Ecological protection structure for broken rock steep slope and construction method thereof

A technology for ecological protection and rock crushing, which is applied in infrastructure engineering, underwater structures, and botanical equipment and methods. Ability to slide down, improve microclimate, prevent slope instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

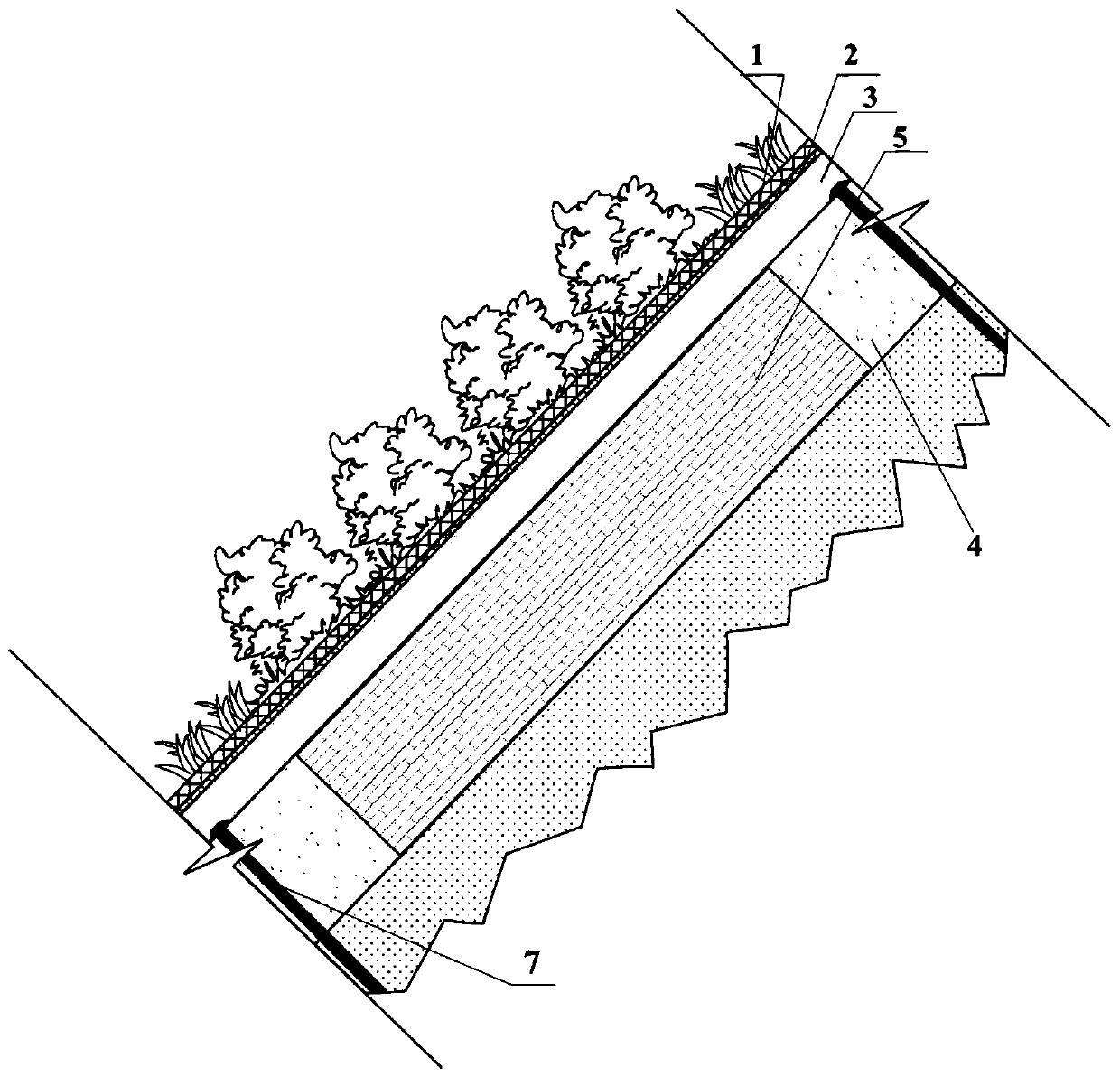

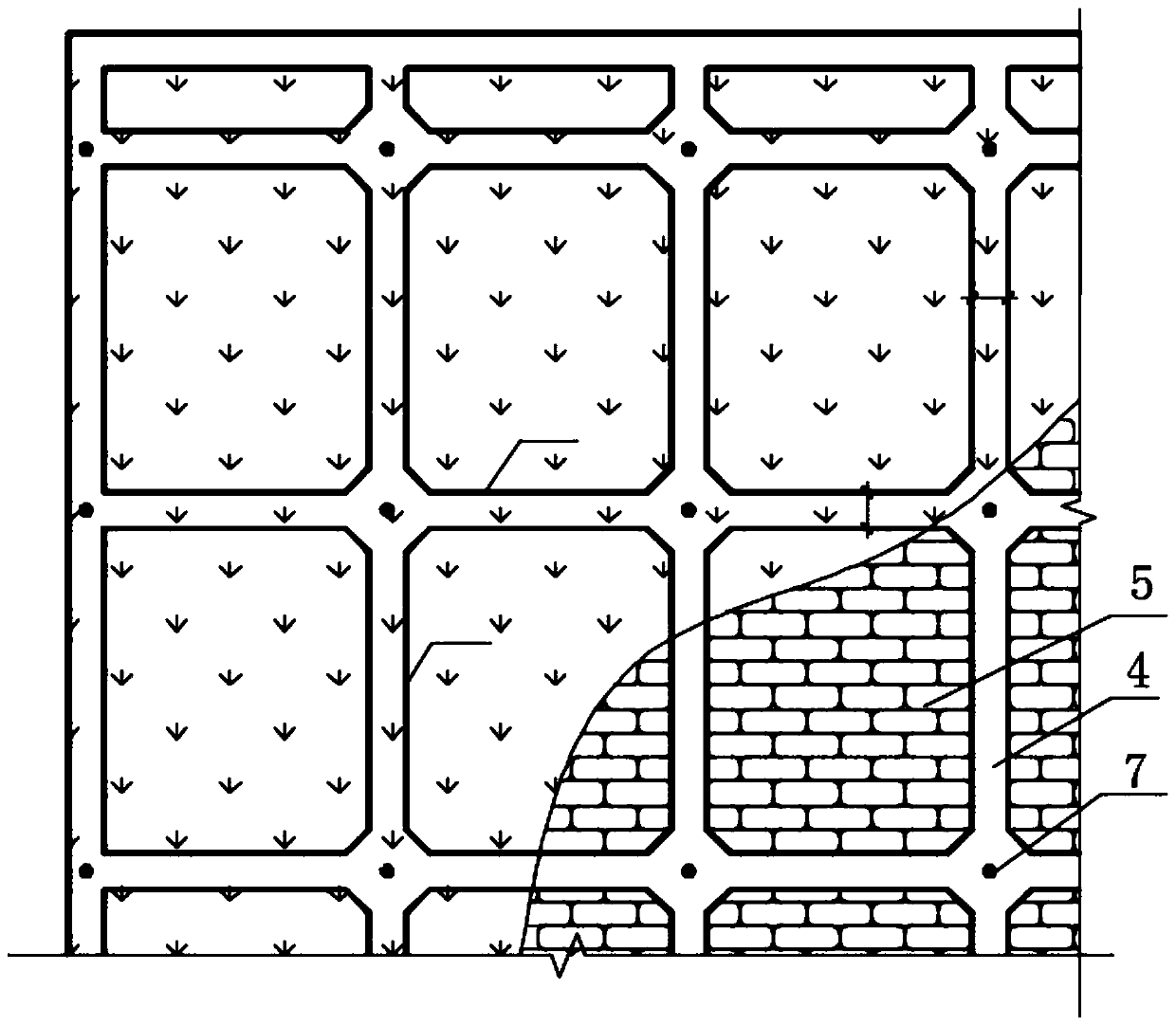

[0047] see figure 1 As shown, the present embodiment provides a kind of ecological protection structure of broken rocky steep slope, hereinafter referred to as slope protection, including seed soil layer 1, barbed wire 2 layers, nutrient soil base 3, and concrete lattice that are arranged on the slope from top to bottom successively. girders 4, such as image 3 As shown, the grid of the concrete lattice beam 4 is built with a planting bag 5 under the nutrient soil base 3 .

[0048] The uppermost seed soil layer 1 can provide early nutrients for plant growth, wherein the thickness of the seed soil layer 1 can be 20-30 mm.

[0049]The root system of the plant extends to the nutrient soil base 3 to further strengthen the strength and integrity of the nutrient soil base 3, wherein the thickness of the nutrient soil base 3 can be 80-90mm. The plant root system guides the infiltration of rainwater, increasing the water flow space to ensure the water needed by plants.

[0050] The...

Embodiment 2

[0059] The present embodiment provides a construction method for the ecological protection structure of the broken rock steep slope described in Embodiment 1, specifically comprising the following steps:

[0060] S01. Cleaning and leveling the slope surface, mainly cleaning and leveling the slope surface for subsequent construction.

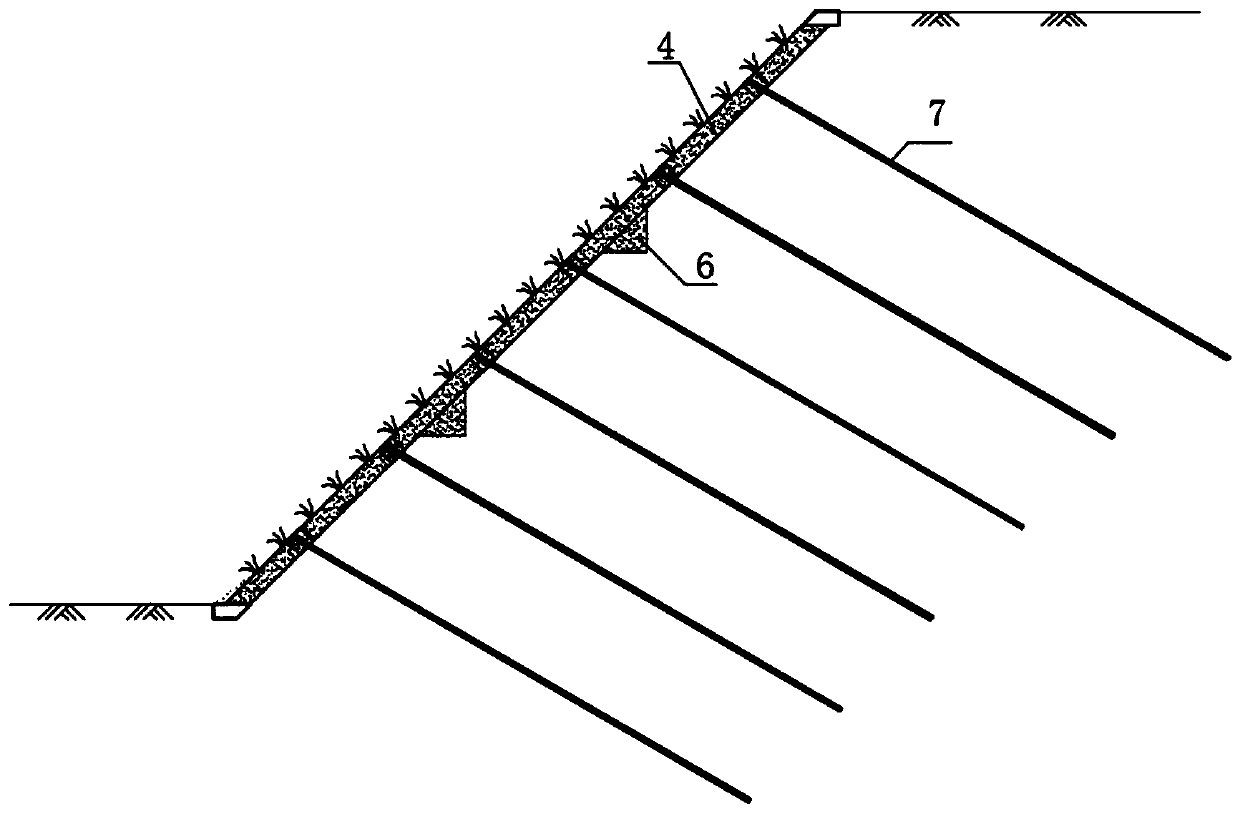

[0061] S02. Stakeout planning: according to the on-site stakeout of the construction drawings, determine the construction positions of the anchor rod 7 and the lattice beam 4.

[0062] S03, installation of anchor rod 7: according to the anchor rod 7 determined in step S02, locate, drill, install the anchor rod and fix it by grouting;

[0063] Wherein the construction method of anchor rod 7 specifically comprises the steps:

[0064] S031. Carry out dry drilling on the slope to drill holes, and use high-pressure air to clean (0.4MPa) to ensure good consolidation of mortar and hole walls;

[0065] S032. Filling cement mortar, the grouting pipe and...

Embodiment 3

[0080] In the step S05 of Embodiment 1 and Embodiment 2, the lattice beam 4 that needs to be formed and solidified is a porous structure, so this embodiment provides a concrete manufacturing method for forming a porous lattice beam 4, which specifically includes the following steps:

[0081] S051: In parts by weight, prepare the following raw materials: 10-13 parts of water, 34-37 parts of cement, 135-145 parts of gravel aggregate, 0.6-1.1 parts of polycarboxylate superplasticizer, 1.4- 2 parts of strengthening agent, 2-2.5 parts of mineral admixture.

[0082] In step S051:

[0083] Mineral admixture can use silica fume;

[0084] The cement is made of ordinary Portland cement with strength grade 42.5; the technical performance index of the cement is qualified, and the stability is qualified;

[0085] The crushed stone aggregate particle size is 5-10mm, the gradation is uniform, the apparent density is 2500-2800kg / m3, the close packing density is 1400-1500kg / m3, and does not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com