Zinc-containing monatomic catalyst as well as preparation method and application thereof

A catalyst and atomic technology, applied in the field of electrocatalysis, can solve the problems of low stability of zinc single-atom catalysts, complex and difficult to control the preparation process, unfriendly environment, etc., achieve good anti-poisoning ability, simple and controllable process, prevent zinc The effect of atomic agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 pure zinc single-atom catalyst: C-ZIF8-NH 3 Preparation of -800

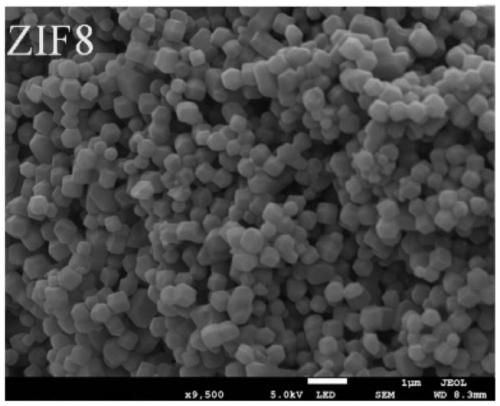

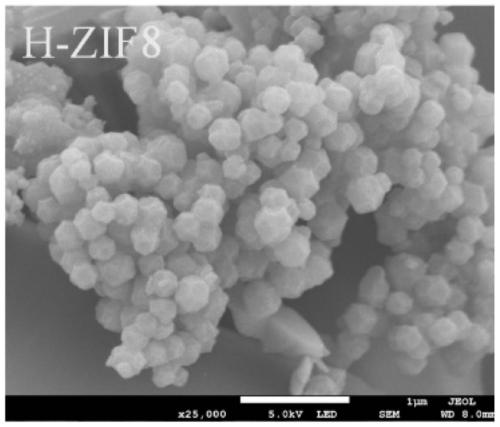

[0045] (1) 2-methylimidazole zinc salt (structure is: Named ZIF8) was calcined in a high-temperature tube furnace. Under a mixed atmosphere of hydrogen and nitrogen, the temperature was raised to 120°C at 2°C / min, and kept for 2h; then the temperature was raised to 300°C at 2°C / min, kept for 2h, and finally The temperature was raised to 600°C at 5°C / min, held for 3 hours, and cooled naturally to room temperature to obtain the zinc intermediate as a gray-black powder sample, which was named H-ZIF8.

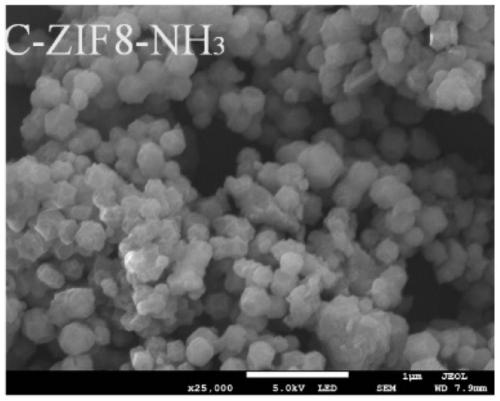

[0046] (2) Add H-ZIF8 (0.1 g) to 10 mL of ammonia water with a concentration of 28 wt%, stir for 24 hours, collect by filtration, and obtain the first zinc-containing solid, which is a black sample, named C-ZIF8-NH 3 .

[0047] (3) Under the protection of nitrogen, the C-ZIF8-NH 3 Put it in a high-temperature tube furnace, raise the temperature to 120°C at 2°C / min, and keep it for 2h; then ra...

Embodiment 2

[0051] Embodiment 2 pure zinc single-atom catalyst: preparation of C-ZIF8-NaOH-800

[0052] The preparation steps are the same as in Example 1, except that 10 mL of aqueous NaOH solution with a concentration of 28 wt % is used to replace 10 mL of aqueous ammonia with a concentration of 28 wt %.

Embodiment 3

[0053] Embodiment 3 pure zinc single-atom catalyst: C-ZIF8-H 2 SO 4 Preparation of -800

[0054] The preparation steps are the same as in Example 1, except that: 10 mL of 28 wt% H 2 SO 4 The aqueous solution replaced 10 mL of aqueous ammonia with a concentration of 28 wt%.

[0055] For the H-ZIF8 in the preparation process of Example 1, and the C-ZIF8-NH respectively prepared in Examples 1-3 3 -800, C-ZIF8-NaOH-800 and C-ZIF8-H 2 SO 4 -800 for X-ray diffraction (XRD) test, their test results are compared as Figure 8 shown. It can be seen that H-ZIF8 contains ZnO; after acid or alkali etching, ZnO (corresponding to the diffraction peak of PDF: 36-1451) completely disappears, and only the diffraction peak of amorphous carbon material; indicating that after etching, the Zn compound is highly dispersed, Therefore, the Zn in the final zinc-containing single-atom catalyst is highly dispersed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com