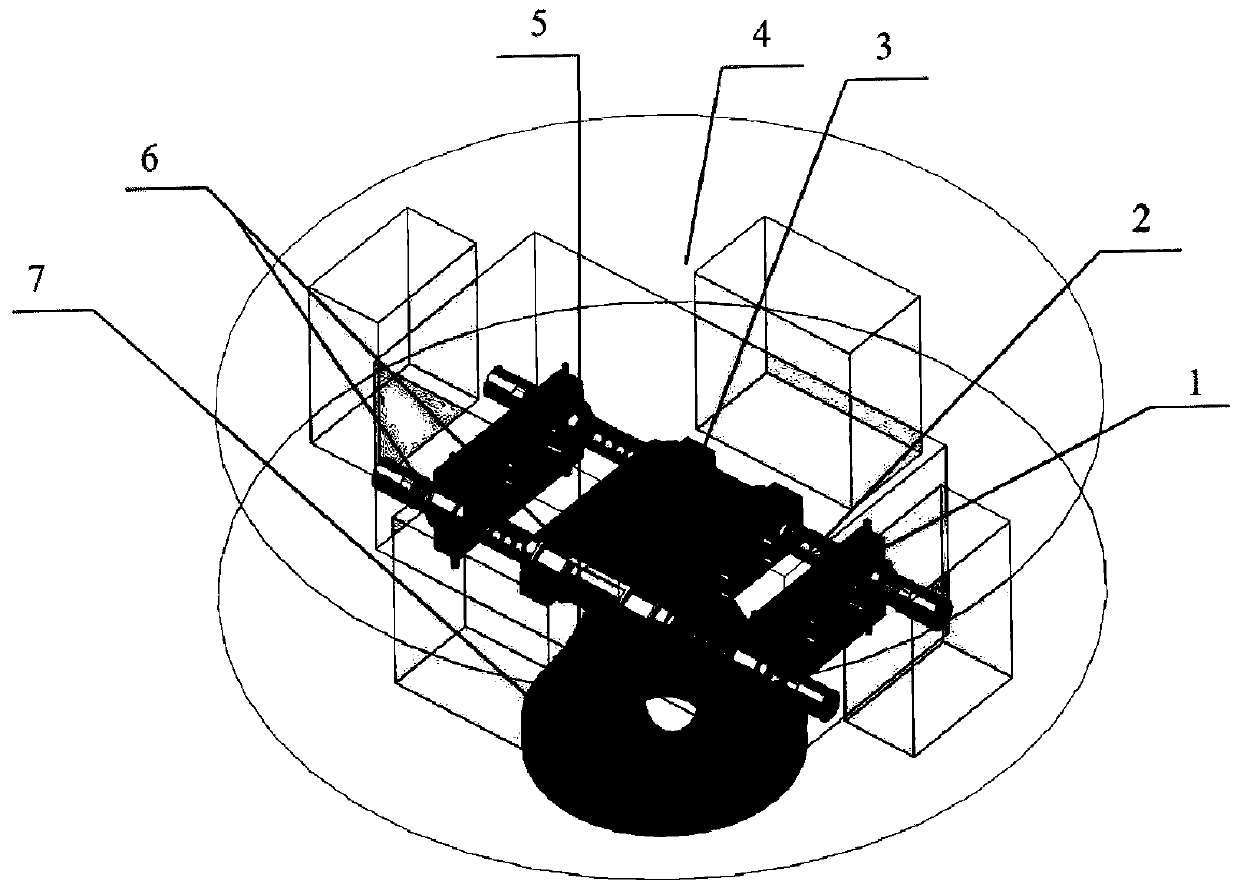

Variable-mass power centrifuge and experimental method

A centrifuge and variable quality technology, applied in the direction of centrifuges, measuring devices, vibration testing, etc., can solve the problems of low-frequency driving difficulties, complex structures, high driving voltage, etc., and achieve simple and reliable connection methods, simple implementation methods, and compact device structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

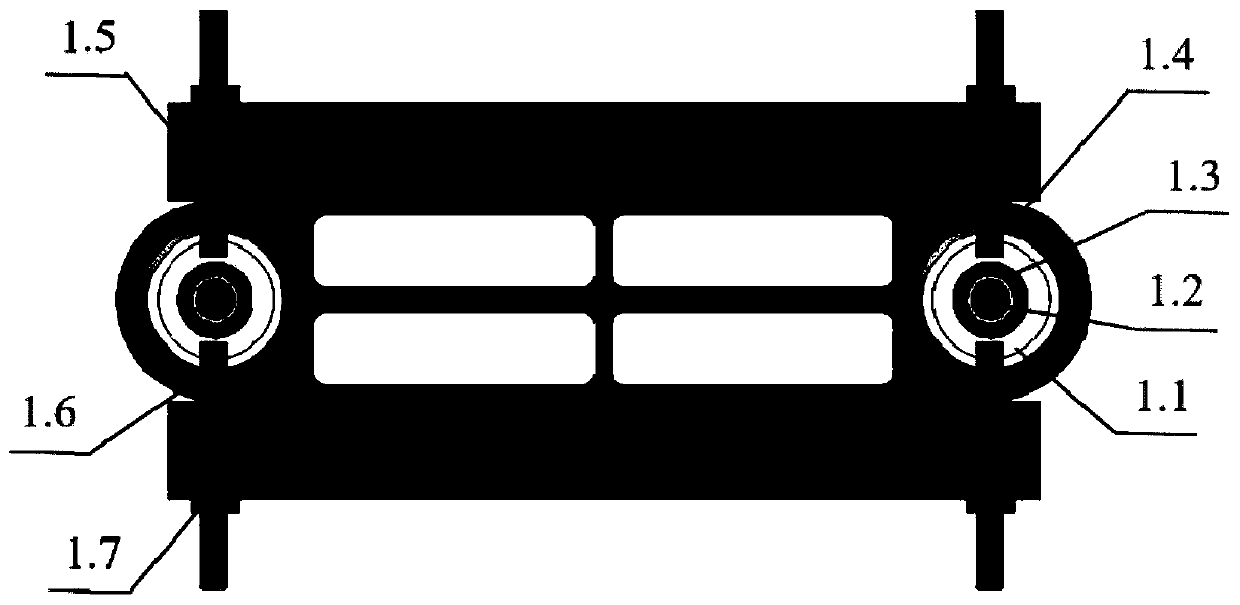

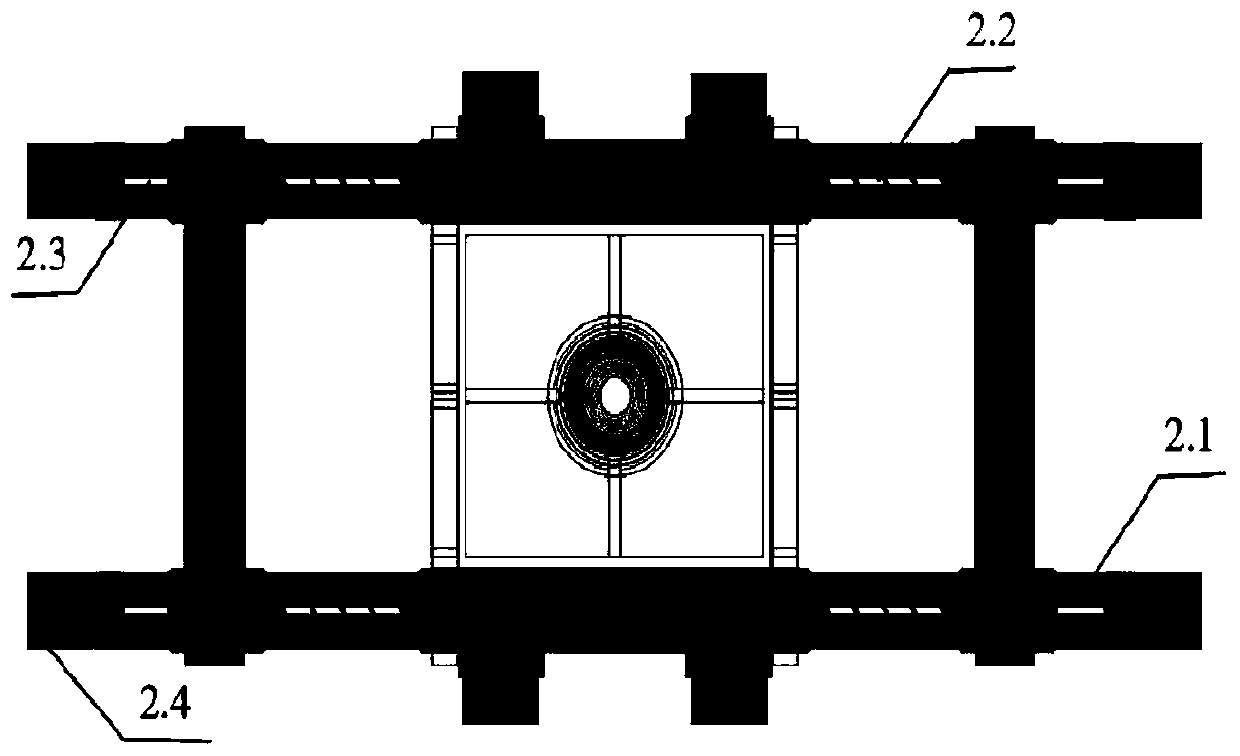

[0067] Realization of shock loads in a centrifugal vibration environment:

[0068] The additional quality block 1.5 is enough, when the relatively large DC voltage is transmitted to the power supply device 3.3 through the circuit transmission system 5.1, and is transmitted to the electromagnetic coil 3.2 by the power supply device 3.3 through four branch circuits 3.4, at this time, a relatively high voltage is induced on the electromagnet core 3.1. Large electromagnetic force, the force interacts with the permanent magnet 1.2, and the moment of inertia of the system changes transiently. According to the conservation of momentum moment, the corresponding rotational angular acceleration and angular velocity also change accordingly; the two sliding masses move toward ( or away from) the electromagnetic device moves in 3 directions, at this time, a transient acceleration will be generated to act on the test piece to realize transient impact load loading.

[0069] Realization of al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com