High-permeation-resistance epoxy powder coating production and processing device

A technology of epoxy powder and processing equipment, which is applied in the direction of powder coating, epoxy resin coating, feeding device, etc., can solve the problems of insufficient mixing and excessive thickness, and achieve the effect of improving the mixing effect and improving the full utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

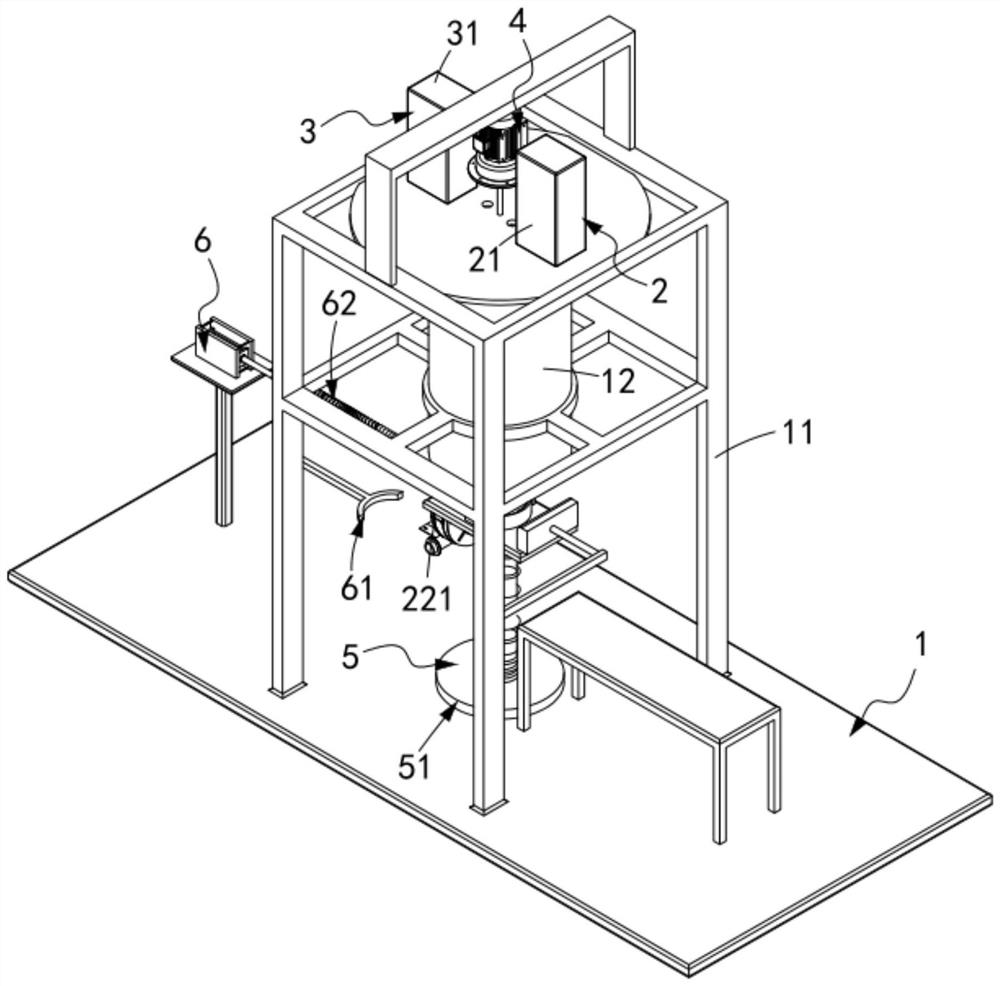

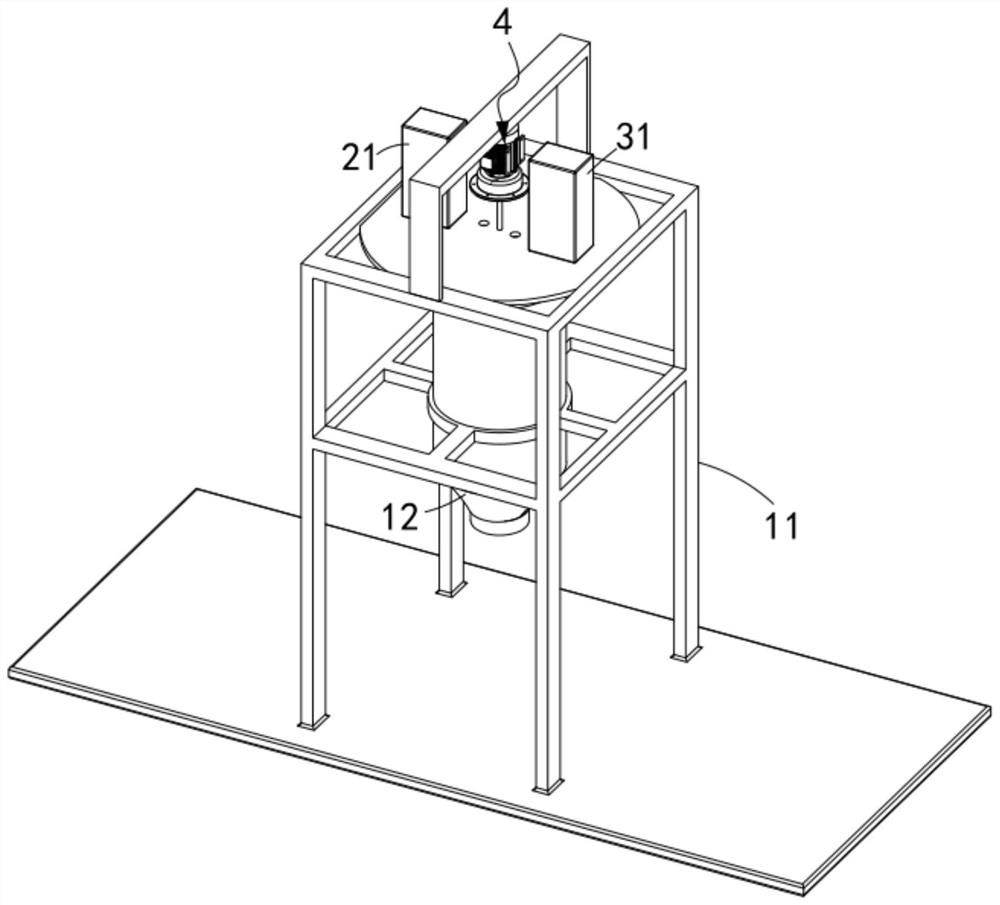

[0061] Such as figure 1 and Figure 4 Shown, a kind of high impermeability epoxy powder coating production processing device, comprises:

[0062] Supporting mechanism 1, described supporting mechanism 1 comprises frame 11 and the reactor 12 that is installed on described frame 11;

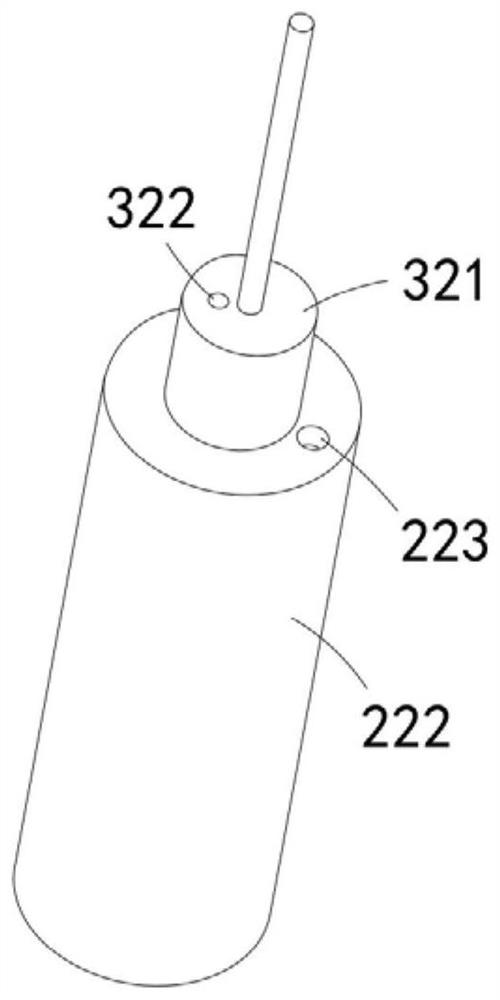

[0063] Material A conveying mechanism 2, the material A conveying mechanism 2 includes a first storage bin 21 installed on the frame 11 and a spreading material located in the reaction kettle 12 and communicated with the first storage bin 21 component 22;

[0064] B material conveying mechanism 3, said B material conveying mechanism 3 includes the second storage bin 31 installed on the frame 11 and the thinning assembly 32 built in the spreading assembly 22;

[0065] The driving mechanism 4, the driving mechanism 4 is installed on the frame 11 and is used to drive the spreading component 22 and the flinging component 32 to rotate along the circumference and be arranged in the reaction kettle 12;...

Embodiment 2

[0103] Such as Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0104] further, such as Figure 9 As shown, the lifting assembly 51 includes a base 511, a telescopic unit a512 that is vertically arranged and fixedly connected to the base 511 at one end, a receiving plate 513 fixedly connected to the other end of the telescopic unit a512, and installed on the The limiting seat 514 on the receiving plate 513 ; the holding dish 52 is matched and arranged in the limiting seat 514 .

[0105]In this embodiment, by setting the lifting assembly 51, the mixing material of the storage container 52 presses down on the telescopic unit a512 as the mass increases, and the telescopic unit a51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com