Piezoelectric sensor

A piezoelectric sensor and piezoelectric film technology, applied in the field of sensors, can solve the problems of low sensitivity of piezoelectric sensors affecting sensor performance, etc., and achieve ideal softness and impact strength, good flexural deformation, and low flexural modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

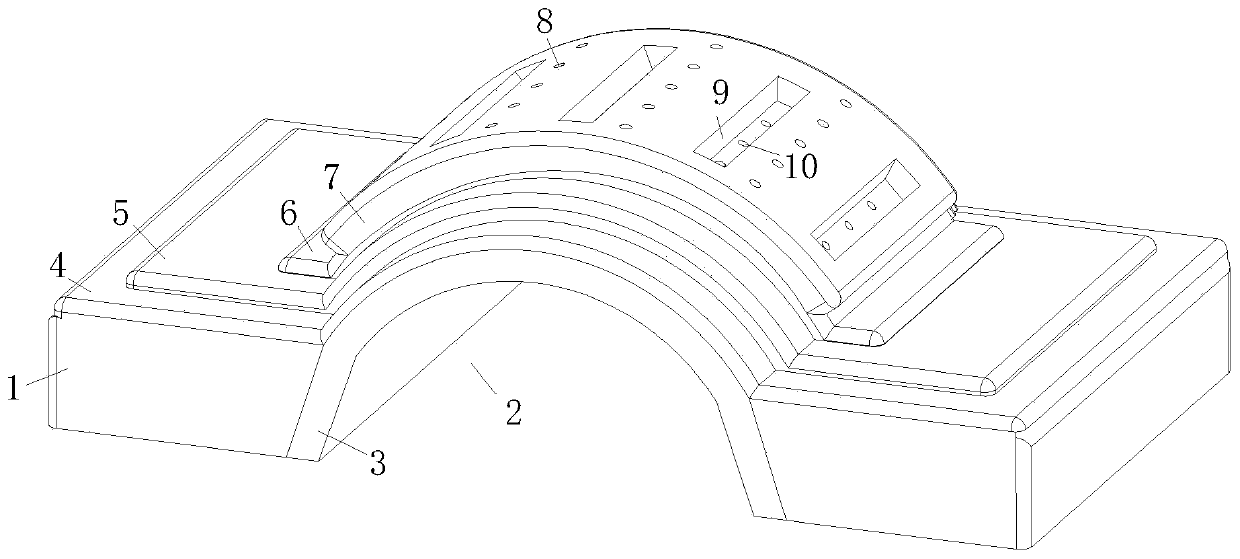

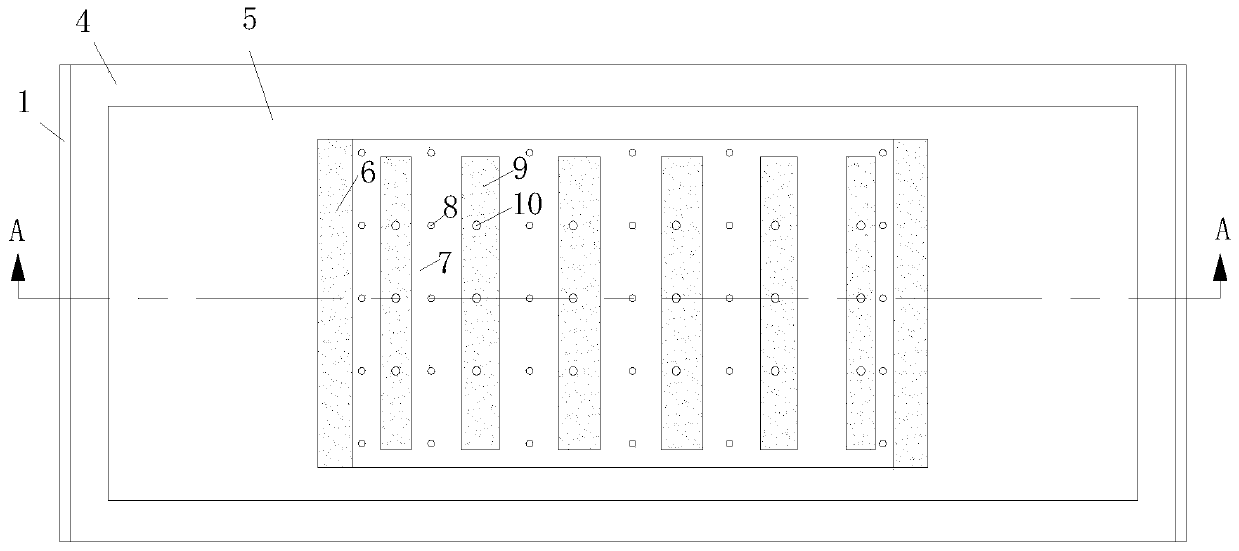

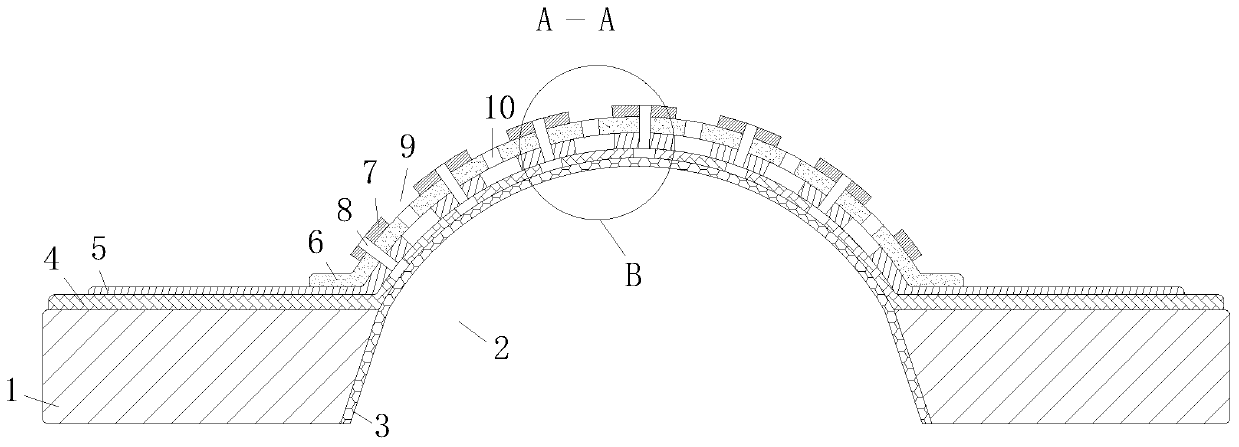

[0027]As an embodiment of the present invention, the piezoelectric thin film 6 is a laminate formed by laminating a plurality of film-like piezoelectric bodies, and the film-like piezoelectric body is a vinylidene fluoride-tetrafluoroethylene-based copolymer. electric body; the existing piezoelectric film 6 is mostly made of polyvinylidene fluoride material, and the voltage of the electrical signal actually measured has a tendency that the smaller the frequency is, the lower the measured voltage is, and the larger the frequency is, the higher the measured voltage is. The invention uses vinylidene fluoride-tetrafluoroethylene copolymer to make piezoelectric film 6, which has a larger output electrical signal from ultra-low frequency to high frequency region than polyvinylidene fluoride material, so it can make piezoelectric film 6 The frequency dependence of the output electrical signal of the thin film 6 becomes smaller, which improves the sensitivity of the piezoelectric senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com