Temporary plugging agent with tassel-shaped two ends as well as preparation method and application thereof

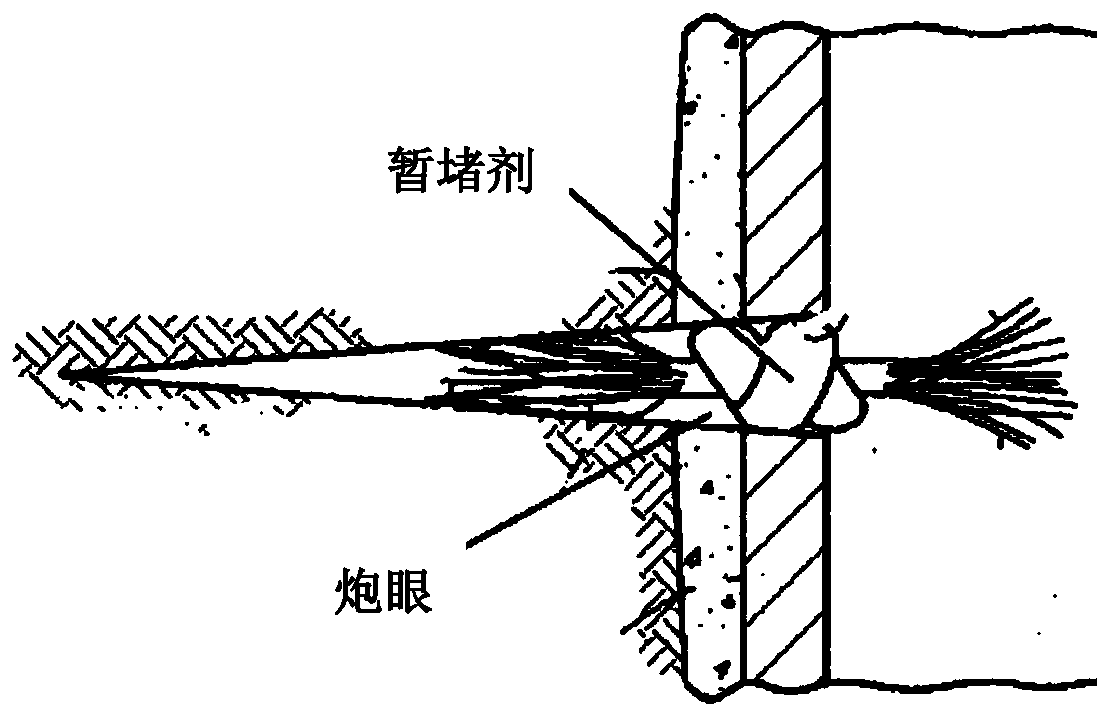

A temporary plugging agent, tassel technology, applied in chemical instruments and methods, mining fluids, earthwork drilling and other directions, can solve the problems of unfavorable suspension and dispersion of tassel, unfavorable temporary plugging agent salvage or flowback, mutual entanglement, etc., and achieve degradation. Controllable time, good blocking effect, and effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

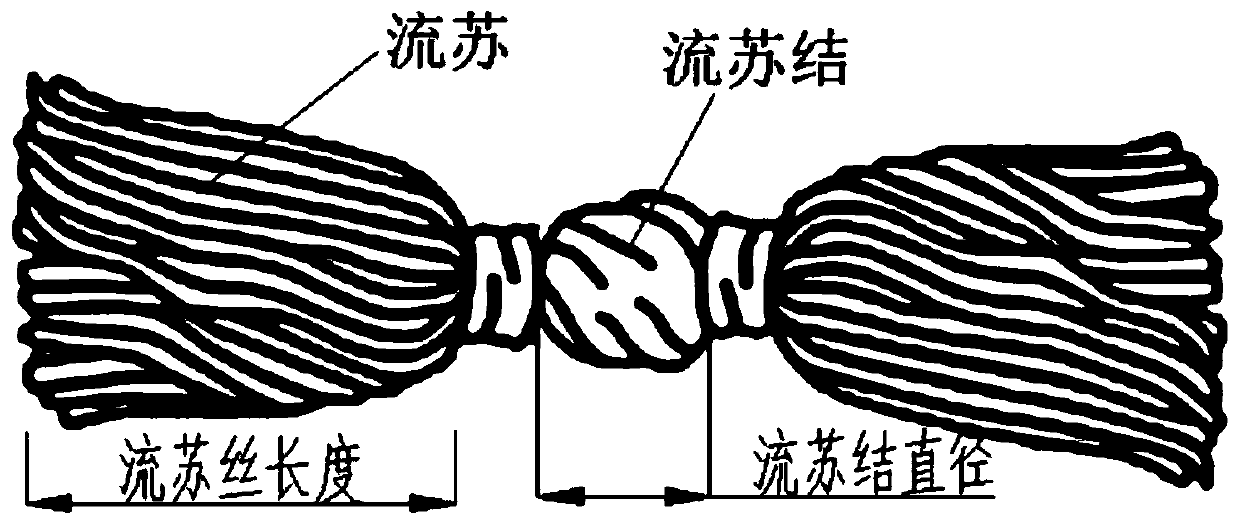

[0044] One aspect of the embodiments of the present invention provides a method for preparing a tassel-shaped temporary plugging agent at both ends, which includes:

[0045] The water-swellable deformed fiber and the high-strength rigid fiber are paralleled and compounded to form a temporary plugging fiber bundle;

[0046] Knotting the temporary plugging fiber bundle to form a temporary plugging fiber bundle with a tassel knot main body in the middle and tassel-like ends at both ends; and,

[0047] The temporary plugging fiber bundle with tassel-like ends is impregnated with polyester resin to obtain a tassel-like temporary plugging agent.

[0048] In some preferred embodiments, the preparation method includes: compounding the water-swellable deformed fiber and the high-strength rigid fiber by twisted or non-twisted paralleled fibers to form the temporary plugging fiber bundle.

[0049] In some more specific embodiments, the preparation method of the tassel-like temporary blo...

Embodiment 1

[0089] A preparation method of a tassel-shaped temporary plugging agent applied to both ends of temporary plugging fracturing is as follows:

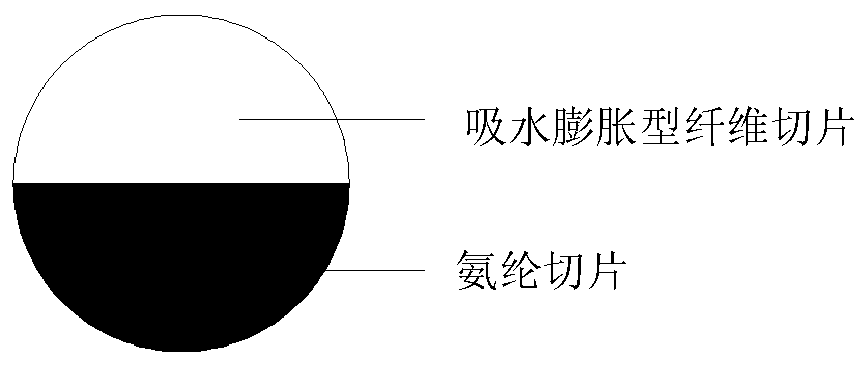

[0090] (1) Preparation of water-swellable deformed fiber: Slice the water-swellable fiber (the mass of adipate monomer unit accounts for 0% of the mass of polyterephthalic acid-adipic acid-ethylene glycol-polyethylene glycol copolyester, Polyethylene glycol monomer units account for 30% of the quality of polyethylene terephthalic acid-adipic acid-ethylene glycol-polyethylene glycol copolyester, wherein the number-average molecular weight of polyethylene glycol monomer units is 1000, a total of Polyester intrinsic viscosity 0.6dL / g) and spandex chip (polyether type, tensile strength 32MPa, elongation at break 800%) make water-swelling fiber chip component and spandex chip component cross-sectional area by compound spinning machine and be 1 :2 The side-by-side composite fiber is the water-swellable deformed fiber.

[0091] (2) be 2dtex, ...

Embodiment 2

[0094] A preparation method of a tassel-shaped temporary plugging agent applied to both ends of temporary plugging fracturing is as follows:

[0095] (1) Preparation of water-swellable deformed fiber: Slice the water-swellable fiber (the mass of adipate monomer unit accounts for 10% of the mass of polyterephthalic acid-adipic acid-ethylene glycol-polyethylene glycol copolyester, Polyethylene glycol monomer units account for 30% of the quality of polyethylene terephthalic acid-adipic acid-ethylene glycol-polyethylene glycol copolyester, wherein the number-average molecular weight of polyethylene glycol monomer units is 3000, a total of Polyester intrinsic viscosity 0.8dL / g) and spandex chip (polyester type, tensile strength 30MPa, elongation at break 300%) make water-swellable fiber chip component and spandex chip component cross-sectional area by compound spinning machine and be 2 :1 The side-by-side composite fiber is the water-swellable deformed fiber.

[0096] (2) The wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com