Window opening forming superimposed shear wall coupling beam assembling construction method

A technology of superimposed shear walls and construction methods, applied to walls, building components, building materials, etc., can solve problems such as insufficient shear bearing capacity, inability to effectively protect wall limbs, and increased construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

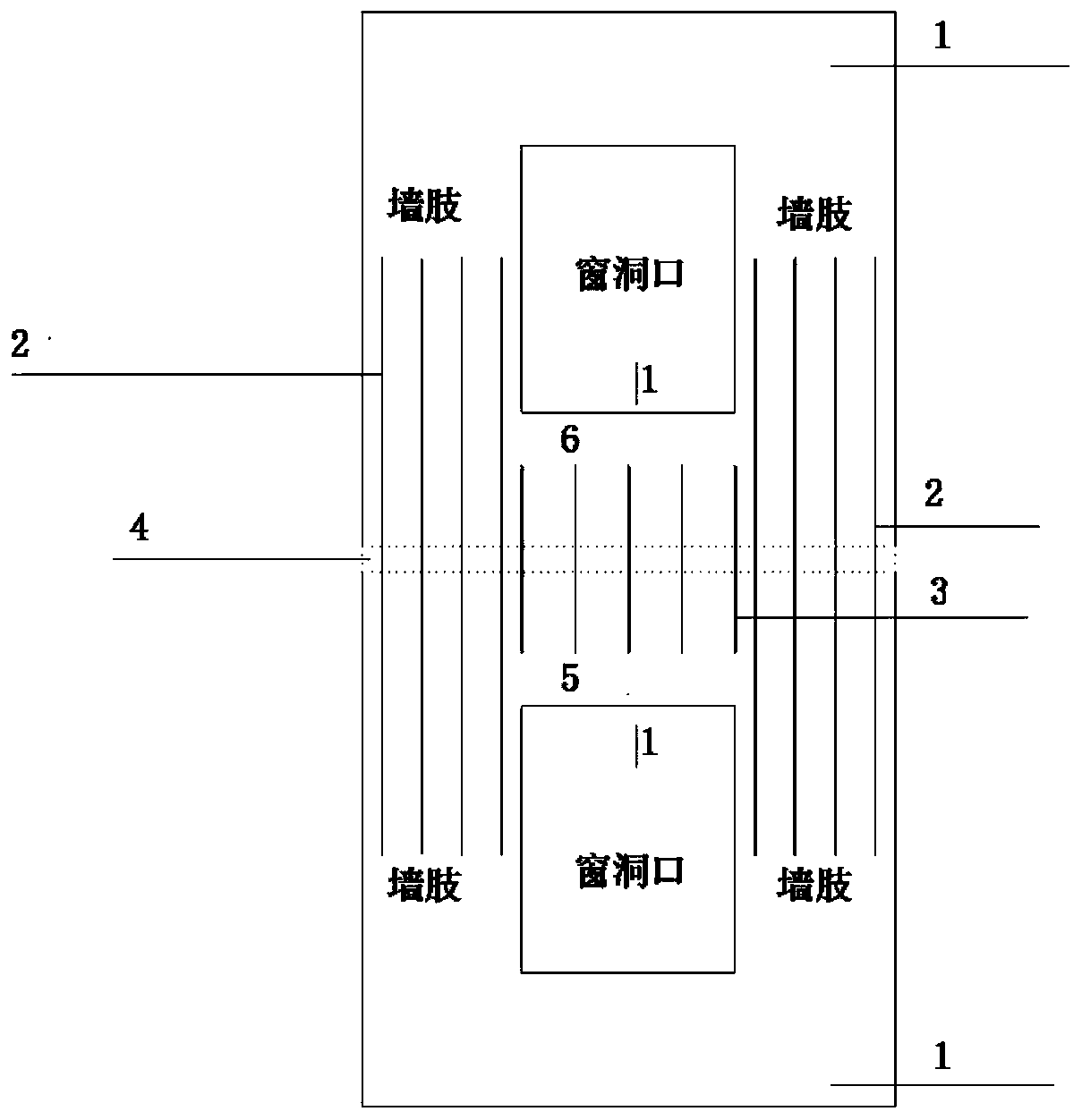

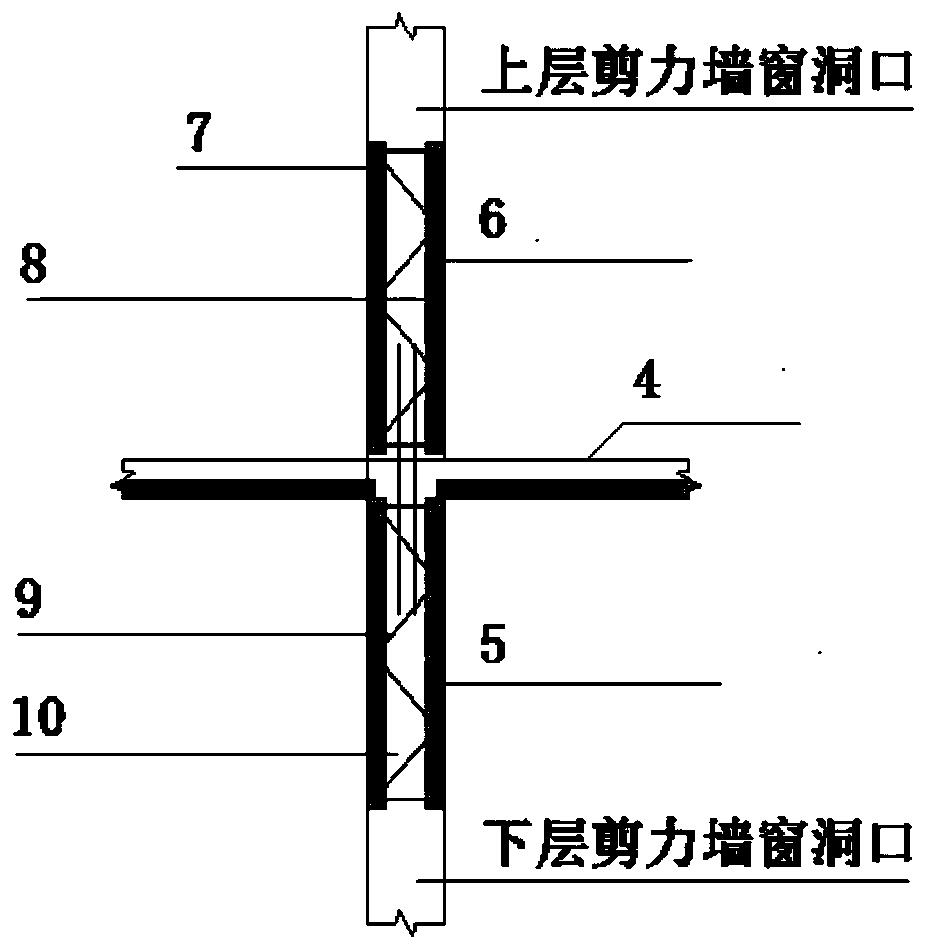

[0022] Such as figure 1 with figure 2 Shown is a double-sided laminated shear wall structure with a window opening, including prefabricated double-sided laminated shear wall panel 1 with a window opening, vertical connection reinforcement bars 2 for wall piers, vertical connection reinforcement reinforcement bars 3 for connecting beams, stacked Composite floor slab 4, post-cast core layer concrete 10. The prefabricated window-opening laminated shear wall panel 1 consists of a prefabricated inner leaf wall panel, a prefabricated outer leaf wall panel and a vertically arranged steel bar truss 9 connecting the inner and outer wall panels, and the prefabricated inner and outer leaf wall panels are arranged with Longitudinal and horizontal distribution of steel bars, among them, the layout of vertical and horizontal force-bearing steel bars in the laminated shear wall panel 1 with window openings must meet the requirements of the code. The prefabricated window opening laminated ...

Embodiment 2

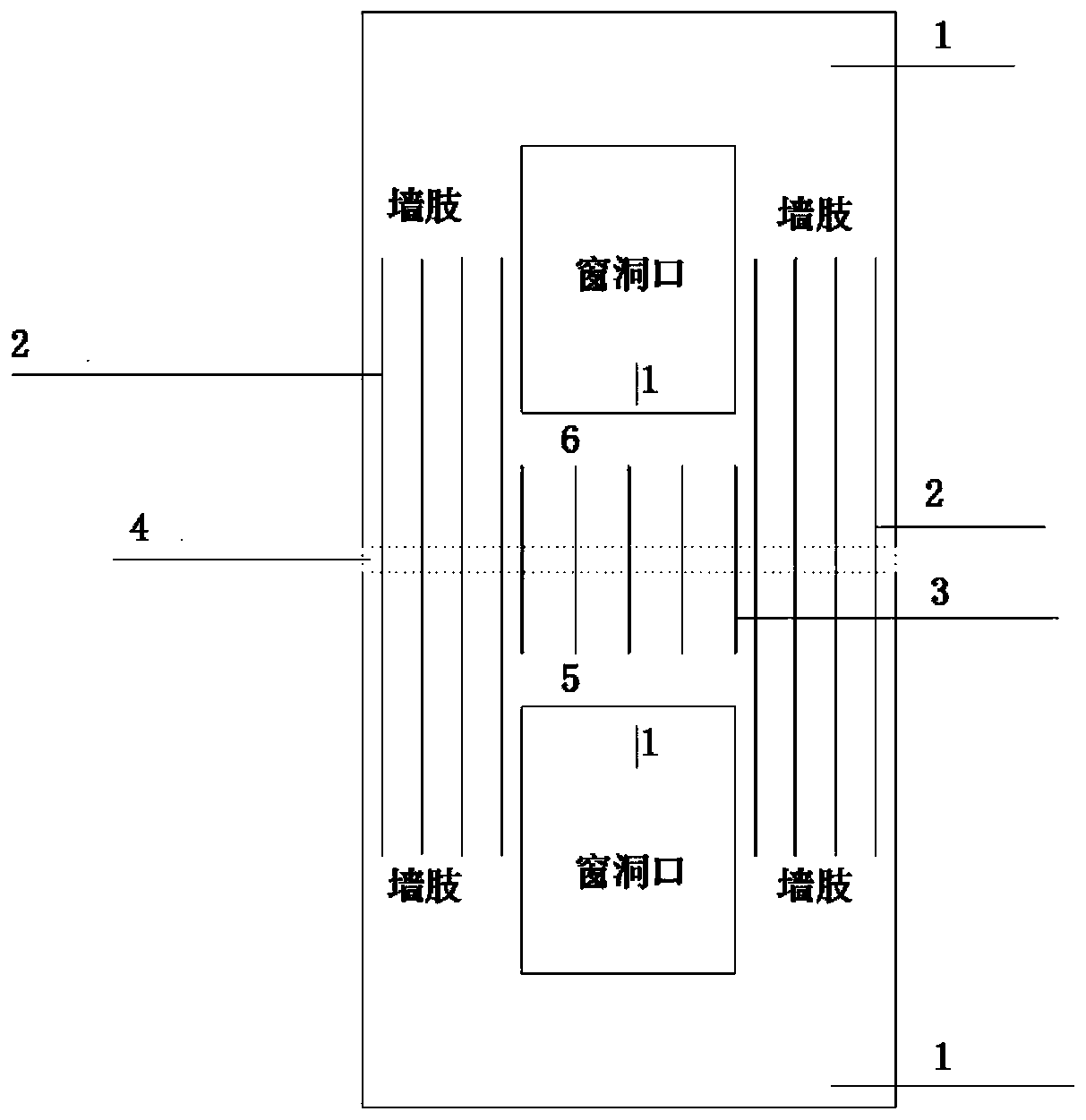

[0029] Embodiment 2 is a single-sided laminated shear wall structure with window openings. Such as Figure 3 to Figure 4 The upper and lower laminated deep connecting beam single-sided laminated shear wall structure includes precast concrete window hole laminated shear wall panel 1, vertical connecting steel bars 2 of wall piers, vertical connecting steel bars 3 of connecting beams, Laminated floor 4, post-cast concrete 10. The above prefabricated concrete laminated shear wall panels are provided with window upper wall connecting beams 5 and window lower wall connecting beams 6, and the connecting beams are provided with stirrup bars 7, longitudinal stress bars 8, truss steel bars 9, and FRP insulation connectors 11. Insulation board 12 and outer leaf board 13. Laminated shear wall panels 1 with window openings include prefabricated laminated wall panels for the inner and outer leaves, steel bar trusses 9, FRP insulation connectors 11 and insulation panels 12 connecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com