Energy-saving high-efficient electrolytic aluminum waste gas treatment device

A technology of waste gas treatment device and electrolysis device, which is applied in gas treatment, steam engine device, steam condensation, etc., can solve problems such as heat leakage, and achieve the effect of increasing economic value and increasing income sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

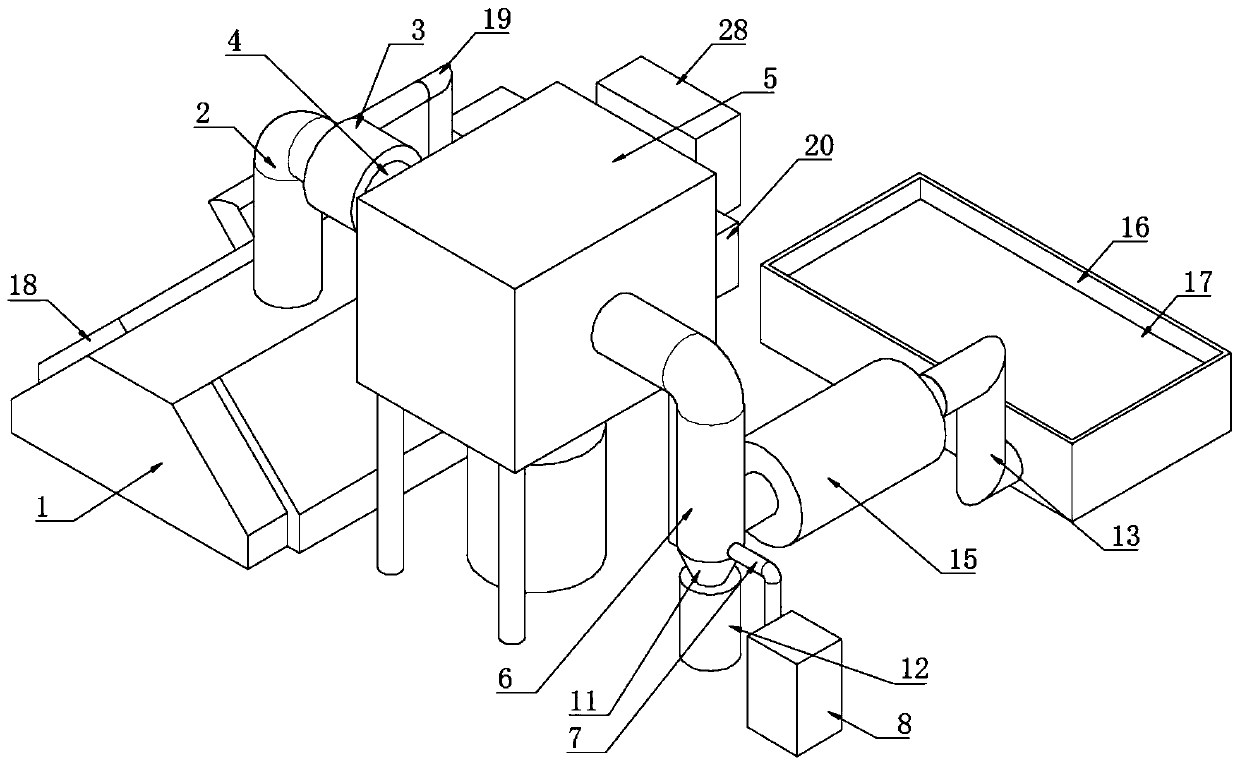

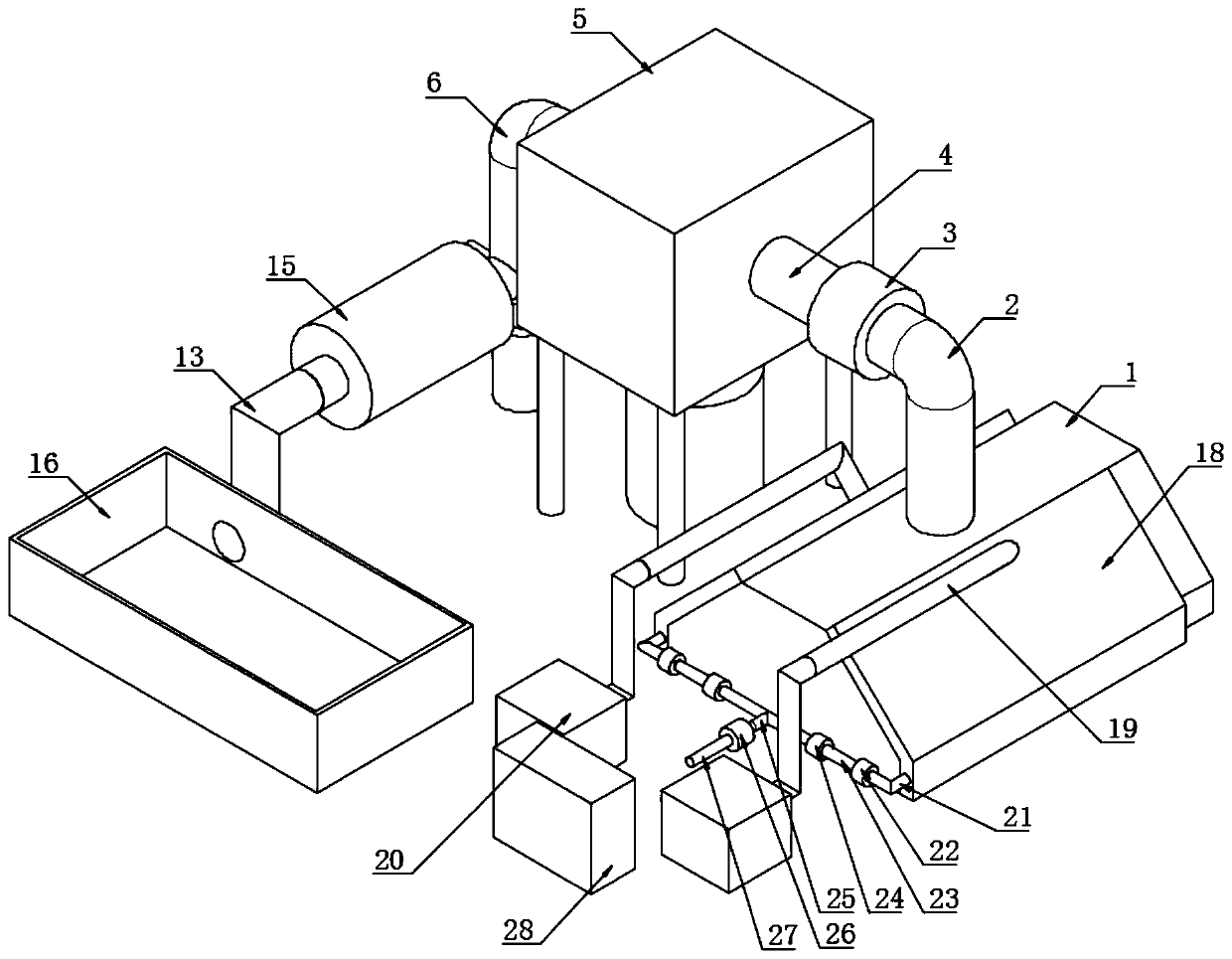

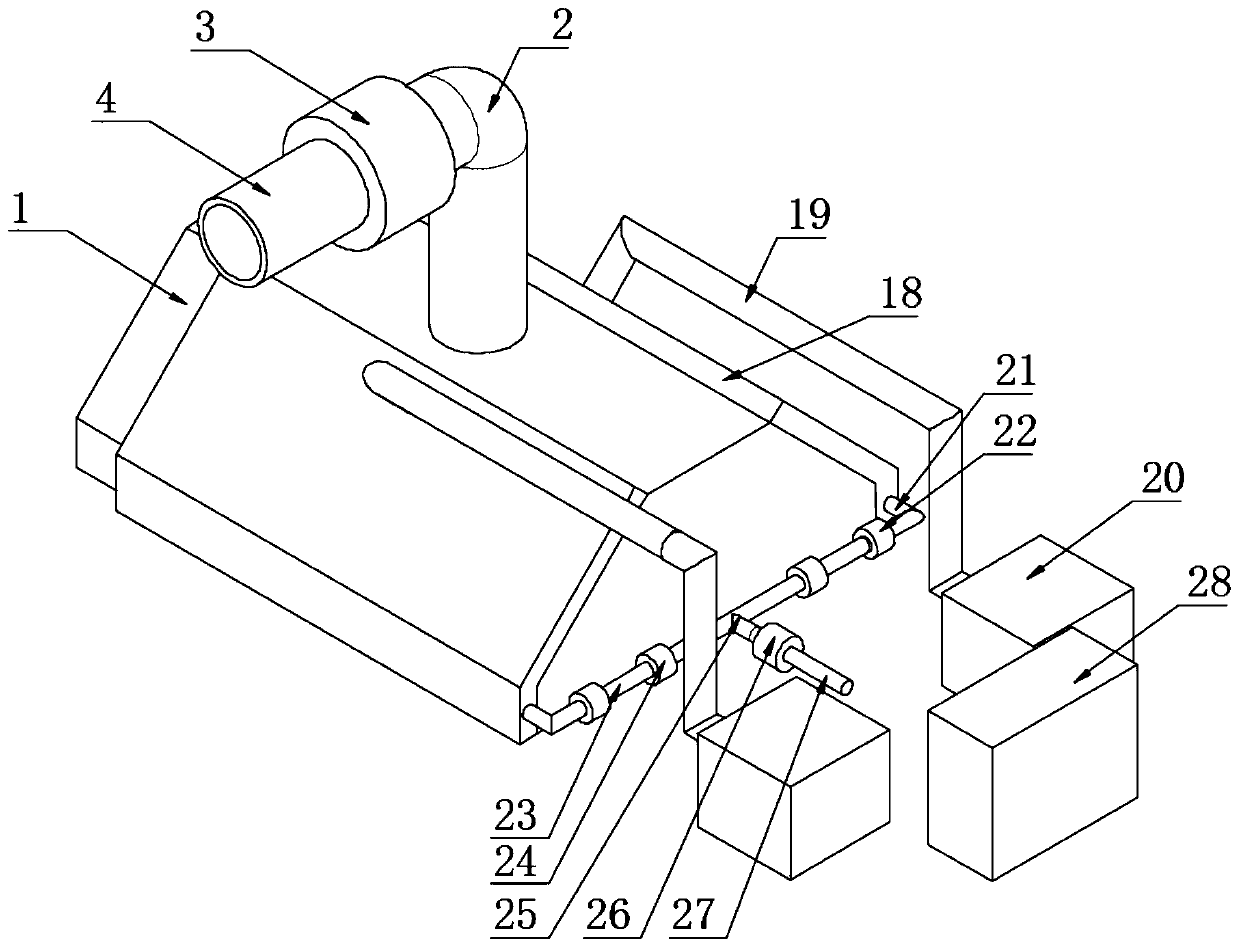

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] The present invention provides such Figure 1-7 The shown energy-saving and high-efficiency electrolytic aluminum waste gas treatment device includes an electrolysis device 1, a first pipe 2 is fixedly connected to the top of the electrolysis device 1, and an axial flow fan 3 is fixedly connected to the end of the first pipe 2 away from the electrolysis device 1 The end of the axial flow fan 3 far away from the first pipe 2 is fixedly connected with a second pipe 4, and the end of the second pipe 4 far away from the axial flow fan 3 is fixedly connected with a bag filter 5, and one side of the outer wall of the bag filter 5 is A third pipe 6 is fixedly connected, and an outlet pipe 7 runs through one side of the inner wall of the third pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com