Flexible manufacturing system deadlock-free scheduling method based on improved genetic algorithm

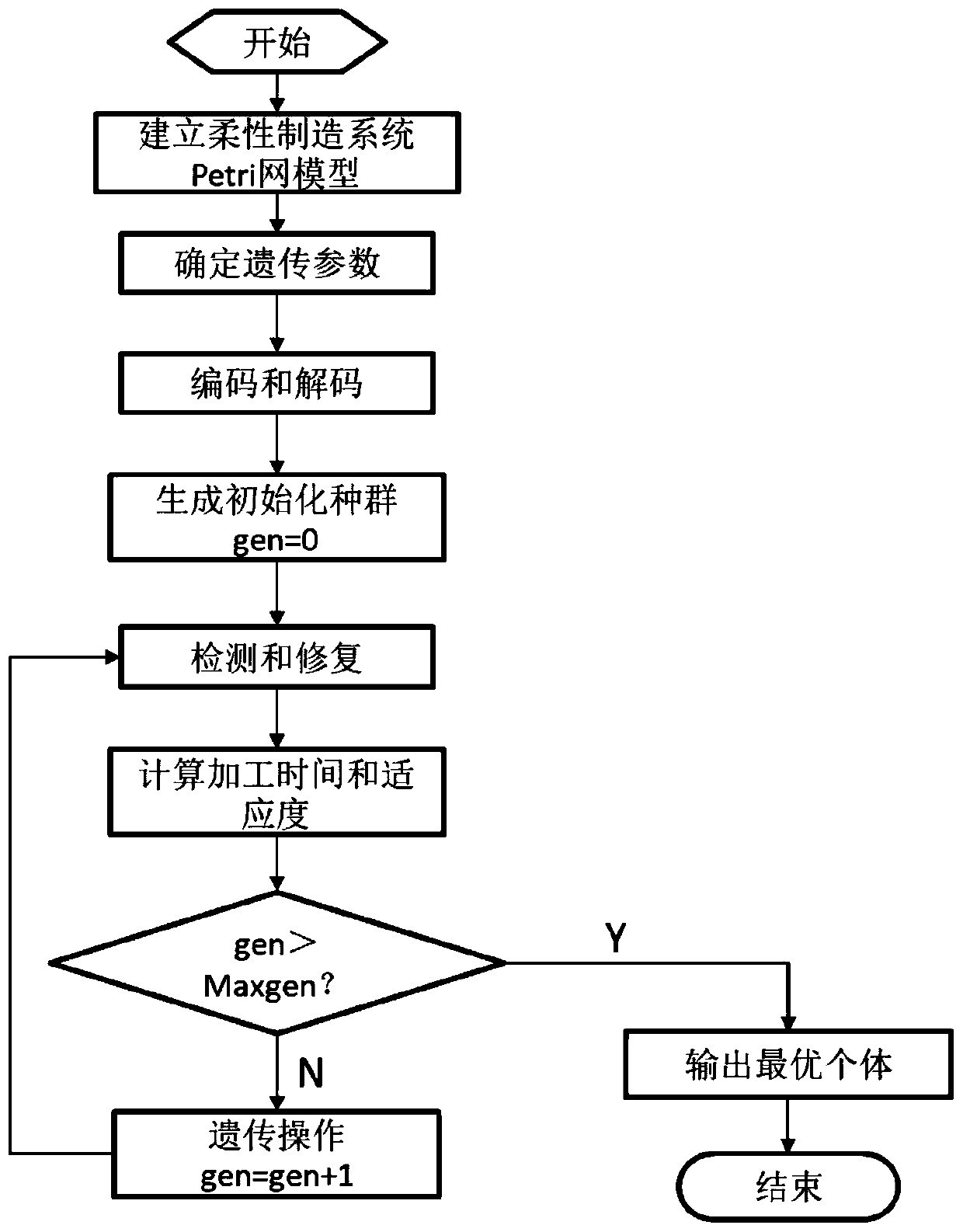

A flexible manufacturing system, a technology for improving genetic algorithms, applied in manufacturing computing systems, genetic laws, calculations, etc., can solve problems such as low efficiency, inability to repair infeasible coding sequences, and inability to jump out of local optimal values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

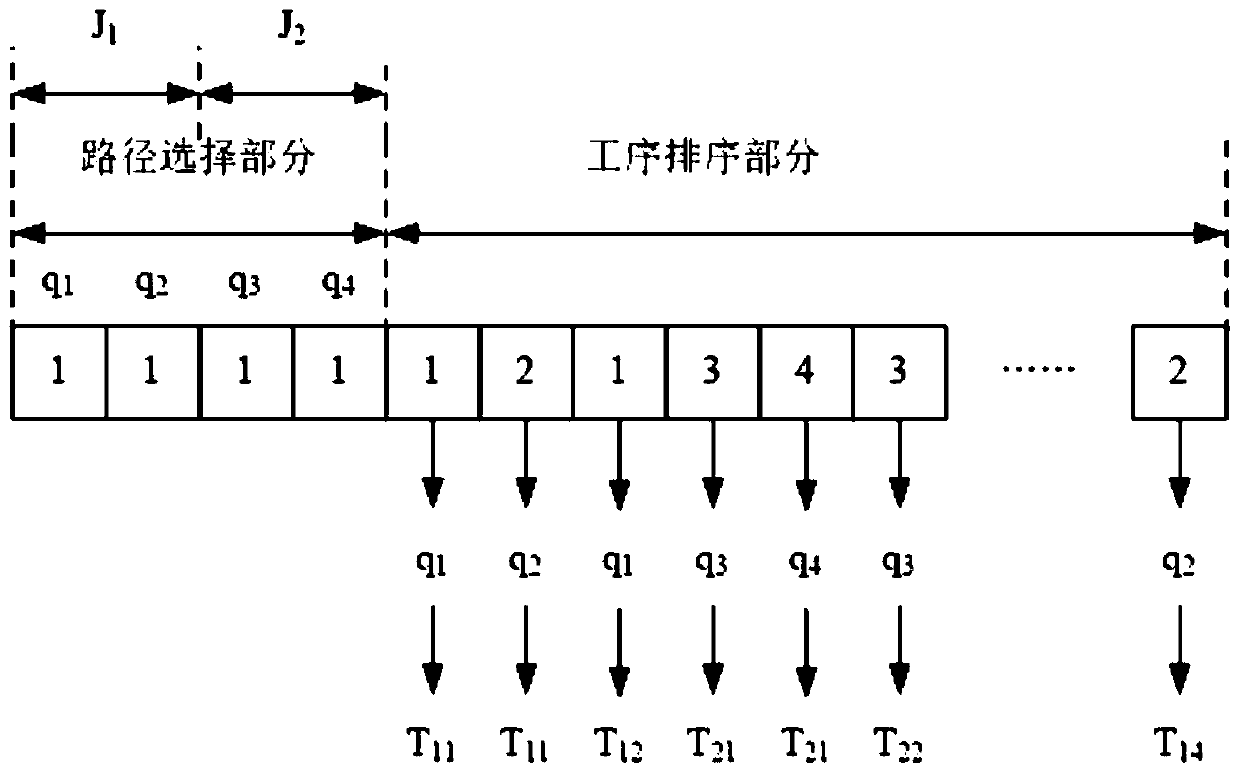

[0043] This embodiment is the application of the deadlock-free scheduling method of the flexible manufacturing system based on the improved genetic algorithm in the tool cutting production unit. The tool cutting production unit uses cutting machine tools, handling robots and grinding machine tools to produce two types of tools; different tool processing sequence codes correspond to different maximum completion times, and the optimization goal of its scheduling strategy is based on the improved genetic algorithm. The specific steps for fast optimization of the maximum completion time are as follows:

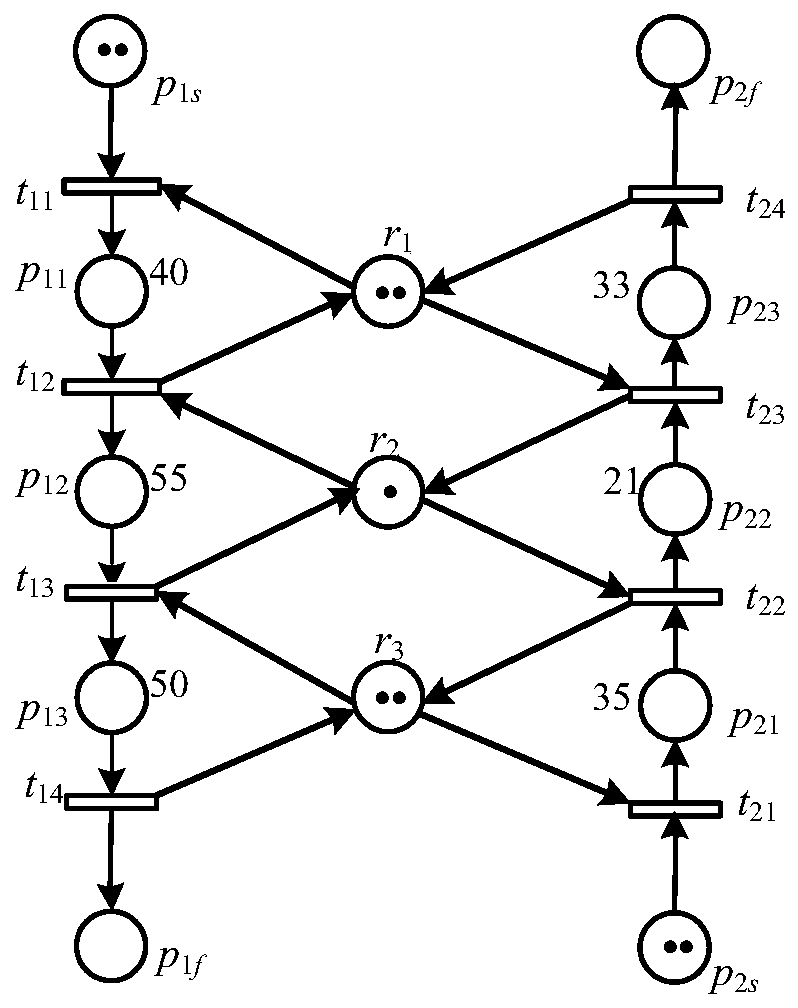

[0044] Step 1: Establish the Petri net model of the tool cutting production unit: the tool cutting production unit manufacturing system consists of three kinds of machines——cutting machine tool, handling robot and grinding machine tool (respectively use r 1 、r 2 、r 3 Indicates) composition; the system can process two types of knives, the operation sequence of the first type of k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com