Janus nitrogen-doped carbon nanofiber film as well as preparation method and application thereof

A technology of carbon nanofibers and nanofibers, applied in the field of Janus nitrogen-doped carbon nanofiber films and their preparation and application, can solve the problems of unfavorable Janus film low-cost preparation, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In view of the shortcomings of the existing Janus film preparation methods such as cumbersome preparation process and the use of toxic or highly corrosive chemicals, the present invention proposes a Janus nitrogen-doped carbon nanofiber film and its preparation method and application.

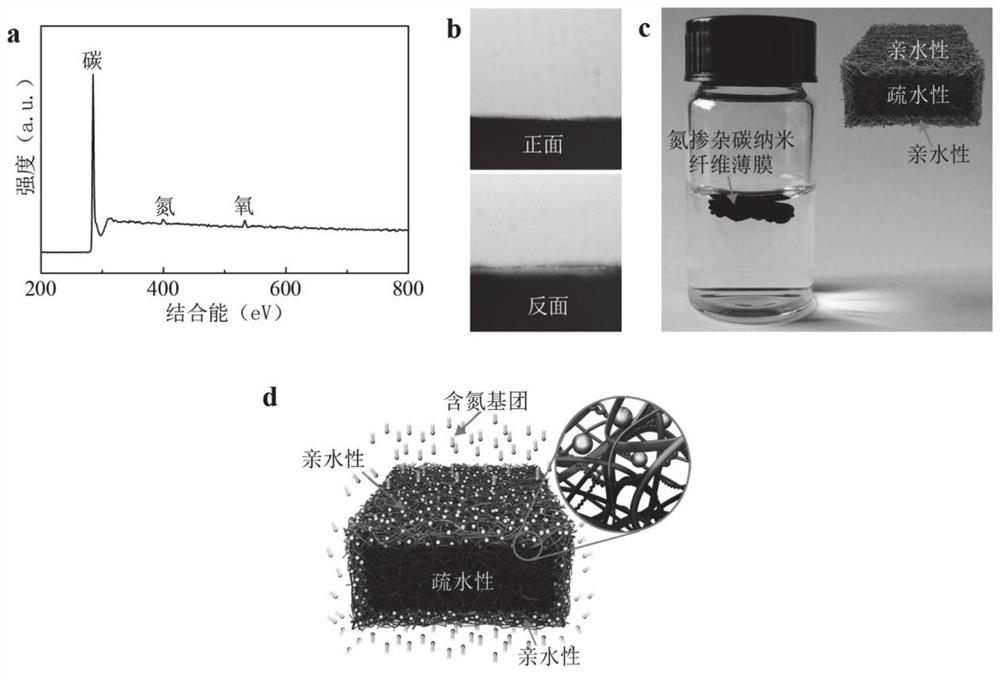

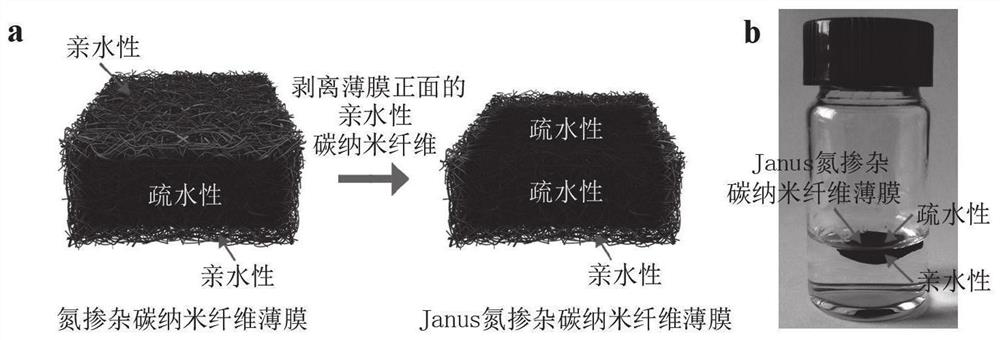

[0023] A typical embodiment of the present invention provides a method for preparing Janus nitrogen-doped carbon nanofiber film. In an inert atmosphere, the mixed gas of ammonia and inert gas is passed into the carbon nanofiber film, and heated to 850 ~ Treat at 950° C. for 3 to 15 minutes to obtain a nitrogen-doped carbon nanofiber film; remove the nitrogen-doped layer on one side of the nitrogen-doped carbon nanofiber film to obtain a Janus nitrogen-doped carbon nanofiber film.

[0024] It was found through experiments that the carbon nanofiber film treated with ammonia gas can change from hydrophobicity to hydrophilicity. The ammonia treatment time affects the extent to which the carb...

Embodiment 1

[0040] (1) Preparation of carbon nanofiber film:

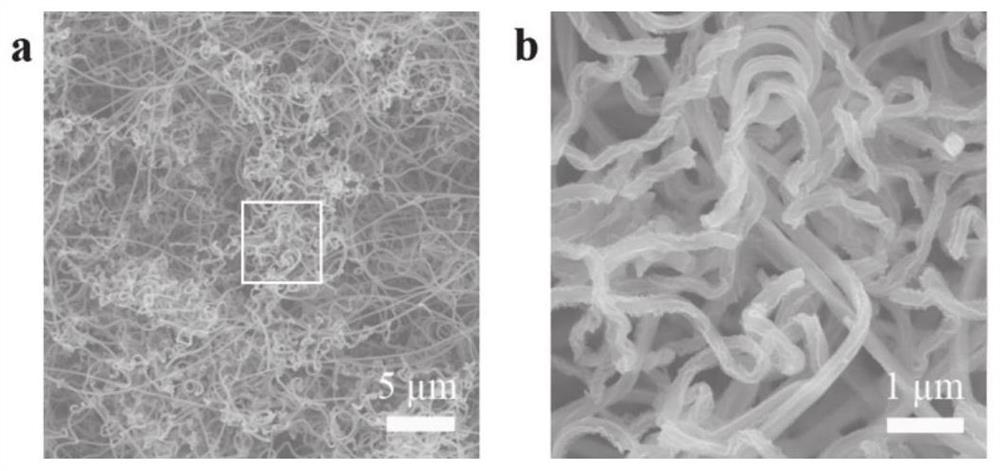

[0041] First, place the aluminum sheet in 0.1M copper nitrate aqueous solution, take it out and dry it, and then place it on the bottom of the ceramic boat. Then, place the ceramic boat in the quartz tube of the horizontal tube-type resistance furnace, first pass argon into the quartz tube, and then pass acetylene (0.06 liters per minute) and argon into the quartz tube when the furnace temperature rises to 440°C The mixed gas of gas (0.006 L / min) is about 60h. After the reaction is over, a carbon nanofiber film will grow on the surface of the aluminum sheet. Finally, peel off the carbon nanofiber film from the surface of the aluminum sheet to obtain an independent carbon nanofiber film. The electron microscope picture of the carbon nanofiber film is as follows: figure 1 shown in a and b.

[0042] (2) Preparation of nitrogen-doped carbon nanofiber film:

[0043] Place the carbon nanofiber film on the bottom of the ceramic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com