Antiseptic and antibacterial functional fiber and preparation process thereof

A functional fiber, anti-corrosion and anti-bacterial technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., to achieve good promotion and application value, convenient operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

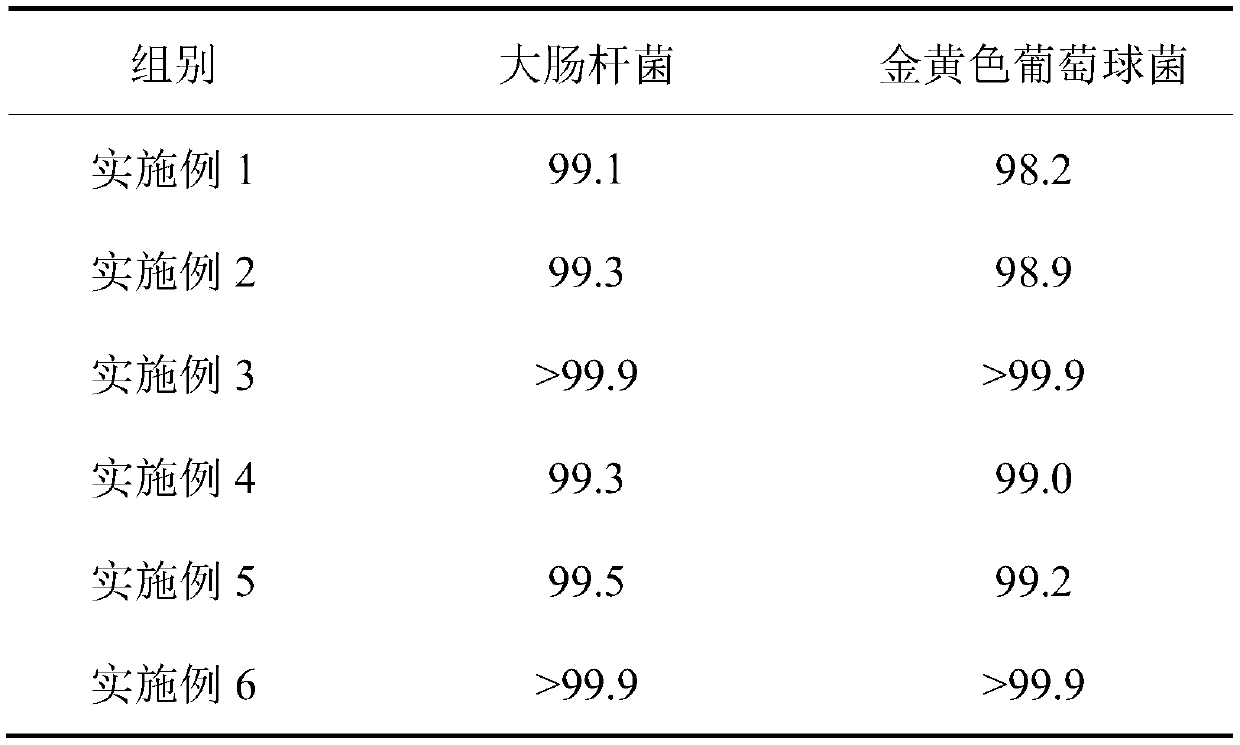

Examples

Embodiment 1

[0016] An anti-corrosion and anti-bacterial functional fiber is prepared by the following process: blending PET chips with anti-corrosion and anti-bacterial agents to obtain functional PET chips; melting, spinning and cooling the functional PET chips to obtain tubular hollow fibers; The hollow fiber is introduced into an immersion tank containing silver ammonia solution for immersion, and then dried to obtain the antiseptic and antibacterial functional fiber.

[0017] In the present embodiment, the configuration method of the silver-ammonia solution in the dipping tank is: add ammonia water dropwise to the silver nitrate solution of 8mmol / L, until the precipitate produced at first is just completely dissolved; the tubular hollow fiber in the dipping tank The impregnation time is 250s, and the tubular hollow fiber after impregnation is dried at 85° C. under the condition of air atmosphere.

[0018] In the present embodiment, the antiseptic and antibacterial agent is prepared by...

Embodiment 2

[0020] An anti-corrosion and anti-bacterial functional fiber is prepared by the following process: blending PET chips with anti-corrosion and anti-bacterial agents to obtain functional PET chips; melting, spinning and cooling the functional PET chips to obtain tubular hollow fibers; The hollow fiber is introduced into an immersion tank containing silver ammonia solution for immersion, and then dried to obtain the antiseptic and antibacterial functional fiber.

[0021] In the present embodiment, the configuration method of the silver-ammonia solution in the dipping tank is: add ammonia water dropwise to the silver nitrate solution of 8mmol / L, until the precipitate produced at first is just completely dissolved; the tubular hollow fiber in the dipping tank The impregnation time is 250s, and the tubular hollow fiber after impregnation is dried at 85° C. under the condition of air atmosphere.

[0022] In the present embodiment, the antiseptic and antibacterial agent is prepared by...

Embodiment 3

[0024] An anti-corrosion and anti-bacterial functional fiber is prepared by the following process: blending PET chips with anti-corrosion and anti-bacterial agents to obtain functional PET chips; melting, spinning and cooling the functional PET chips to obtain tubular hollow fibers; The hollow fiber is introduced into an immersion tank containing silver ammonia solution for immersion, and then dried to obtain the antiseptic and antibacterial functional fiber.

[0025] In the present embodiment, the configuration method of the silver-ammonia solution in the dipping tank is: add ammonia water dropwise to the silver nitrate solution of 8mmol / L, until the precipitate produced at first is just completely dissolved; the tubular hollow fiber in the dipping tank The impregnation time is 250s, and the tubular hollow fiber after impregnation is dried at 85° C. under the condition of air atmosphere.

[0026] In the present embodiment, the antiseptic and antibacterial agent is prepared by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com