Yellow front plate glass for photovoltaic module and yellow photovoltaic module prepared from yellow front plate glass

A technology of front glass and photovoltaic modules, which is applied in the field of solar cells, can solve the problems of poor aesthetics and single color, and achieve the effects of low cost, simple preparation process, and small number of film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

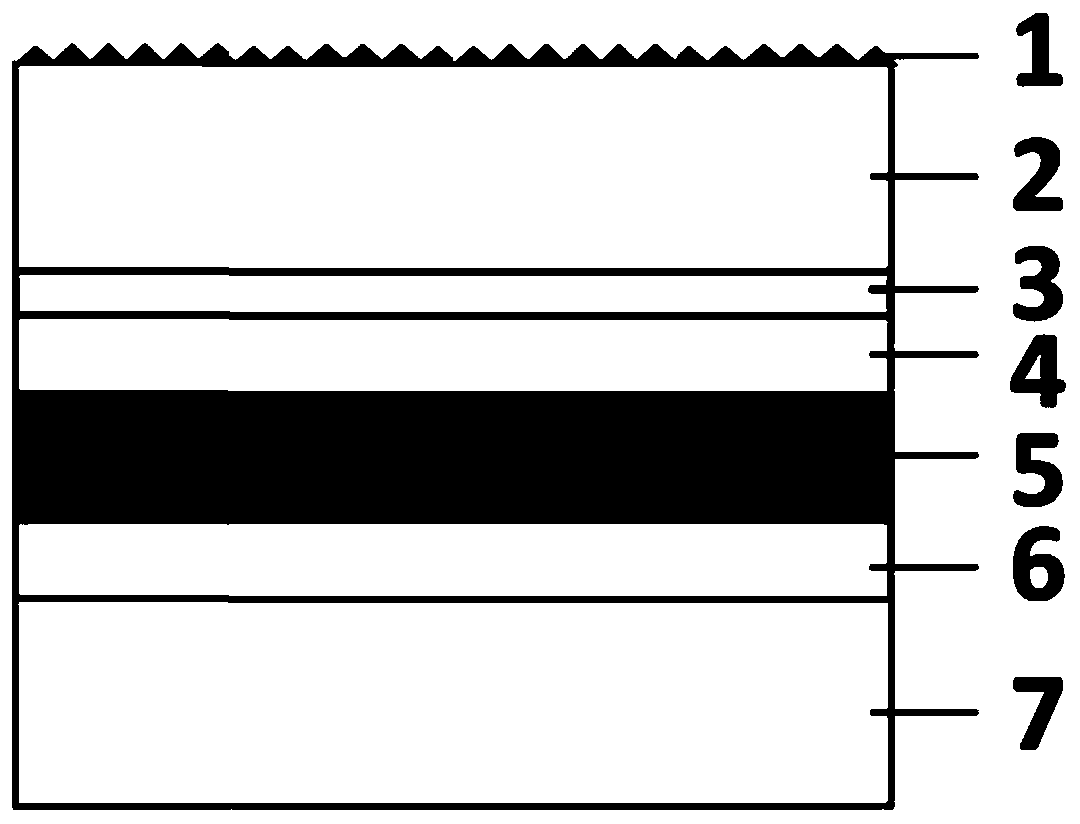

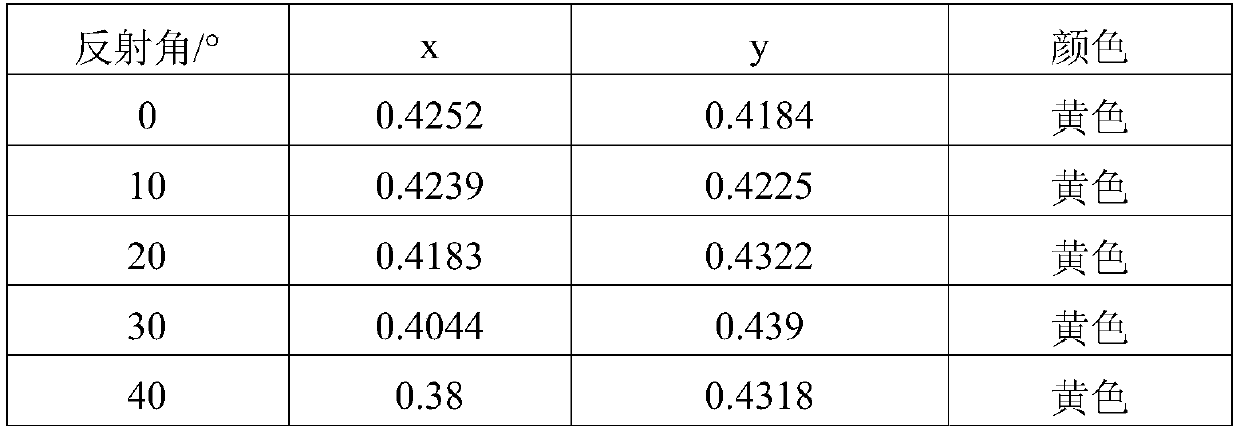

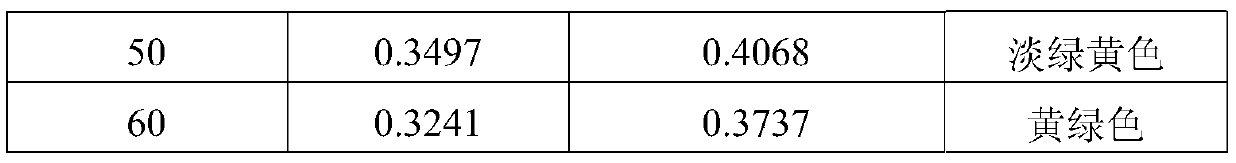

[0051] The yellow front plate glass described in this embodiment includes a glass substrate and a yellow dielectric film block with a three-layer structure design, and the specific structure design is: air / / glass substrate / / high refractive index material H / / low refractive index material L / / high Refractive index material H / / organic polymer, where:

[0052] The first functional layer (H): that is, made of high refractive index material Si 3 N 4 (n at 550nm H =1.92) formed high refractive index layer H, the thickness is 90nm;

[0053] The second functional layer (L): that is, made of low refractive index material SiO 2 (n at 550nm L =1.45) formed low refractive index layer L, the thickness is 110nm;

[0054] The third functional layer (H): that is, made of high refractive index material Si 3 N 4 (n at 550nm H =1.92) to form a high refractive index layer H with a thickness of 90 nm.

[0055] The glass substrate is ultra-clear tempered glass with a thickness of 5mm and a r...

Embodiment 2

[0066] The yellow front plate glass described in this embodiment includes a glass substrate and a yellow dielectric film block with a three-layer structure design, and the specific structure design is: air / / glass substrate / / high refractive index material H / / low refractive index material L / / high Refractive index material H / / organic polymer, where:

[0067] The first functional layer (H): made of high refractive index material TiO 2 (n at 550nm H =2.32) formed high refractive index layer H, the thickness is 90nm;

[0068] The second functional layer (L): that is, made of low refractive index material SiO 2 (n at 550nm L =1.45) formed low refractive index layer L, the thickness is 30nm;

[0069] The third functional layer (H): that is, made of high refractive index material TiO 2 (n at 550nm H =2.32) to form a high refractive index layer H with a thickness of 100 nm.

[0070] The glass substrate is ultra-clear tempered glass with a thickness of 5mm and a refractive index o...

Embodiment 3

[0081] The yellow front plate glass described in this embodiment includes a glass substrate and a yellow dielectric film block designed with a 5-layer structure, and the specific structure is designed as: air / / glass substrate / / high refractive index material H / / low refractive index material L / / high Refractive index material H / / low refractive index material L / / high refractive index material H / / organic polymer, where:

[0082] The first functional layer (H): that is, made of high refractive index material Si 3 N 4 (n at 550nm H =1.92) formed high refractive index layer H, the thickness is 40nm;

[0083] The second functional layer (L): that is, made of low refractive index material SiO 2 (n at 550nm L =1.45) formed low refractive index layer L, the thickness is 65nm;

[0084] The third functional layer (H): that is, made of high refractive index material Si 3 N 4 (n at 550nm H =1.92) formed high refractive index layer H, the thickness is 110nm;

[0085] The fourth functi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com