High-power narrow-linewidth optical fiber laser polarization control system and method

A technology of polarization control and fiber laser, applied in the direction of lasers, laser components, phonon exciters, etc., can solve problems such as unstable modes, damage to fiber end faces, complex cutting and welding processes, etc., and achieve high control accuracy and small control residues. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

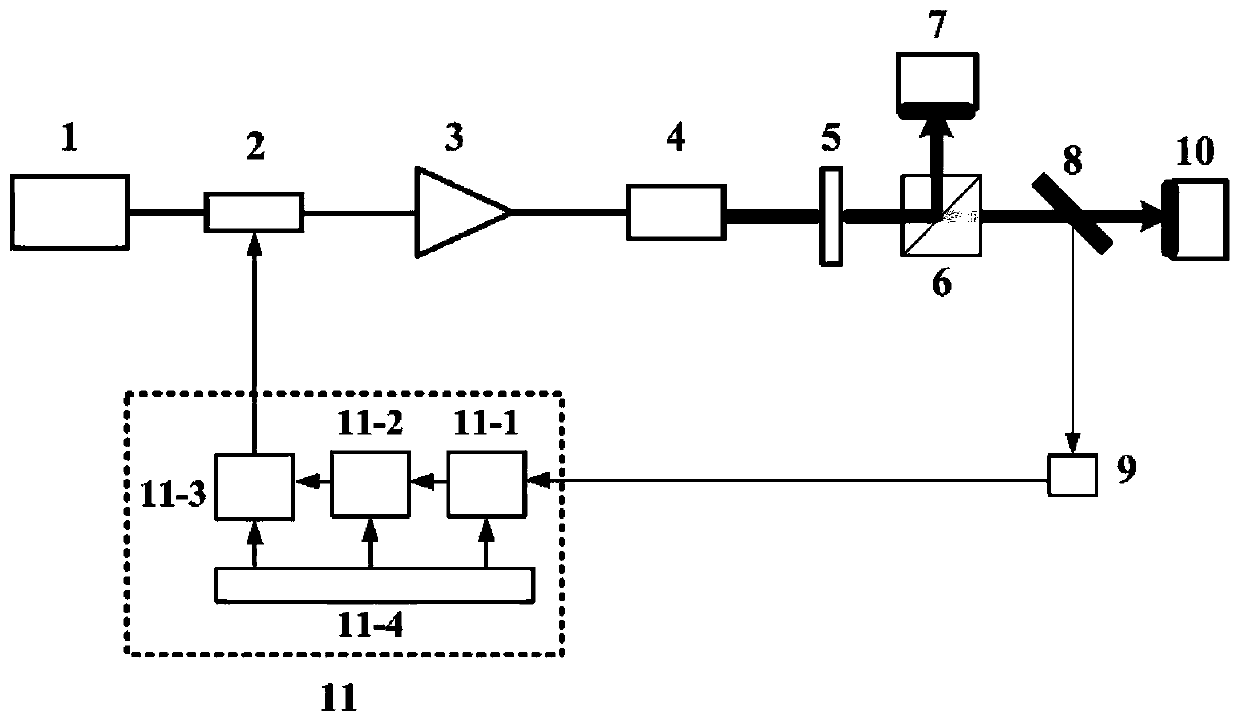

[0042] as attached figure 1 As shown, this embodiment provides a high-power narrow-linewidth fiber laser polarization control system, including a low-power narrow-linewidth linearly polarized fiber laser 1, a polarization controller 2, a cascaded non-polarization-maintaining fiber amplifier system 3, and a collimator 4. Half wave plate 5, polarization beam splitter 6, 1# power meter 7, optical beam splitter 8, photodetector 9, 2# power meter 10, active polarization control system 11. Among them, the active polarization control system 11 is composed of a data acquisition module 11-1, a data processing module 11-2, a data output module 11-3, and a hardware start-stop module 11-4.

[0043] The fiber laser output from the low-power narrow-linewidth linearly polarized fiber laser 1 is first incident on the polarization controller 2; the laser after passing through the polarization controller 2 is injected into the cascaded non-polarization-maintaining fiber amplifier system 3 for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com