Preparation method and purification process of fluorine-containing lithium sulfimide

A lithium sulfonyl imide and process technology, which is applied in the field of preparation of fluorine-containing lithium sulfonyl imide, can solve problems such as low product yield, potential safety hazards, and cumbersome preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

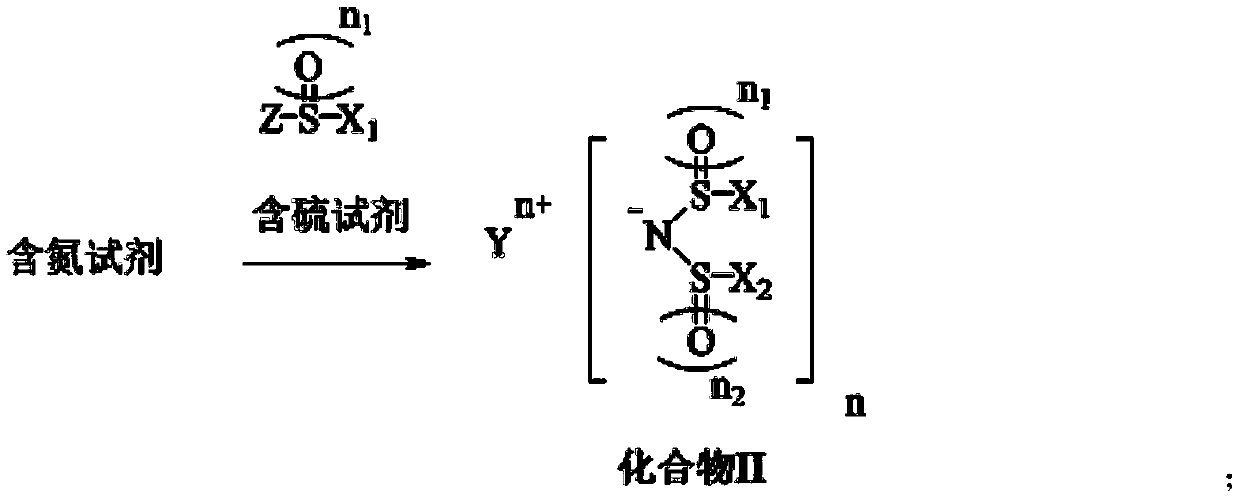

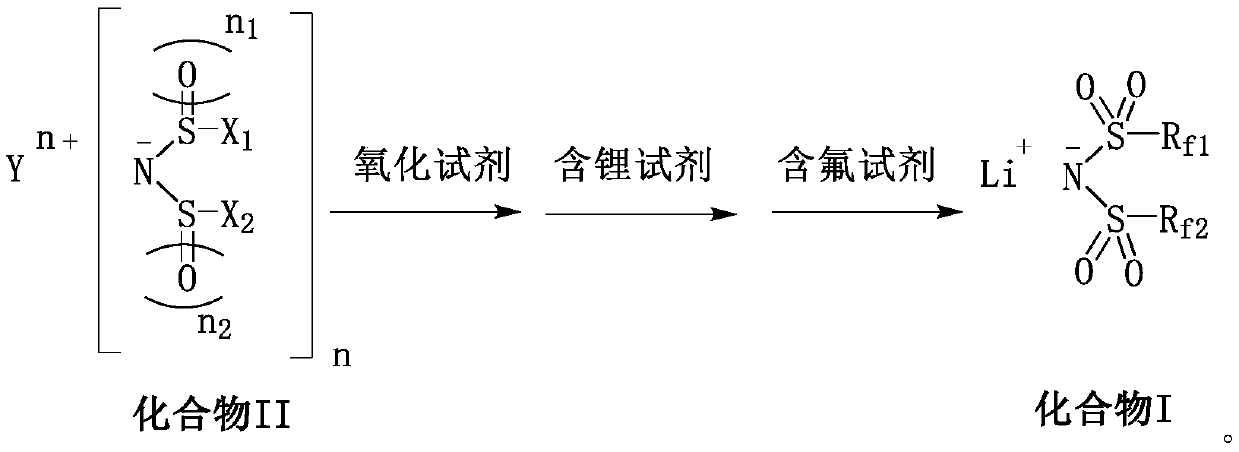

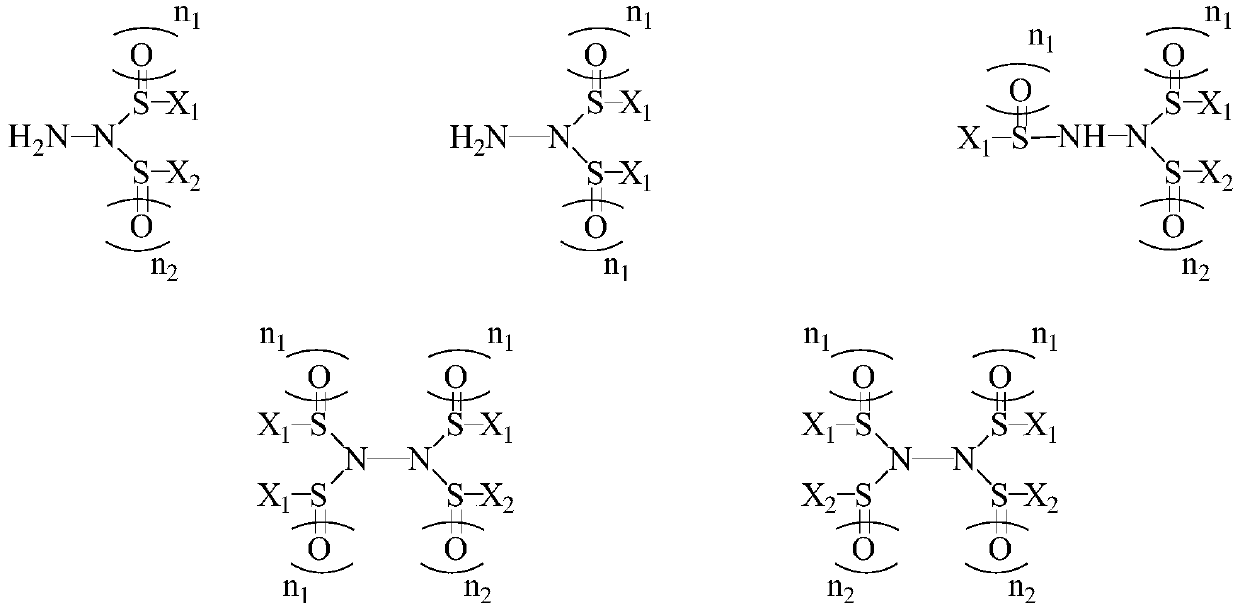

Method used

Image

Examples

Embodiment 1

[0066] The preparation method and purification process of lithium bistrifluoromethanesulfonyl imide comprise the following steps:

[0067] (1) Preparation process one:

[0068] Under stirring condition, add 100g nitrogen-containing substance trifluoromethanesulfonyl chloride, isopropanol, reaction solvent toluene in 1L dry reactor, the molar ratio of sulfur-containing substance trifluoromethanesulfinyl chloride, isopropanol respectively The ratio is 2.5:1, the reaction temperature is 70°C, the reaction pressure is 0.1MPa (gauge pressure), and the reaction time is 4h. After the reaction was completed, the temperature was lowered to normal temperature, the insoluble matter was filtered off, the filtrate was evaporated under reduced pressure to remove the solvent, concentrated, and the crude compound II was prepared;

[0069] (2) Preparation process two:

[0070] Under stirring conditions, add 100 g of compound II and toluene as a reaction solvent to a 1 L dry reactor, add fluo...

Embodiment 2

[0078] The preparation method and purification process of lithium bisfluorosulfonyl imide comprise the following steps:

[0079] (1) Preparation process one:

[0080] Under stirring condition, add 100g nitrogen-containing substance trifluoromethanesulfonyl chloride, isopropanol, reaction solvent toluene in 1L dry reactor, the molar ratio of sulfur-containing substance trifluoromethanesulfinyl chloride, isopropanol respectively The ratio is 2.5:1, the reaction temperature is 70°C, the reaction pressure is 0.1MPa (gauge pressure), and the reaction time is 4h. After the reaction was completed, it was lowered to normal temperature. The insolubles were removed by filtration, the filtrate was evaporated under reduced pressure to remove the solvent, concentrated, and the crude compound II was prepared;

[0081] (3) Preparation process two:

[0082] Under stirring conditions, add 100 g of compound II and toluene as a reaction solvent to a 1 L dry reactor, add the oxidizing substanc...

Embodiment 3

[0090] Preparation and Purification Process of Lithium Bisperfluoroethylsulfonylimide

[0091] (1) Preparation process one:

[0092] Under stirring conditions, add 100g of nitrogen-containing substance perfluoroethylsulfinyl chloride, isopropanol, and reaction solvent toluene to a 1L dry reactor, and the molar ratios of sulfur-containing substance perfluoroethylsulfinyl chloride and butyl acetate are respectively The ratio is 3:1, the reaction temperature is 80°C, the reaction pressure is 0MPa (gauge pressure), and the reaction time is 6h. After the reaction was completed, the temperature was lowered to normal temperature, the insoluble matter was filtered off, the filtrate was evaporated under reduced pressure to remove the solvent, concentrated, and the crude compound II was prepared;

[0093] (2) Preparation process two:

[0094] Under stirring conditions, add 100 g of compound II and butyl acetate as a reaction solvent into a 1 L dry reactor, and add the fluorine-contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com