Winding process for lithium battery separator

A lithium battery separator and process technology, applied in the field of lithium battery separator preparation, can solve problems such as tension control failure, wavy edges generated by separator winding, and uneven stretching, so as to reduce defective products, realize large-scale production and operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

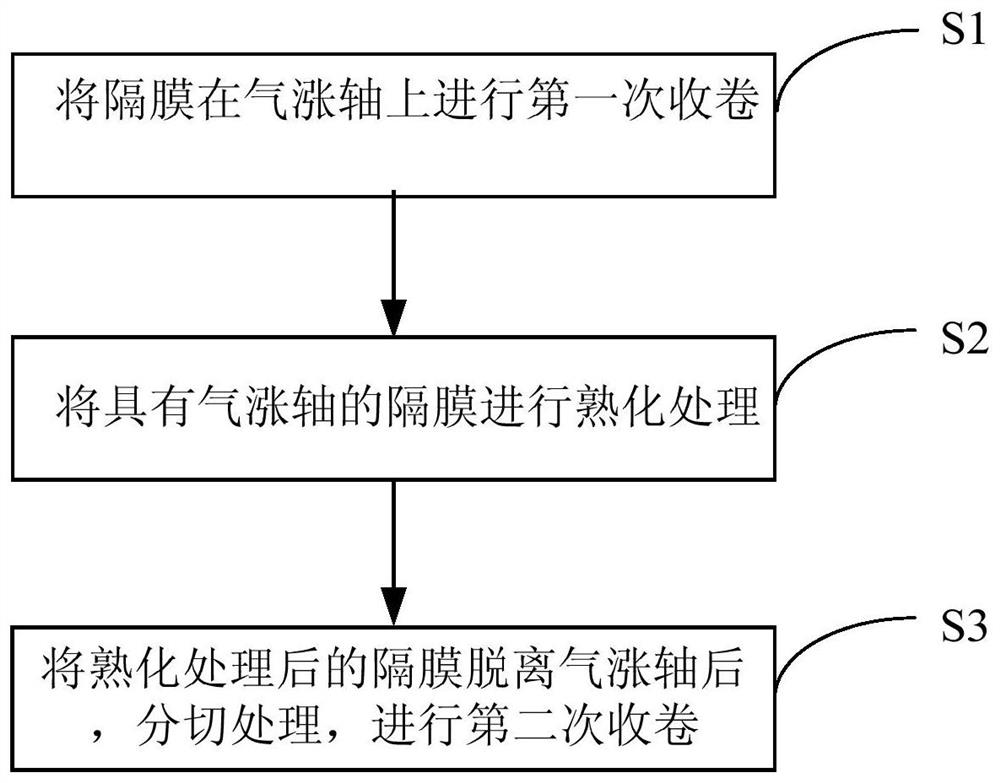

Method used

Image

Examples

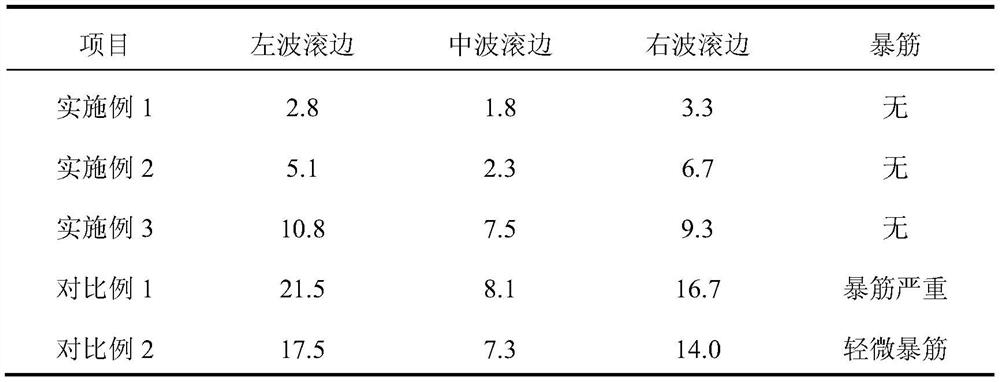

Embodiment 1

[0040] S1. Cover the outer surface of the air expansion shaft with an outer diameter of 178mm with a layer of cushion cotton with a hardness of 45HA, and perform the first winding on the air expansion shaft with a width of 1200mm diaphragm covering the buffer cotton, and the first winding The tension is 4N, and the first winding speed is 80m / min;

[0041] S2. Put the diaphragm with the air expansion shaft in step S1 into the curing room for curing treatment. The curing treatment adopts the suction of the air expansion shaft to reduce the outer diameter of the air expansion shaft to 8mm and place it at a temperature of 43°C , The storage time is 13h for maturation;

[0042] S3. After separating the cured diaphragm from the air expansion shaft, perform a slitting process, and perform a second winding of the diaphragm with a width of 1100 mm.

Embodiment 2

[0044] S1. Cover the outer surface of the air expansion shaft with an outer diameter of 176mm with a layer of cushion cotton with a hardness of 43HA, and perform the first winding on the air expansion shaft with a width of 1100mm diaphragm covering the buffer cotton, and the first winding The tension is 4N, and the first winding speed is 70m / min;

[0045] S2. Put the diaphragm with the air expansion shaft in step S1 into the curing room for curing treatment. The curing treatment adopts the suction of the air expansion shaft to reduce the outer diameter of the air expansion shaft to 6mm and place it at a temperature of 43°C , The storage time is 12h for maturation;

[0046] S3. After separating the cured diaphragm from the air expansion shaft, perform a slitting process, and perform a second winding of the diaphragm with a width of 1000 mm.

Embodiment 3

[0048] S1. Cover the outer surface of the air expansion shaft with an outer diameter of 176mm with a layer of cushion cotton with a hardness of 43HA, and perform the first winding on the air expansion shaft with a width of 1100mm diaphragm covering the buffer cotton, and the first winding The tension is 5N, and the first winding speed is 90m / min;

[0049] S2. Put the diaphragm with the air expansion shaft in step S1 into the curing room for curing treatment. The curing treatment adopts the suction of the air expansion shaft to reduce the outer diameter of the air expansion shaft to 6mm and place it at a temperature of 41℃ , The time is 24h for maturation;

[0050] S3. After separating the cured diaphragm from the air expansion shaft, perform a slitting process, and perform a second winding of the diaphragm with a width of 1000 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com