Uniform mixing equipment for epoxy powder coating processing

A technology of epoxy powder and mixing equipment, which is applied to epoxy resin coatings, coatings, mixers, etc., can solve problems such as difficult cleaning, low utilization rate of raw materials, and easy adhesion to the inner wall of the reactor, and achieves improved Fully and enhance the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

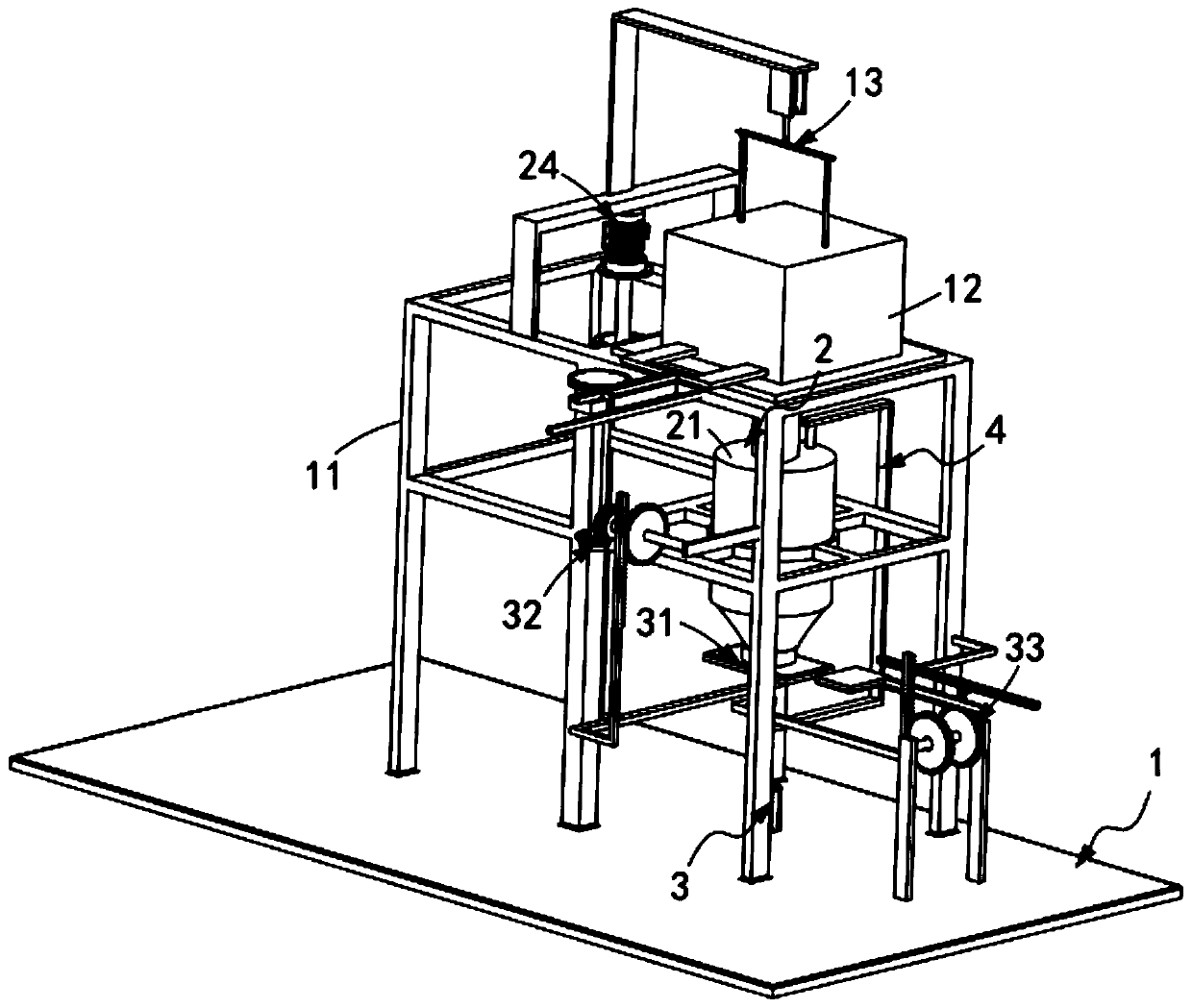

[0065] like figure 1 , figure 2 Shown, a kind of homogeneous mixing equipment for epoxy powder coating processing, comprising:

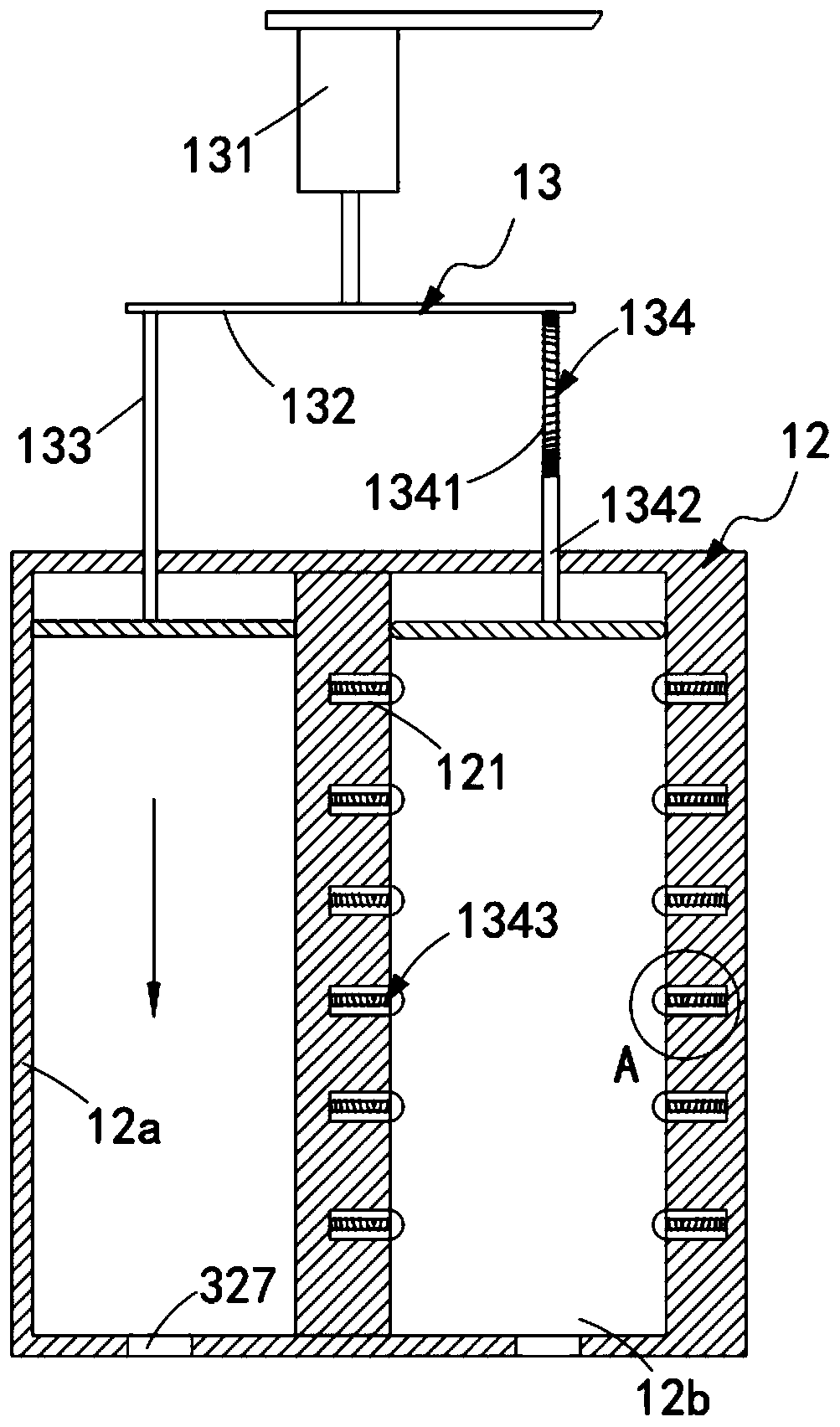

[0066] The raw material transmission mechanism 1, the raw material transmission mechanism 1 comprises a frame 11, a storage bin 12 installed on the frame 11 and a pushing assembly 13 arranged above the storage bin 12, the storage bin 12 includes a Material storage space 12a and B material storage space 2b;

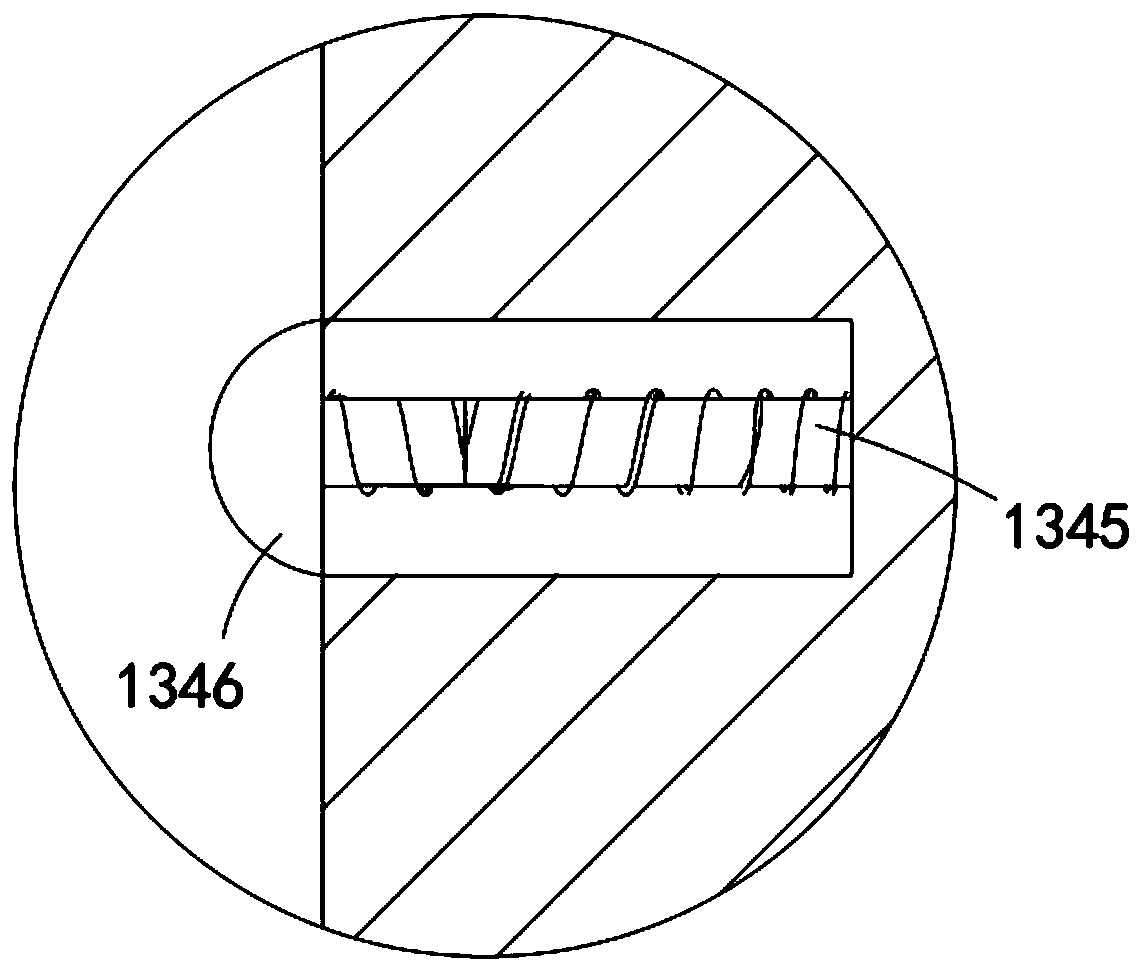

[0067] A uniform mixing mechanism 2, which includes a reaction kettle 21 installed on the frame 11, a spreading assembly 22 located in the reaction kettle 21 and communicated with the material A storage space 12a , the thinning assembly 23 built in the spreading assembly 22 and communicated with the B material storage space 2b, and the thinning assembly 23 installed on the frame 11 and used to drive the spreading assembly 22 and the thinning assembly 23 synchronously rotating drive assembly 24;

[0068] The mixing output mechanism 3, the mix...

Embodiment 2

[0116] like Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0117] further, such as Figure 10 As shown, the scraping mechanism 4 includes a connecting rod 41 connected to the support rod 312 and a scraping ring 42 fixedly connected to the connecting rod 41 and slidably arranged in the reactor 21. The inner wall of the reaction kettle 21 is matched and attached.

[0118] In this embodiment, by setting the scraping mechanism 4, on the one hand, the inner wall of the reaction kettle is cleaned in time, while the inner wall is cleaned in real time, the raw materials are fully utilized, and the mixed material is scraped off so that it falls on the blocking plate 336, and the bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com