Spiral tube semi-solid slurry preparation integrated system

A semi-solid slurry, integrated system technology, used in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of easy introduction of external impurities, easy occurrence of "entrainment, and impact on slurry quality, etc." The effect of avoiding oxidation and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

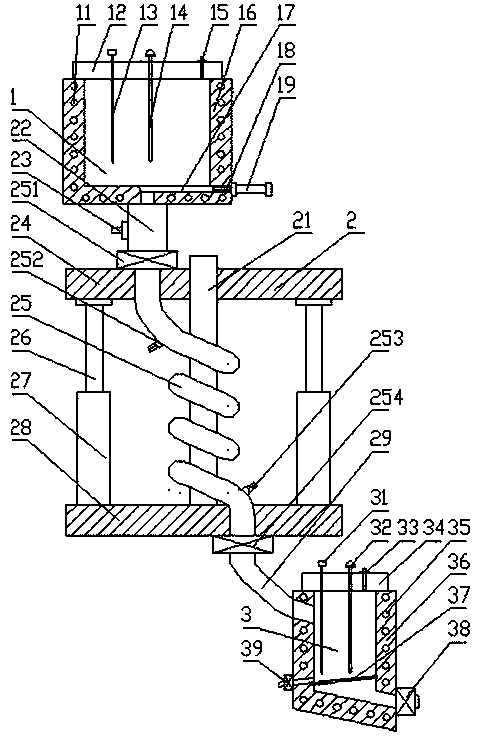

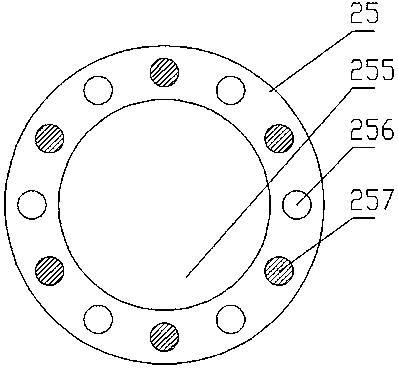

[0023] as attached figure 1 and 2 As shown, the spiral tube semi-solid slurry preparation integrated system of the present invention mainly includes a furnace component 1 , a spiral tube slurry preparation component 2 , and a slurry buffer component 3 .

[0024] The furnace assembly 1 includes a furnace body 16, a furnace cover 12, a slurry baffle 17, and a drive cylinder 19. The furnace cover 12 is arranged on the top of the furnace body 16, and the furnace cover 12 is provided with a temperature sensor I13 and a liquid level sensor I14 , Exhaust valve I15, temperature sensor I13 can measure the temperature in the furnace body 16 in real time, liquid level sensor I14 can measure the melt liquid level in the furnace body 16 in real time, and the exhaust valve I15 is connected with an external vacuum pump , the furnace body 16 can be evacuated, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com