Emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and emulsifier, which is applied to building components, building insulation materials, buildings, etc., can solve problems such as damage to sticky layer materials, achieve the effect of improving construction efficiency and speeding up demulsification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

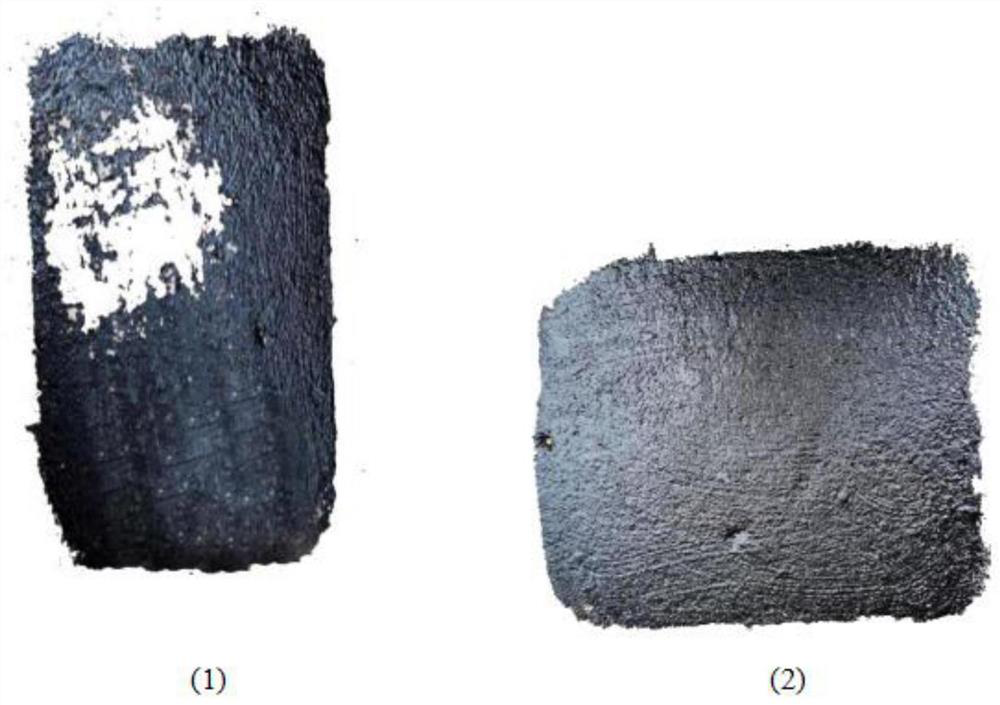

Image

Examples

Embodiment 1

[0026] Material selection: No. 70 GS petroleum pitch is used as the base pitch, the masterbatch produced by Hengli Petrochemical is used as the hard pitch, and the emulsifier is the quick-cracking and quick-setting emulsifier JY-R1W produced by Jiangsu Jinyang New Material Technology Co., Ltd., Shanghai Pu The styrene-butadiene rubber produced by Lang Rubber & Plastic Technology Co., Ltd. is used as the modifier, and the polyethylene wax emulsion produced by Dongguan Jianghai New Material Technology Co., Ltd. is used as the release agent. A 36% hydrogen chloride aqueous solution is selected as the emulsifier, and the molecular weight is 50000 carboxymethyl cellulose is used as a stabilizer. The above materials and water are weighed as follows.

[0027] No. 70 GS base asphalt 30kg Hard pitch 20kg JY-R1W 2.5kg Styrene butadiene rubber 2kg Polyethylene wax emulsion 0.2kg Carboxymethyl cellulose 0.05kg Hydrochloric acid and water (PH=3) 45.25kg

[0028] Dissolve 0.05kg of c...

Embodiment 2

[0032] Material selection: No. 70 Ssangyong petroleum asphalt is used as the base asphalt, the masterbatch produced by Hengli Petrochemical is used as the hard asphalt, and the emulsifier is the fast-cracking quick-setting emulsifier CK-60 produced by Tianlong Chemical Co., Ltd., produced by Ruipu Plastic Co., Ltd. The PE is the modifier, the polyethylene wax emulsion produced by Dongguan Jianghai New Material Technology Co., Ltd. is used as the release agent, the 36% hydrogen chloride aqueous solution is selected as the emulsifier, and calcium chloride is selected as the stabilizer. The above materials and water are weighed as follows.

[0033] No. 70 Ssangyong Base Asphalt 40kg Hard pitch 10kg CK-60 3.5kg PE 2kg Polyethylene wax emulsion 0.2kg Calcium chloride 0.1kg Hydrochloric acid and water (PH=3) 44.2kg

[0034] Dissolve 0.1kg of calcium chloride and 3.5kg of CK-60 emulsifier in 35kg of 50℃-70℃ warm water. After it is completely dissolved, adjust the pH to about 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com