Composition high in free amino acids and use as a raw material and complete feed for animal feeding

A technology of free amino acids and amino acids, applied in the field of animal feed raw materials and complete feeds, can solve the problems of amino acid denaturation, destruction, and high cost, and achieve the effect of easy digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] Example 1 - Hydrolyzate 1

[0142] Preparation of hydrolyzate 1

[0143] 4500 kg of poultry feathers were introduced into a 20000 liter reactor / hydrolysis tower. The first chemical hydrolysis step was carried out by adding 18000 liters of hydrochloric acid (24%), the hydrolysis was carried out at 72° C. for 4.5 hours. The resulting product was stored at ambient temperature for 48 hours (pause in between). Next, a second chemical hydrolysis was performed by heating at 107 °C for 6 hours without addition of acid. The resulting product was left to cool. Cystine and tyrosine were extracted by precipitation with sodium hydroxide at pH 4 to 5. The hydrolyzate is desalted by electrodialysis. 22000 kg of hydrolyzate 1 were obtained in liquid form.

Embodiment 2

[0144] Embodiment 2-hydrolyzate 2

[0145] Preparation of hydrolyzate 2

[0146] 1 kg of desalted hydrolyzate 1 was diluted with 19.2 kg of purified water and passed through a nanofiltration membrane calibrated at 100 to 250 Da at a flow rate of 400 L / h at a pressure of 20 bar. The collected retentate weighed 5.2 kg and the permeate weighed 14.55 kg. The incoming desalted hydrolyzate contained 93% free amino acids (ie 0.19 kg) and the outgoing permeate contained 99.06% free amino acids, ie 0.05 kg. Therefore, the yield of free amino acids was 26.4%.

Embodiment 3

[0147] Embodiment 3-hydrolyzate 3

[0148] Preparation of hydrolyzate 3

[0149] 1 kg of desalinated hydrolyzate 1 was diluted with 12.6 kg of purified water and passed through a nanofiltration membrane calibrated at 100 to 250 Da at a flow rate of 800 L / h at a pressure of 36 bar. The collected retentate weighed 5.2 kg and the permeate weighed 8.55 kg. The incoming desalted hydrolyzate contained 93% free amino acids (ie 0.19 kg) and the outgoing permeate contained 97.87% free amino acids, ie 0.04 kg. Therefore, the yield of free amino acids was 22.4%.

[0150] result

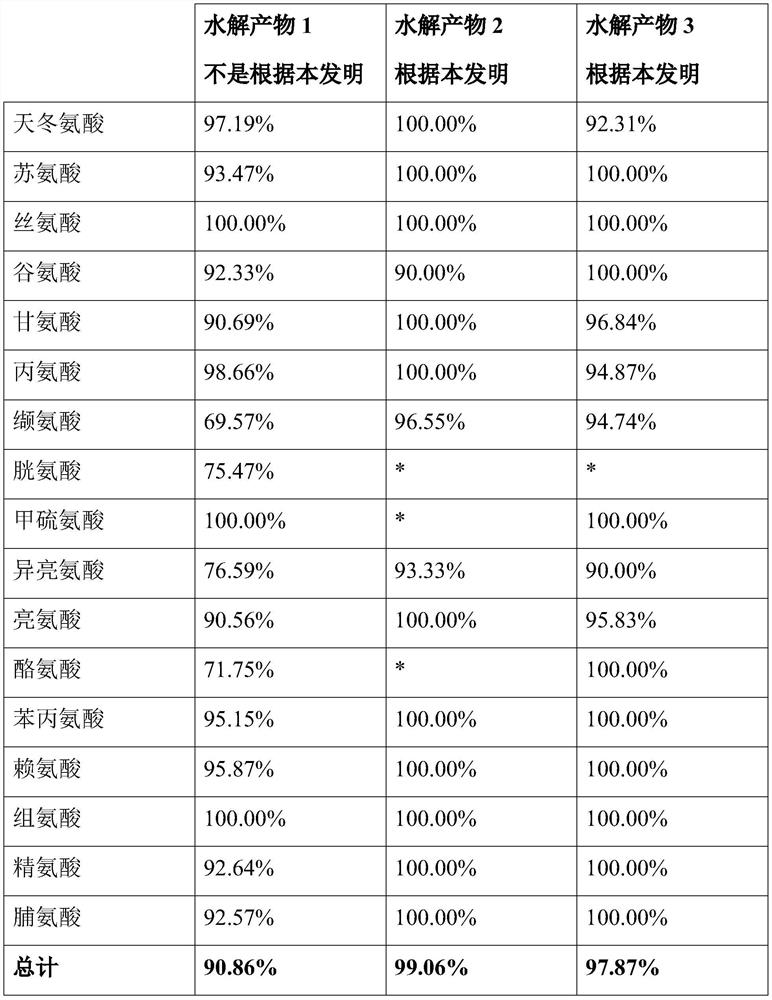

[0151] Table 1 shows the free amino acid / total amino acid weight fraction for each amino acid present.

[0152] [Table 1]

[0153]

[0154] *The percentage of amino acids in free form in the hydrolyzate is less than 0.002%.

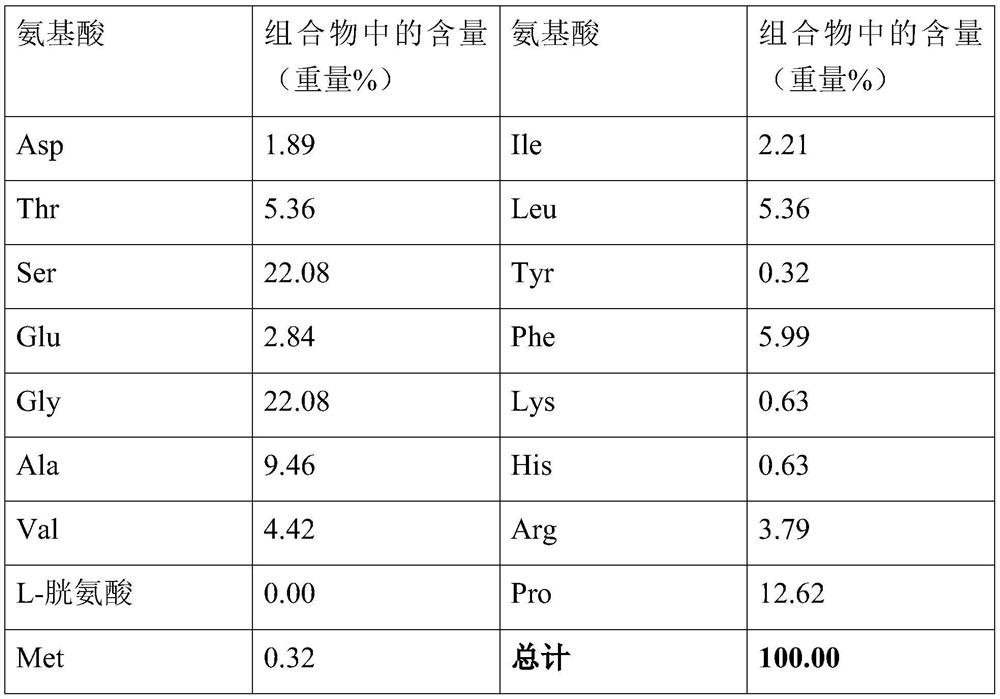

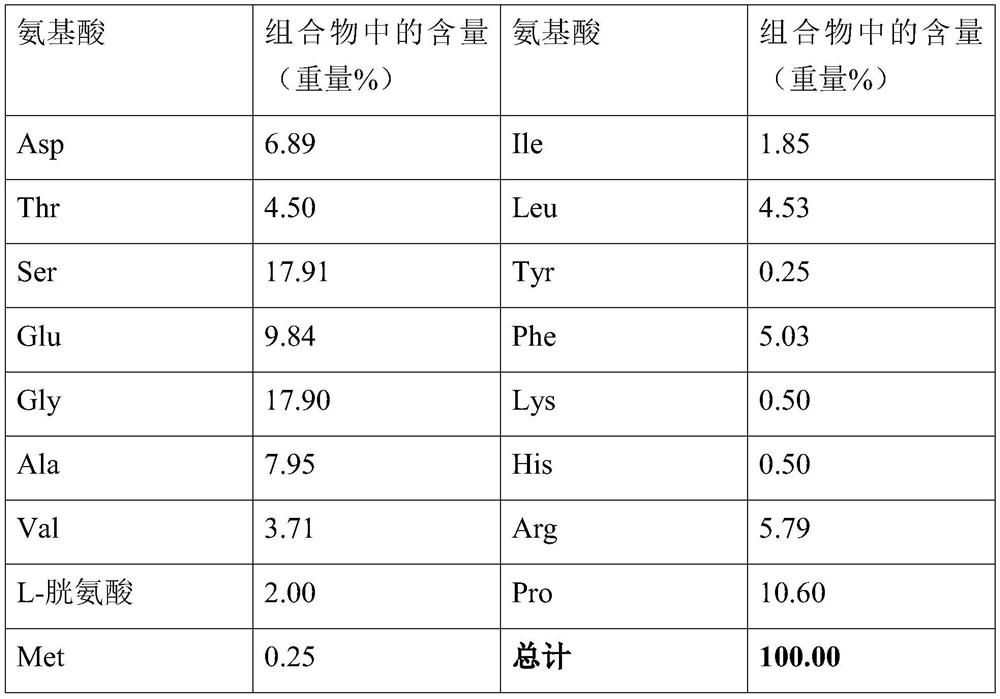

[0155] Determination of the composition of the hydrolyzate 2

[0156] The amino acid of hydrolyzate 2 was determined according to the method adapted and adjusted according to EC R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com