Monocrystalline silicon wafer cleaning method

A single crystal silicon wafer, silicon wafer technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problem that the cleaning process cannot be applied to single crystal silicon wafer cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

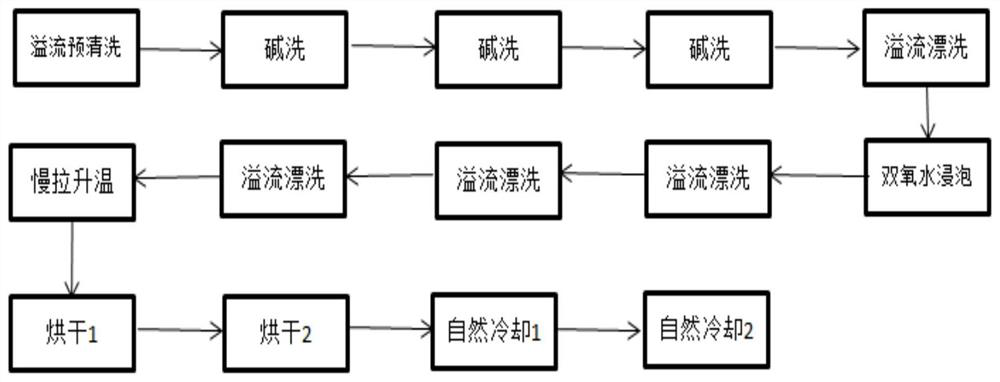

[0020] Such as figure 1 As shown, the monocrystalline silicon wafer cleaning method of the present invention sequentially includes the steps of overflow pre-cleaning, alkali cleaning, primary overflow rinsing, hydrogen peroxide soaking, secondary overflow rinsing, slow heating, drying, and natural cooling at room temperature, specifically as follows:

[0021] Overflow pre-cleaning: The overflow speed of single crystal is required to be 220L / Hour. The function is to pre-clean the surface of the silicon wafer after degumming, and simply remove large impurities on the surface of the silicon wafer such as glue, degumming agent, and lactic acid;

[0022] Alkali cleaning: Use solid alkali (purified grade KOH), surfactant, and pure water to prepare an alkaline cleaning mixed solution (KOH) with a concentration of 3%, and use three ultrasonic alkaline cleaning tanks to clean the silicon wafers in sequence. 50°C;

[0023] One overflow rinse: overflow speed 300L / Hour. The function is...

Embodiment 2

[0030] The cleaning method of monocrystalline silicon wafers includes pre-cleaning, alkaline cleaning, primary overflow rinsing, hydrogen peroxide immersion, secondary overflow rinsing, slow heating, drying, and natural cooling at room temperature. The details are as follows:

[0031] Overflow pre-cleaning: The overflow speed of single crystal is required to be 250L / Hour. The function is to pre-clean the surface of the silicon wafer after degumming, and simply remove residual substances such as glue, degumming agent, lactic acid, etc.;

[0032] Alkali cleaning: Use solid alkali (purified grade KOH), surfactant, and pure water to prepare an alkaline cleaning mixed solution (KOH) with a concentration of 4%, and use three ultrasonic alkaline cleaning tanks to clean the silicon wafers in sequence. 55°C;

[0033] One-time overflow rinsing: the overflow speed is 210L / Hour. The function is to rinse the mixed solution (KOH / surfactant) after alkali washing to reduce the chemical resid...

Embodiment 3

[0040] The cleaning method of monocrystalline silicon wafers includes pre-cleaning, alkaline cleaning, primary overflow rinsing, hydrogen peroxide immersion, secondary overflow rinsing, slow heating, drying, and natural cooling at room temperature. The details are as follows:

[0041] Overflow pre-cleaning: the overflow speed of single crystal is required to be 230L / Hour. The function is to pre-clean the surface of the silicon wafer after degumming, and simply remove residual substances such as glue, degumming agent, lactic acid, etc.;

[0042] Alkali cleaning: Use solid alkali (purified grade KOH), surfactant, and pure water to prepare an alkaline cleaning mixed solution (KOH) with a concentration of 5%, and use multiple ultrasonic alkaline cleaning tanks to clean the silicon wafers in sequence. The temperature requirement is at 60°C;

[0043] One-time overflow rinsing: the overflow speed is 350L / Hour. The function is to rinse the mixed solution (KOH / surfactant) after alkali...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap