Wet-mixed mortar additive and preparation method thereof

A wet-mixed mortar and additive technology, applied in the field of wet-mixed mortar, can solve the problems of difficulty in ensuring the opening time and workability of the mortar, large mixing time error, etc., achieve good water retention effect, prolong the hydration time, and improve the density of the mortar. The effect of final compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

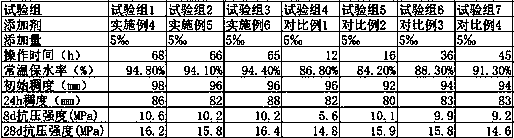

Examples

Embodiment 1

[0022] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0023] Example 1

[0024] A wet-mix mortar additive, including the following raw materials according to weight percentage: 1.5% sodium α-olefin sulfonate, 3% lauryl sulfuric acid, 5% polycarboxylate water reducer, 10% sodium gluconate, and 2% diethanolamine %, sodium sulfate 3%, 4-methyl-2-pentenoic acid 3%, modified nano silicon dioxide 10% and the balance of water. The modified nano-silica is nano-silica doped with glass powder and titanium dioxide composite.

Embodiment 2

[0026] A wet-mix mortar additive, including the following raw materials according to weight percentage: 0.5% sodium α-olefin sulfonate, 5% lauryl sulfuric acid, 3% polycarboxylate water reducer, 15% sodium gluconate, 3% diethanolamine %, 2% sodium sulfate, 5% 4-methyl-2-pentenoic acid, 5% modified nano silicon dioxide and the rest of water. The modified nano-silica is nano-silica doped with glass powder and titanium dioxide composite. The modified nano-silica is nano-silica doped with glass powder and titanium dioxide composite.

Embodiment 3

[0028] A wet-mix mortar additive, including the following raw materials according to weight percentage: 1.5% sodium α-olefin sulfonate, 2% lauryl sulfuric acid, 8% polycarboxylate water reducer, 10% sodium gluconate, 1 diethanolamine %, sodium sulfate 5%, 4-methyl-2-pentenoic acid 2%, modified nano silicon dioxide 10% and the balance of water. The modified nano-silica is nano-silica doped with glass powder and titanium dioxide composite. The modified nano-silica is nano-silica doped with glass powder and titanium dioxide composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com