Mineral admixture prepared from solid waste and preparation method thereof

A technology of mineral admixtures and solid wastes, which is applied in the field of resource utilization to achieve the effects of improving performance, promoting early hydration, and improving activity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a mineral admixture prepared from solid waste, the specific steps are as follows:

[0046] The polishing powder for processing natural granite stones for architectural decoration is first vacuum-filtered and then dried to a moisture content of 1.6%, and the tailings slag from mining lead-zinc ore is first dried to a moisture content of 1.0%; 40wt% waste stone chips (powder) of limestone crushed stones for mining and construction, 15wt% tailings slag from mining lead-zinc mines, and 20wt% converter steelmaking bottom slag are metered and batched, and then mixed and ground with a ball mill; the obtained The mixture is measured and dosed according to mass percentage 75wt% and polishing powder 25wt% of processed natural granite stone for architectural decoration, and then stirred and mixed evenly to obtain the mineral admixture.

Embodiment 2

[0048] A method for preparing a mineral admixture prepared from solid waste, the specific steps are as follows:

[0049] The polishing powder of the natural metamorphic chlorite schist used for processing architectural decoration is vacuum-filtered and then dried to a moisture content of 2.0%, and the tailings slag from the mining of lead-zinc ore is first dried to a moisture content of 1.5%; Mass percentage, after 30% of waste stone chips (powder) of granite gravel for mining and construction, 20wt% of tailings slag of mining lead-zinc ore, and 20wt% of converter steelmaking furnace bottom slag are measured and batched, a ball mill is used for mixed grinding; The mixture obtained after grinding is then measured and dosed according to 70wt% by mass and 30wt% of polishing powder for processing natural metamorphic chlorite schist stone for architectural decoration, and then stirred and mixed evenly to obtain the mineral admixture.

Embodiment 3

[0051] A method for preparing a mineral admixture prepared from solid waste, the specific steps are as follows:

[0052] The polishing powder for processing natural marble stone for architectural decoration is first vacuum-filtered and then dried to a moisture content of 1.8%, and the tailings slag from mining lead-zinc ore is first dried to a moisture content of 1.2%; 20wt% of waste stone chips (powder) of granite crushed stones for mining and construction, 30wt% of tailings slag from mining lead-zinc mines, and 30wt% of converter steelmaking furnace bottom slag are measured and batched, and mixed and ground by ball mills; the obtained The mixture is measured and dosed according to mass percentage of 80wt% and polishing powder of processed natural marble stone for architectural decoration 20wt%, and then stirred and mixed evenly to obtain the mineral admixture.

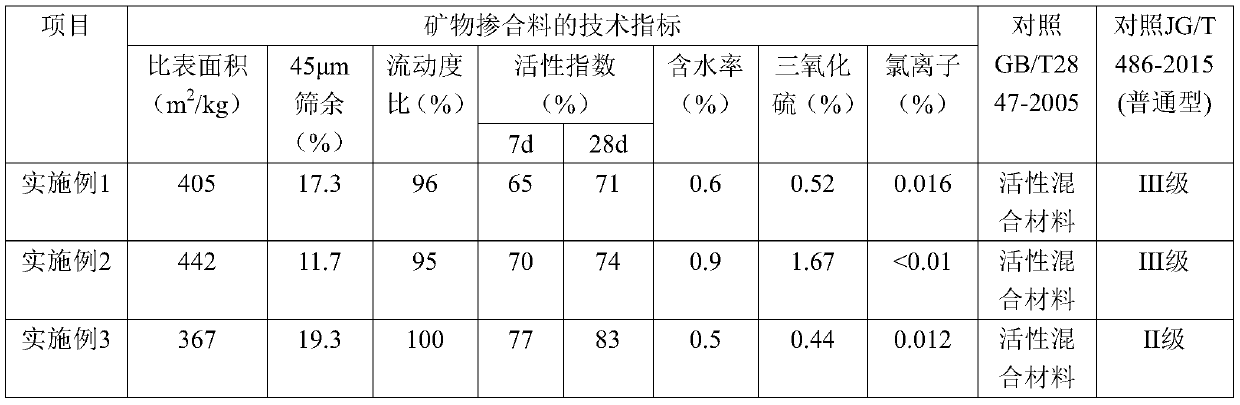

[0053] Table 1 shows the performance index parameters of the mineral admixture prepared from solid waste in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com