Parameter design method of phase-shifted full-bridge converter based on ZVS load range

A technology of phase-shifting full bridge and parameter design, applied in design optimization/simulation, output power conversion device, conversion of DC power input to DC power output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

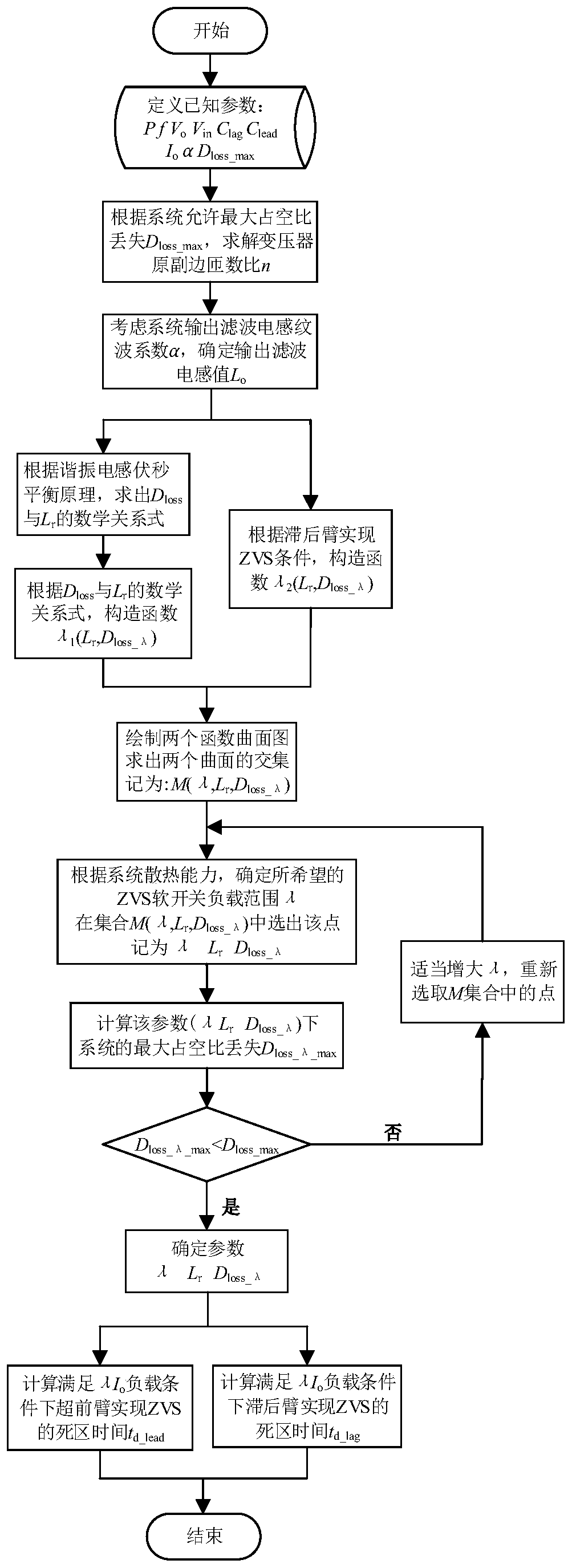

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

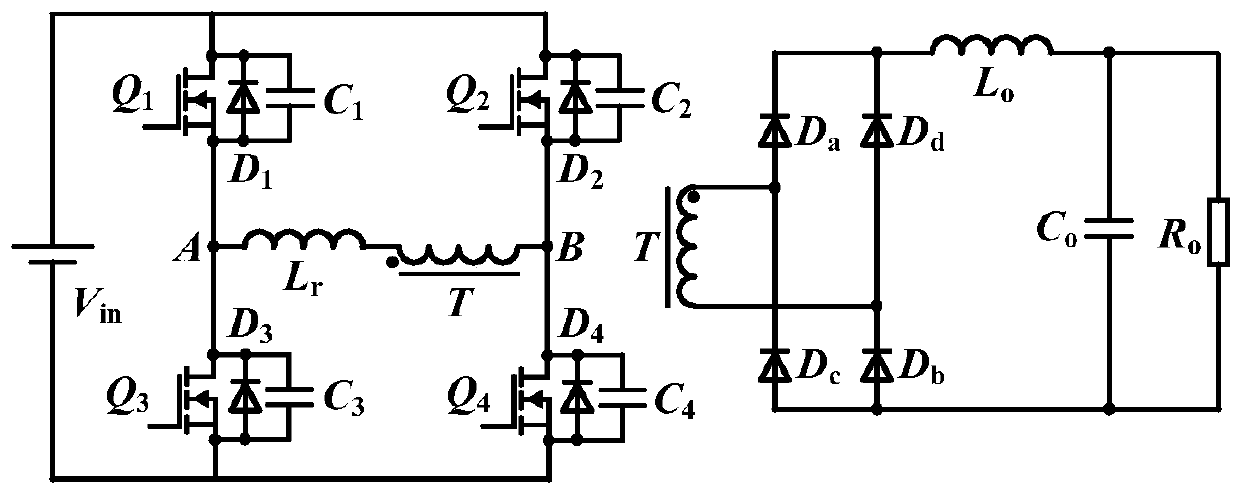

[0037] refer to figure 1 Shown is the basic topology of the main circuit of the ZVS phase-shifted full-bridge DC-DC converter, where Q1 and Q3 are leading transistors, Q2 and Q4 are lagging transistors, D1~D4 are switching body diodes, and C1~C4 are switching diodes. Tube parallel resonant capacitor, Lr is resonant inductance (including leakage inductance of high frequency transformer), T is high frequency transformer, Da, Db, Dc, Dd are secondary side rectifier diodes, L 0 is the output filter inductor, C 0 is the output filter capacitor, R 0 for the load. The leading arms Q1 and Q3 are respectively ahead of the lagging arms Q2 and Q4 by a phase shift angle, and the output voltage is adjusted by changing the magnitude of the phase shift angle. Assuming that the inductors, power transformers, power switches, diodes and other components in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com