A buoyancy-driven photovoltaic panel pre-spray cooling system and cooling method

A buoyancy drive and cooling system technology, applied in photovoltaic modules, photovoltaic power generation, lighting and heating equipment, etc., can solve the problems of limited air-cooling lifting effect, large water consumption, complex system and other problems, and achieve low harm such as photovoltaic panel corrosion, Uniform cooling effect and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

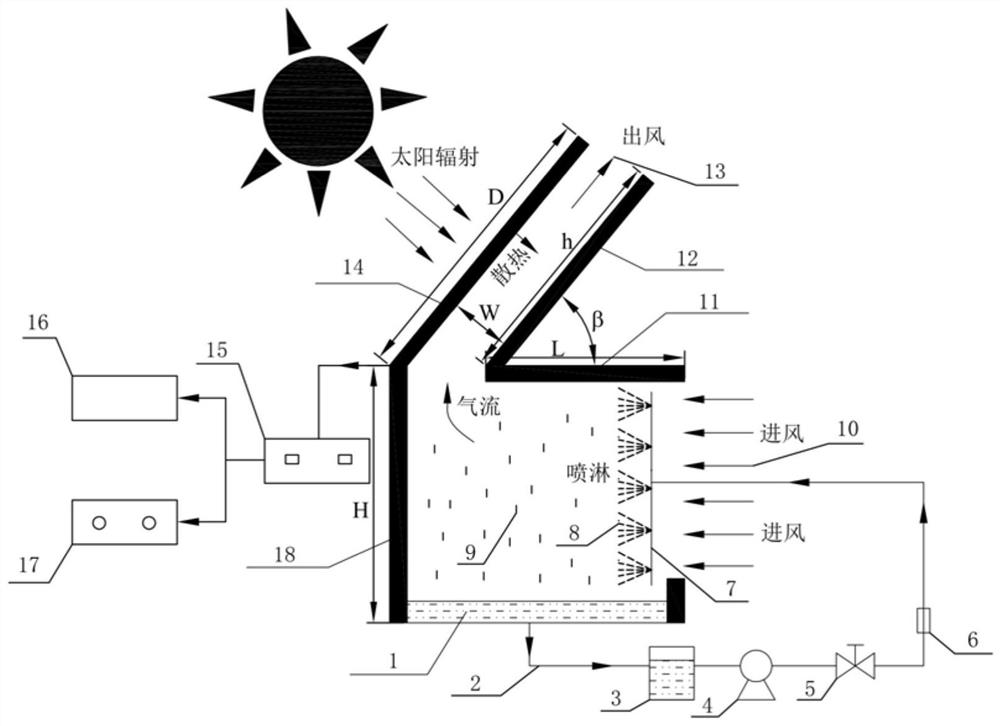

[0049] Such as figure 1 As shown, the buoyancy-driven photovoltaic panel pre-spray cooling system mainly includes a pre-spray water system, an airflow channel system, and a photovoltaic power generation system.

[0050] The pre-spray water system includes a sump 1 , a water return pipe 2 , a water storage tank 3 , a water pump 4 , a control valve 5 , a flow meter 6 , a water distributor 7 and a nozzle 8 connected in sequence. There are multiple nozzles 8 distributed on the water distributor 7 . The water collected in the sump is pumped to the nozzles for pre-spraying by the water pump 4.

[0051] The air flow passage system mainly includes an air inlet 10, a deflector 11, an inclined plate 12, an air outlet 13, a photovoltaic panel 14 and a support plate 18, and the support plate 18 encloses an air inlet chamber, and the side of the air inlet chamber is opened to form an air inlet chamber. The tuyere 10 and the deflector 11 are located at the top of the air inlet chamber. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com