Auxiliary agent for fluorosulfonic acid aqueous solution and flusulfamic acid aqueous solution prepared from auxiliary agent

The technology of fluorosulfonic acid water preparation and auxiliary agent, which is applied in the field of pesticides, can solve the problems of poor efficacy and difficult to fully absorb the medicinal liquid, and achieve the effects of reducing the speed of drug resistance, facilitating industrial production and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] According to the method for preparing fluorosulfonate water agent according to the present invention, the method comprises the following steps: (1) preparing phytoamine polyoxyethylene ether amine oxide; (2) oxidizing the above-mentioned phytoamine polyoxyethylene ether Mix amine with polyglyceryl ether, cocamidopropyl amine oxide, alkyl glycoside and water into the reaction kettle, stir evenly to obtain additives; (3) Mix and add fomesafen technical, sodium hydroxide and water React in the reaction kettle until the material is uniform and transparent, then add the additives obtained above, and stir evenly to obtain the fluorosulfonate aqueous solution.

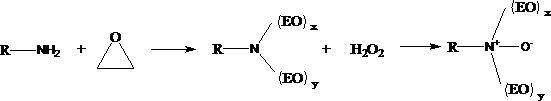

[0030] The reaction process of phytoamine polyoxyethylene ether amine oxide in the above step (1) is: add phytoamine to the polymerization reactor, feed ethylene oxide, add alkali catalyst, and polymerize at 130°C for 2 hours to obtain the intermediate plant Amine ether: Add phytoamine ether into the reaction kettle, s...

Embodiment 1

[0037] Preparation of cocoamine polyoxyethylene ether amine oxide: Add 193 parts of cocoamine into the polymerization reactor, feed 660 parts of ethylene oxide, then add an alkali catalyst, and polymerize for 2 hours at 130°C to obtain the intermediate coconut oil Amine ether: Add cocoamine ether into the reaction kettle, slowly add 895 parts of hydrogen peroxide (50% content) in batches, and stir and react at 40°C for 6 hours to obtain cocoamine polyoxyethylene ether amine oxide (15EO).

[0038] Preparation of auxiliary agents: Take 10 parts of polyglyceryl ether, 30 parts of cocoamine polyoxyethylene ether amine oxide (15EO), 20 parts of cocoamidopropyl amine oxide, 10 parts of alkyl glycoside and 30 parts of water into the reaction kettle, Stir evenly at 50°C to obtain additives.

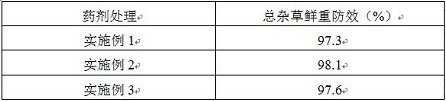

[0039] Preparation of 250g / L fluorosulfonate liquid: Add 23.5 parts of fomesafen technical (98% content), 2.5 parts of sodium hydroxide and 64 parts of water into the reaction kettle, react at 50...

Embodiment 2

[0041] Preparation of laurylamine polyoxyethylene ether amine oxide: add 183 parts of laurylamine into the polymerization reactor, pass through 880 parts of ethylene oxide, then add an alkali catalyst, and polymerize at 130°C for 2 hours to obtain the intermediate laurylamine ether Add laurylamine ether into the reaction kettle, slowly add 1116 parts of hydrogen peroxide (50% content) in batches, and stir and react at 40°C for 6 hours to obtain laurylamine polyoxyethylene ether amine oxide (20EO).

[0042]Preparation of additives: Take 15 parts of polyglyceryl ether, 20 parts of laurylamine polyoxyethylene ether amine oxide (20EO), 15 parts of cocamidopropyl amine oxide, 15 parts of alkyl glucoside and 35 parts of water into the reaction kettle, 50 parts Stir evenly at ℃ to obtain additives.

[0043] Preparation of 250g / L fluorosulfonate liquid: Add 23.5 parts of fomesafen technical (98% content), 2.5 parts of sodium hydroxide and 64 parts of water into the reaction kettle, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com