Hot-melt pressure-sensitive adhesive for normal-temperature waterproof roll butt-joint adhesive tape, and preparation method thereof

A technology of hot-melt pressure-sensitive adhesives and waterproof membranes, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of insufficient adhesion of non-polar materials and achieve improved thermal stability and compatibility, reduced impact, and improved pressure-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

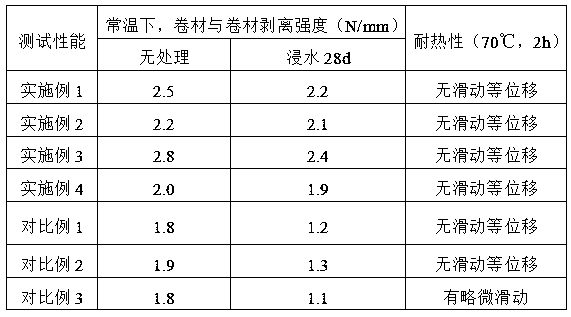

Examples

Embodiment 1

[0021] A hot-melt pressure-sensitive adhesive used for waterproof roll-to-fold tapes at room temperature, comprising the following components in parts by weight: 55 parts of SIS thermoplastic elastomer, 25 parts of polyisobutylene, 7 parts of hydrogenated monomer resin, tackifying resin complex 12 parts of compound, 1.5 parts of antioxidant and 1 part of ultraviolet absorber, wherein, in the SIS thermoplastic elastomer, the content of polystyrene is 15 wt%, and the content of polystyrene-polyisoprene diblock is 0 wt%. ~33wt%; the weight average molecular weight of the polyisobutylene is less than 2000, and the pour point is 3°C to -30°C; the tackifying resin compound is a compound of hydrogenated C9 petroleum resin and hydrogenated C5 petroleum resin, The mass ratio of the two is 1:1; the antioxidant is antioxidant 1010; and the ultraviolet absorber is UV-328.

[0022] The preparation method of the above-mentioned hot-melt pressure-sensitive adhesive is specifically as follows...

Embodiment 2

[0025] A hot-melt pressure-sensitive adhesive used for waterproof roll-to-fold tapes at room temperature, comprising the following components in parts by weight: 50 parts of SIS thermoplastic elastomer, 20 parts of polyisobutylene, 5 parts of hydrogenated monomer resin, and tackifying resin complex 10 parts of compound, 1 part of antioxidant and 0.5 part of ultraviolet absorber, wherein, in the SIS thermoplastic elastomer, the content of polystyrene is 15 wt%, and the content of polystyrene-polyisoprene diblock is 0 wt%. ~33wt%; the weight average molecular weight of the polyisobutylene is less than 2000, and the pour point is 3°C to -30°C; the tackifying resin compound is a compound of hydrogenated C9 petroleum resin and hydrogenated C5 petroleum resin, The mass ratio of the two is 2:1; the antioxidant is antioxidant 168; and the ultraviolet absorber is UV-P.

[0026] The preparation method of the above-mentioned hot-melt pressure-sensitive adhesive is specifically as follows...

Embodiment 3

[0029] A hot-melt pressure-sensitive adhesive for waterproof roll-to-fold adhesive tapes at room temperature, comprising the following components in parts by weight: 60 parts of SIS thermoplastic elastomer, 30 parts of polyisobutylene, 10 parts of hydrogenated monomer resin, tackifying resin complex 15 parts of compound, 2 parts of antioxidant and 1.5 parts of ultraviolet absorber, wherein, in the SIS thermoplastic elastomer, the content of polystyrene is 15 wt%, and the content of polystyrene-polyisoprene diblock is 0 wt%. ~33wt%; the weight average molecular weight of the polyisobutylene is less than 2000, and the pour point is 3°C to -30°C; the tackifying resin compound is a compound of hydrogenated C9 petroleum resin and hydrogenated C5 petroleum resin, The mass ratio of the two is 1.5:1; the antioxidant is antioxidant 1010 and antioxidant 168 (mass ratio 1:1); the ultraviolet absorber is UV-328 and UV-P (mass than 1:1).

[0030] The preparation method of the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com