Solid/gas separation device with deflagration prevention and filter material burning prevention functions and working method

A separation device and filter material technology, applied in the direction of separation methods, chemical instruments and methods, combined devices, etc., can solve problems such as deflagration, and achieve the effect of avoiding deflagration accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

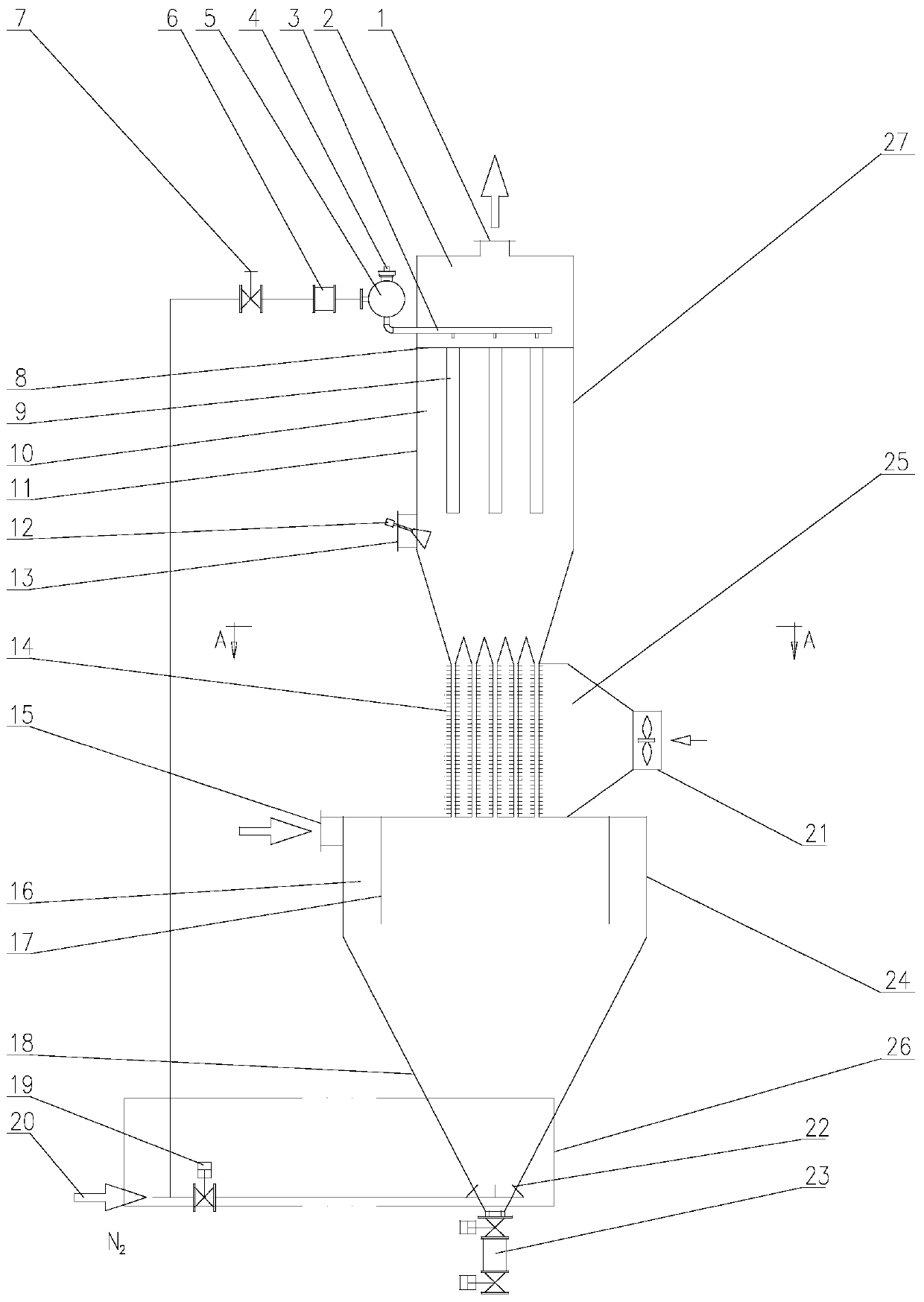

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0028] figure 1 It is a structural schematic diagram of an embodiment of the present invention. Such as figure 1 As shown, the solid / gas separation device with deflagration prevention and filter material scalding prevention in this embodiment includes a primary separation structure 24 , a cooling flame arresting structure 25 , an inert gas fluidized injection structure 26 and a fine filtering structure 27 .

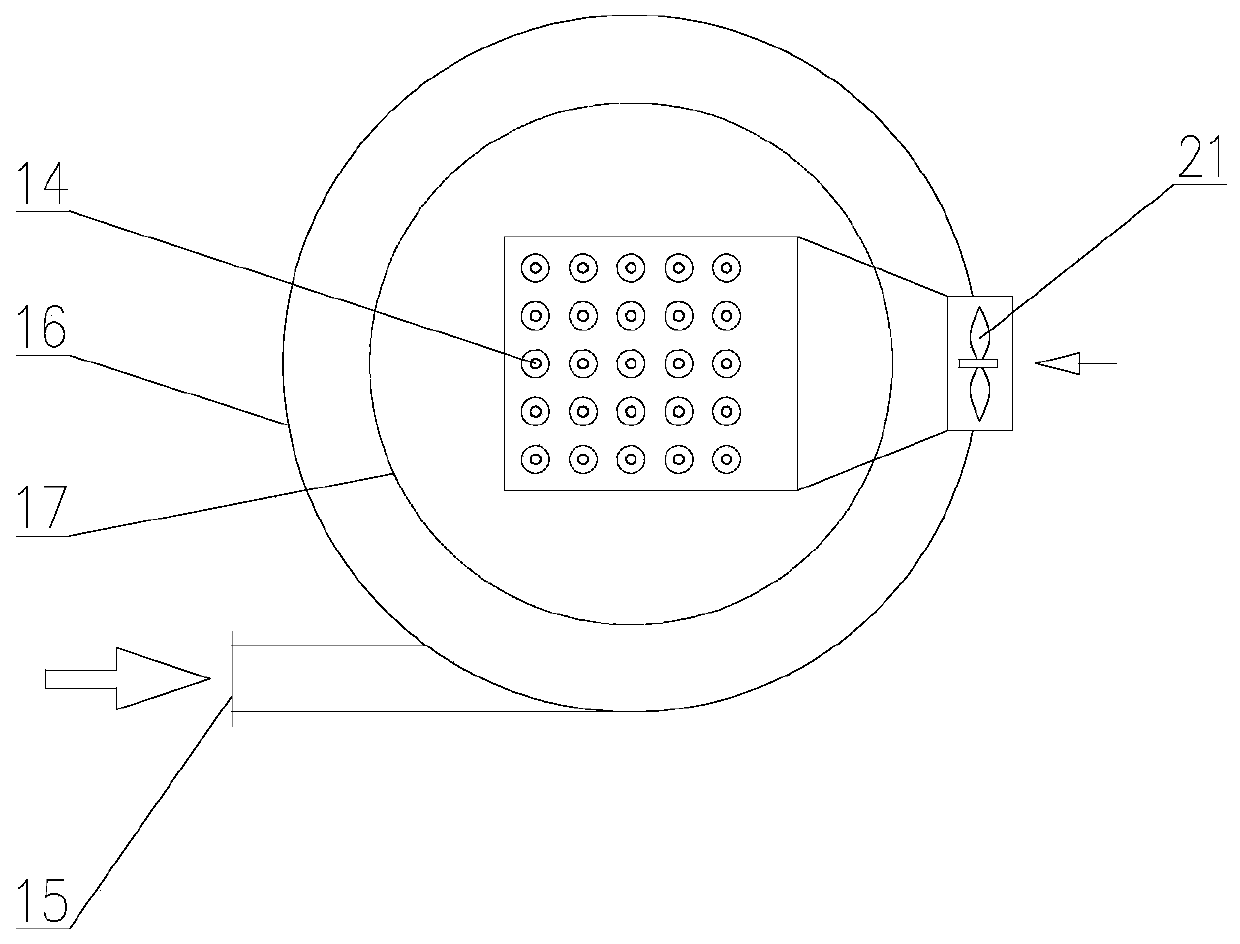

[0029] Primary separation structure 24 includes solids / cyclonic wind separation section 16 and ash hopper 18 .

[0030] The solid / cyclone wind separation section 16 mainly plays the role of solid / gas separation and sedimentation treatment for the dusty gas. A dusty air inlet 15 is provided on the side wall of the solid / cyclone separation section 16 . The dusty air inlet 15 is connected to the side wall of the solid / cyclone separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com