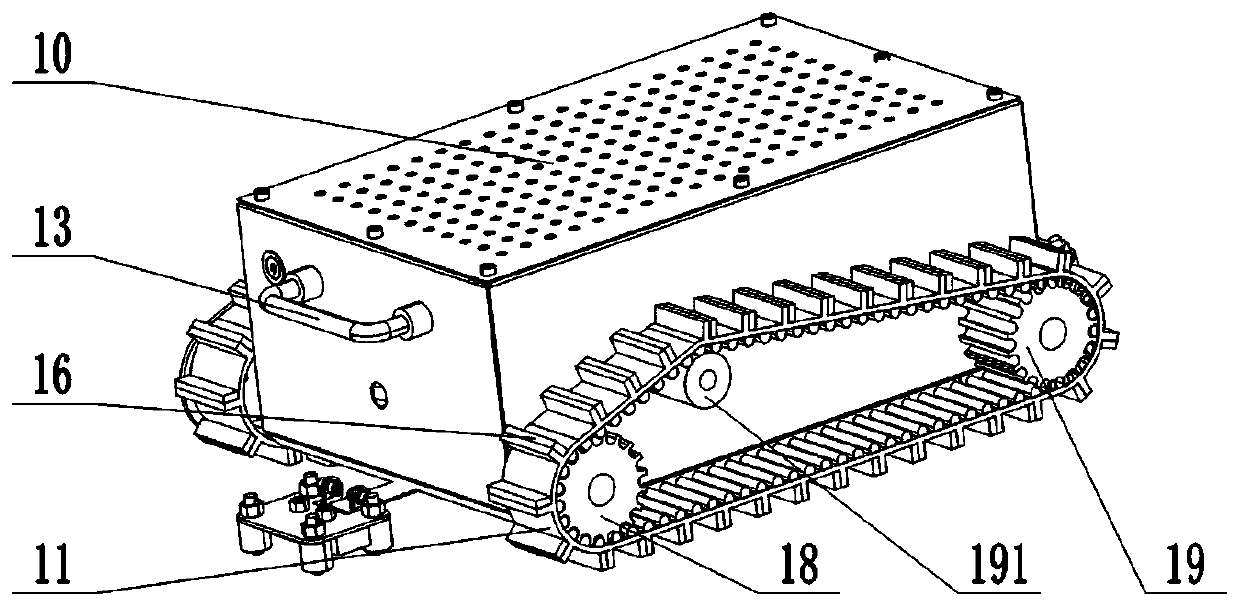

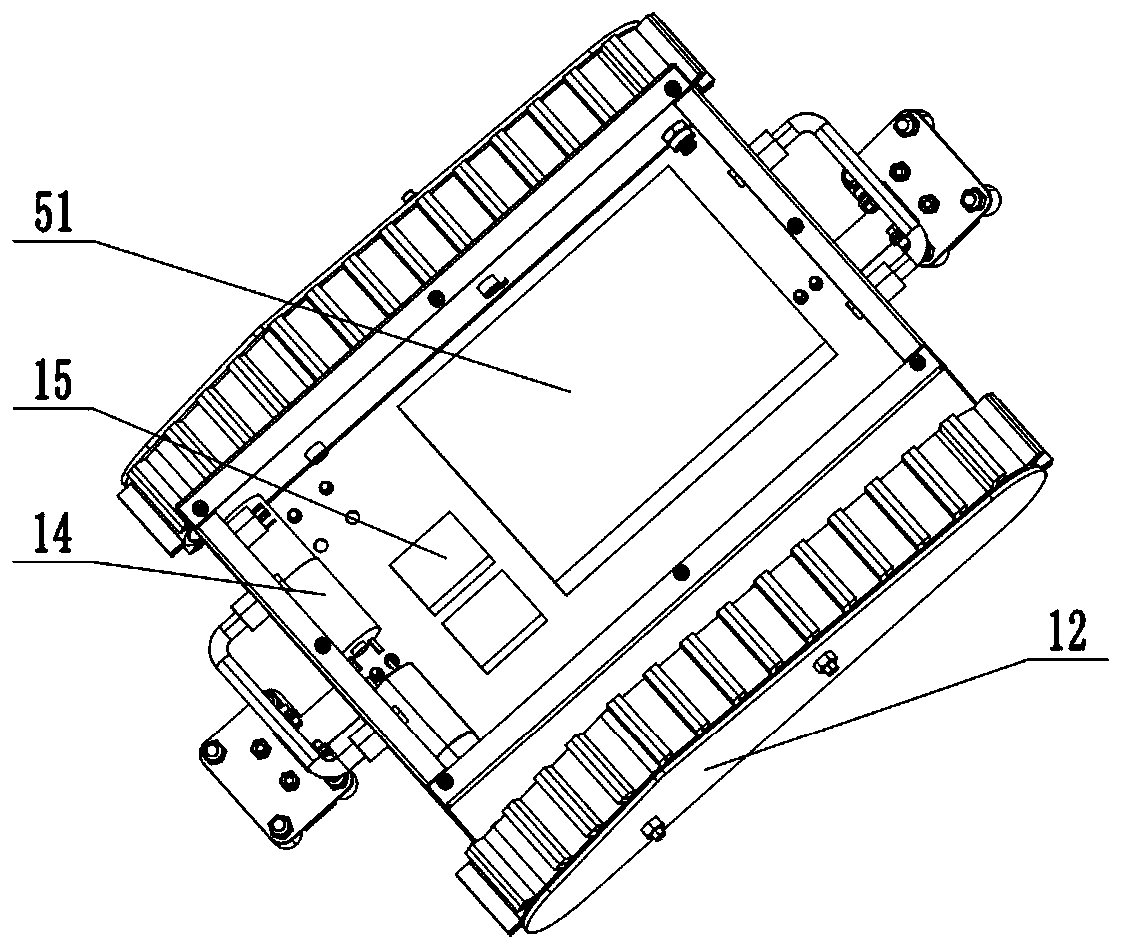

[0039] Mobile chassis device 1 comprises housing 10, rubber track 11, DC geared motor 14, DC motor driver 15, track permanent magnet 16, driving wheel 18, driven wheel 19 and auxiliary wheel 191, and DC geared motor 14 is set in housing 10 and DC motor driver 15, DC motor driver 15 controls the operation of DC geared motor 10, drive wheel 18, driven wheel 19 and auxiliary wheel 191 are respectively installed on the left and right sides of housing 10, the output of drive wheel 18 and DC geared motor 14 The shafts are connected to provide power for the housing 10, the driving wheel 18, the driven wheel 19 and the auxiliary wheel 191 are connected through the rubber track 11, the driven wheel 19 and the auxiliar...

Embodiment 2

[0043] On the basis of Embodiment 1, the lifting assembly 3 includes an auxiliary plate 31, a bracket 32, a reel 33, a support plate 34 and a stepping motor 37 for lifting, and the support plate 34 is fixedly connected to the outer wall of the head end of the housing 10. The stepper motor 37 for lifting is installed on the plate 34, and the stepper motor 37 for lifting links to each other with the stepper motor driver 54, and the output shaft of the stepper motor 37 for lifting links to each other with the reel 33, and the reel 33 is installed in the middle of the support 32, Rope is provided on reel 33, and auxiliary plate 31 links to each other with the bottom end of support plate 34 by pin 35, and suspension ring 36 is provided with in the movable end middle part of auxiliary board 31, and suspension ring 36 links to each other with rope, and the stepper motor 37 of lifting can According to the command sent by the main controller 52 to the stepper motor driver 54, it control...

Embodiment 3

[0045] On the basis of Embodiment 2, the anti-overturning device 2 includes a magnetic yoke plate 21, a magnetic steel block 22 and an connecting plate 23, the magnetic yoke plate 21 is connected to the bottom of the head and tail ends of the housing 10 through the connecting plate 23, and the magnetic steel block 22 It is fixed on the bottom of the yoke plate 21.

[0046] The anti-overturning device 2 also includes balls 24 uniformly installed on the four corners of the yoke plate 21 .

[0047] The couplant device 6 includes a couplant storage tank 61 and a circulation pump 62, the couplant storage tank 61 and the circulation pump 62 are fixed on the top of the casing 10, the flaw detection data collector 53 is installed on the couplant storage tank 61, and the circulation pump 62 and the The couplant storage tank 61 is connected, and the circulation pump 62 pumps the couplant into the contact surface between the ultrasonic probe and the adsorbent through a hose, so as to enh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com