Installation and adjustment method of wide-spectrum high-resolution echelle grating monochromator

A step grating and adjustment method technology, which is applied in the field of spectroscopy, can solve the problems of cumbersome installation and adjustment process and large dependence on the experience of the installer, and achieve less professional auxiliary equipment, less time-consuming installation and adjustment, and lower installation and adjustment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

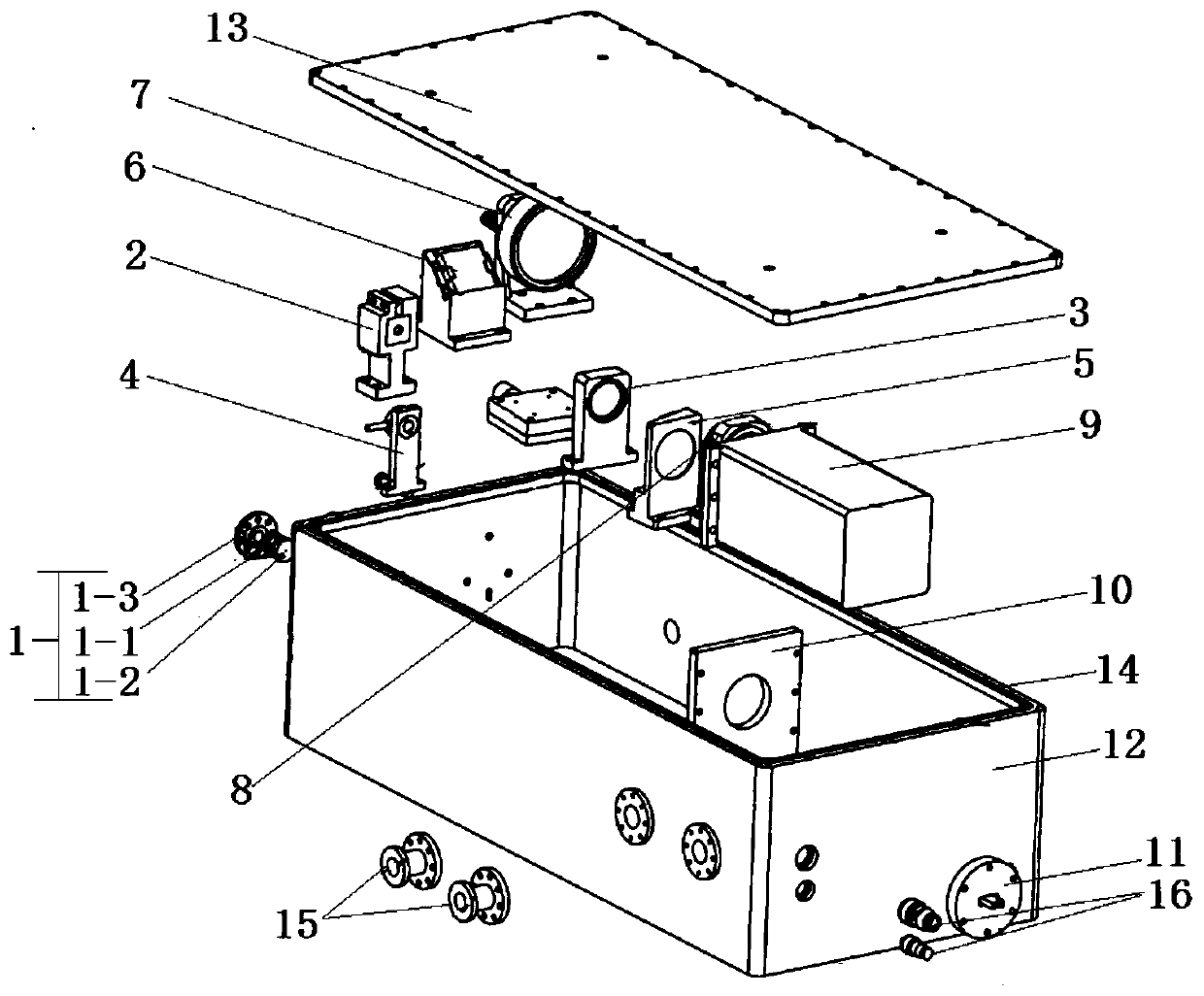

[0024] The following will be combined with figure 1 with attached figure 2 Specific embodiments of the present invention will be described in detail.

[0025] A method for installing and adjusting a wide-spectrum high-resolution echelle grating monochromator: the method includes the following steps:

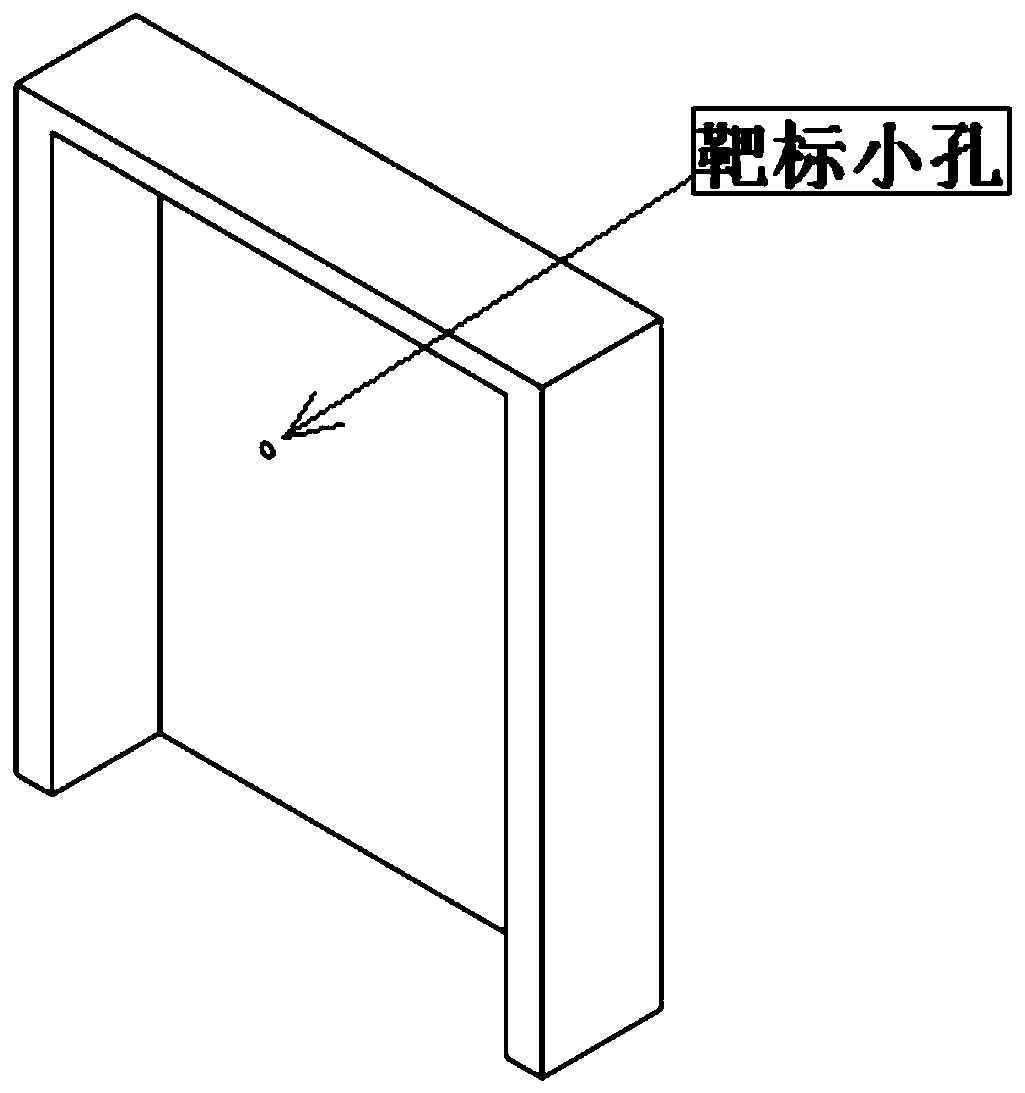

[0026] Step S1: Install the pinhole assembly 1 at the designed position on the mechanical housing 12, the pinhole assembly 1 includes a vacuum sealing ring 1-1 interconnected with the mechanical housing 12, and a calcium fluoride needle tightly connected in the vacuum sealing ring 11 Holes 1-2 and the star-point hole pressure plate 1-3 that closely fits the calcium fluoride pinhole 1-2, and the star-point hole pressure plate 1-3 is fixed on the mechanical On the casing 12, when tightening, the diagonal screws should be tightened first, and the force should be uniform to ensure the stability of the calcium fluoride pinhole 12;

[0027] Step S2: Use the laser as the debugging l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com