Method for preparing PHA from corn steep liquor as raw material through fermentation

A technology for corn steep liquor and enzymatic hydrolysis of corn, applied in the directions of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of hindering the PHA process, expensive fermentation raw materials, and high fermentation costs, reducing dosage and solving emissions. problems, the effect of improving fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

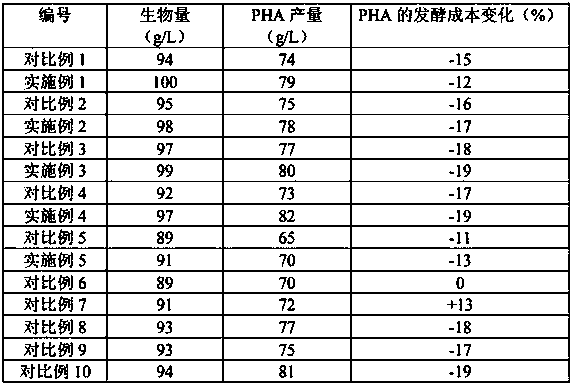

Examples

preparation example Construction

[0024] The preparation method of the enzymolyzed corn steep liquor comprises: enzymatically hydrolyzing corn steep liquor to obtain an enzymolyzed product, and then subjecting the enzymatically hydrolyzed product to solid-liquid separation to obtain the enzymatically hydrolyzed corn steep liquor;

[0025] Wherein, the enzymes used in the enzymatic hydrolysis are cellulase, hemicellulase, amylase and acid protease.

[0026] Corn steep liquor is one of the by-products of the corn deep processing industry. Corn steeping water is concentrated to obtain rice syrup. Corn steep liquor is a highly nutritious substance, and when the corn steep liquor is concentrated to a solid content of 40-50% by weight, the protein content will exceed 40% by weight. In addition, corn steep liquor also contains a variety of amino acids, vitamins, inorganic salts phosphorus, potassium and other nutrients.

[0027] Corn steep liquor is widely used. Corn steep liquor and corn husks are mixed and process...

Embodiment approach

[0029] According to a preferred embodiment of the present invention, the solid content of the corn steep liquor is 10-50% by weight (for example, 10% by weight, 15% by weight, 20% by weight, 25% by weight, 30% by weight, 35% by weight, 40% by weight, 45% by weight, 50% by weight, or any value in between), more preferably 40-50% by weight.

[0030] According to the present invention, the corn steep liquor can be any corn steep liquor that meets the above requirements in terms of solid content.

[0031] According to the present invention, the corn steep liquor may be corn steep liquor after impurity removal, or corn steep liquor without impurity removal. Preferably, the corn steep liquor is corn steep liquor after impurity removal.

[0032] According to the present invention, preferably, the impurity removal method is filtering.

[0033] More preferably, the filtering is selected from at least one of screen filtering, gauze filtering and vacuum filtering.

[0034] The present ...

preparation example 1

[0098] This preparation example is used to illustrate the activation of fermentation strains

[0099] Seed medium: containing 5g / L yeast powder, 10g / L peptone and 60g / L sodium chloride.

[0100] Halomonas was inoculated in the seed medium for primary activation culture at 37°C and 200rpm, and cultivated to OD 600 Reach about 4, obtain first-grade seed liquid;

[0101] The primary seed solution was inoculated into the seed medium with an inoculation amount of 10% by volume, and the secondary activation culture was carried out at 37°C and 200rpm, and cultivated to OD 600 Reach about 4, obtain secondary seed liquid, obtain fermented seed liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com