Synthetic runway surface layer disinfectant, preparation method thereof and synthetic runway surface layer disinfection method

A disinfectant and surface layer technology, applied in the direction of disinfectant, botany equipment and method, biocide, etc., can solve the problems of excessive harmful substances in the plastic runway, endangering the health of young people, etc., and achieve the improvement of chelation ability, elimination of injuries, and chelation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

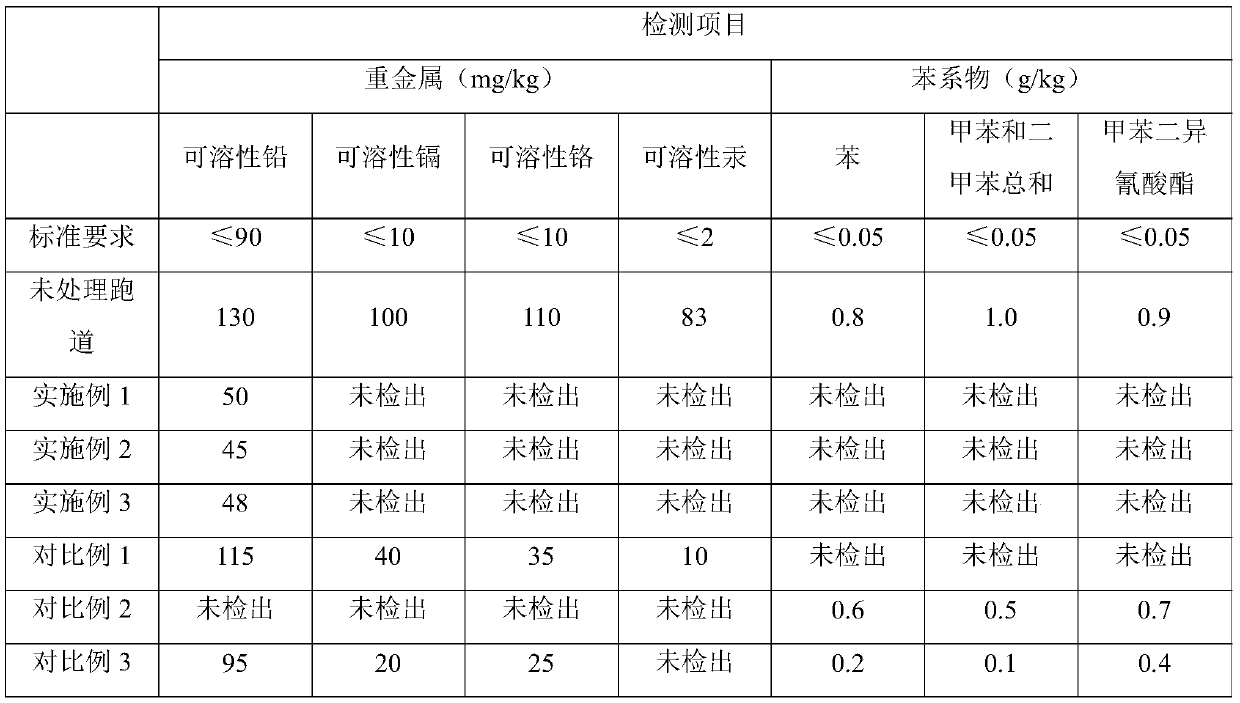

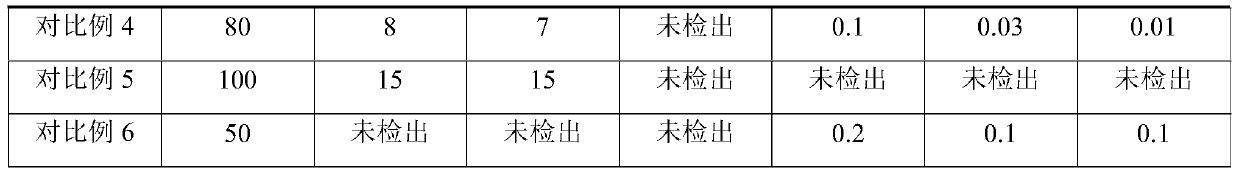

Examples

Embodiment 1

[0029] A kind of synthetic runway surface layer disinfectant, comprises the component of following mass percentage:

[0030] 10% of heavy metal chelating agent, 10% of benzene series trapping agent, 30% of hydrogen peroxide, 1% of lauryl alcohol, and the balance is water; the heavy metal chelating agent is made of nano-alumina and polycarboxylic acid mixed in a mass ratio of 3:1 , The benzene series scavenger is made of sodium silicate and starch mixed in a mass ratio of 2:1.

[0031] Synthetic runway surface layer disinfectant in the present example embodiment is made through the following steps:

[0032] S1: Heat the water to about 50°C, then add the benzene series capture agent, stir until completely dissolved, and obtain the initial solution;

[0033] S2: After the temperature of the initial solution drops to room temperature, add a heavy metal chelating agent and stir evenly to obtain a base solution;

[0034] S3: 5 minutes before disinfecting the synthetic runway surfa...

Embodiment 2

[0036] A kind of synthetic runway surface layer disinfectant, comprises the component of following mass percentage:

[0037] 8% of heavy metal chelating agent, 12% of benzene series trapping agent, 20% of hydrogen peroxide, 1.5% of lauryl alcohol, and the balance is water; wherein the heavy metal chelating agent is made of nano-alumina and polycarboxylic acid mixed in a mass ratio of 2:1 , The benzene series scavenger is made of sodium silicate and starch mixed in a mass ratio of 4:1.

[0038] Synthetic runway surface layer disinfectant in the present example embodiment is made through the following steps:

[0039] S1: Heat the water to about 45°C, then add the benzene series capture agent, stir until completely dissolved, and obtain the initial solution;

[0040] S2: After the temperature of the initial solution drops to room temperature, add a heavy metal chelating agent and stir evenly to obtain a base solution;

[0041] S3: 5 minutes before disinfecting the synthetic run...

Embodiment 3

[0043] A kind of synthetic runway surface layer disinfectant, comprises the component of following mass percentage:

[0044] 13% of heavy metal chelating agent, 7% of benzene series trapping agent, 50% of hydrogen peroxide, 0.5% of menthol, and the balance is water; wherein the heavy metal chelating agent is made of nano-alumina and polycarboxylic acid mixed in a mass ratio of 6:1 , The benzene series scavenger is made of sodium silicate and starch mixed in a mass ratio of 1:1.

[0045] Synthetic runway surface layer disinfectant in the present example embodiment is made through the following steps:

[0046] S1: Heat the water to about 55°C, then add the benzene series capture agent, stir until completely dissolved, and obtain the initial solution;

[0047] S2: After the temperature of the initial solution drops to room temperature, add a heavy metal chelating agent and stir evenly to obtain a base solution;

[0048] S3: 10 minutes before disinfecting the synthetic runway su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com