PVC material with low density and high plasticity

A PVC material, high plasticity technology, applied in the application field of industrial slag, can solve the problems that affect the application of PVC materials, can not reduce environmental pollution, environmental hazards, etc., achieve excellent anti-aging performance, good plasticity, and reduce pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

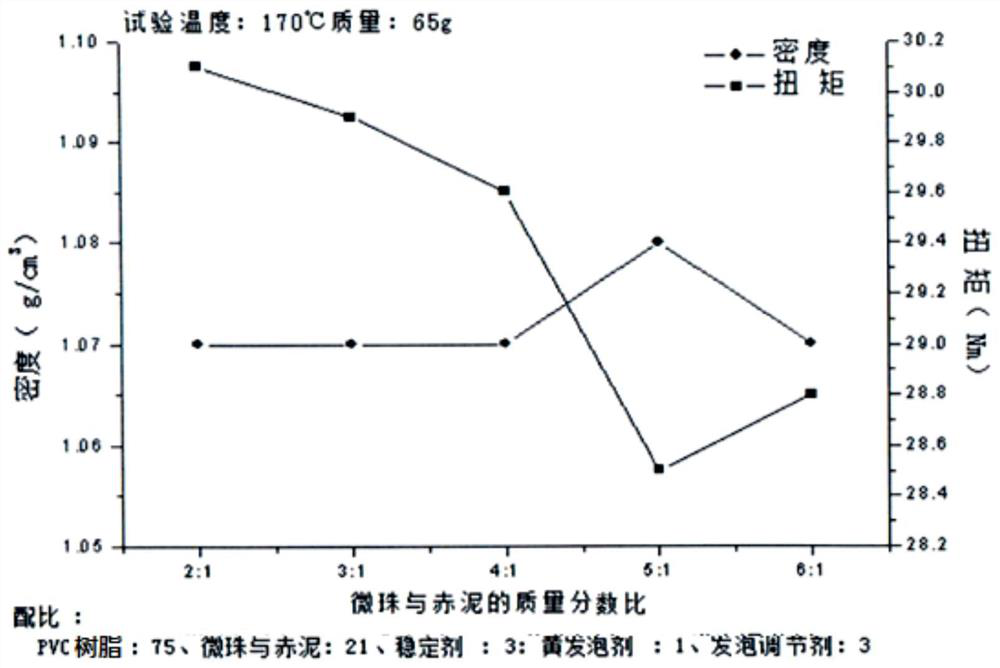

Image

Examples

Embodiment 1

[0016] Embodiment 1. A PVC material with low density and high plasticity of the present invention is prepared from the following raw materials in proportions by weight: 65-85 parts of PVC resin, 10-18 parts of red mud, and 5-9 parts of microbeads , 2-4 parts of stabilizer, 0.5-1.5 parts of yellow foaming agent, 2-4 parts of foam regulator, 0.2-0.5 parts of phthalic acid diester, 0.1-0.2 parts of di-n-butyl phthalate, 0.05-0.1 part of diisodecyl phthalate, 0.02-0.1 part of diisononyl phthalate.

Embodiment 2

[0017] Embodiment 2, as a more accurate proportion by weight: 70-80 parts of PVC resin, 12-16 parts of red mud, 6-8 parts of microbeads, 2.5-3.5 parts of stabilizer, 0.75-1.25 parts of yellow foaming agent , 2.5-3.5 parts of foam regulator, 0.3-0.4 parts of phthalic acid diester, 0.13-0.17 parts of di-n-butyl phthalate, 0.075-0.0.09 parts of diisodecyl phthalate, ortho 0.05-0.07 parts of diisononyl phthalate.

Embodiment 3

[0018] Example 3, the specific weight ratio is: 75 parts of PVC resin, 14 parts of red mud, 7 parts of microbeads, 3 parts of stabilizer, 1.0 parts of yellow foaming agent, 3 parts of foam regulator, phthalic acid 0.35 part of diester, 0.15 part of di-n-butyl phthalate, 0.08 part of diisodecyl phthalate, and 0.06 part of diisononyl phthalate.

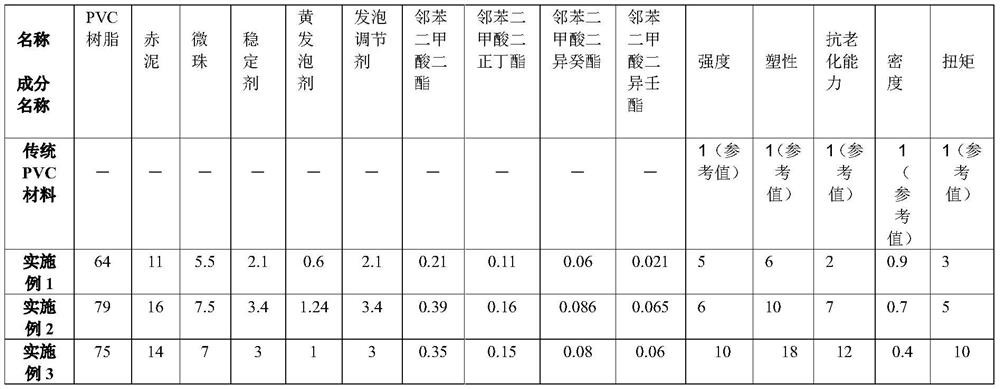

[0019] Through the correlation performance of traditional PVC material, embodiment 1, embodiment 2 and embodiment 3, the experimental comparison is made, and the relevant data are as shown in table 1:

[0020]

[0021] It can be seen from the relevant data in Table 1 that when taking 75 parts of PVC resin, 14 parts of red mud, 7 parts of microbeads, 3 parts of stabilizer, 1.0 parts of yellow foaming agent, 3 parts of foaming regulator, phthalic acid When 0.35 parts of diester, 0.15 parts of di-n-butyl phthalate, 0.08 parts of diisodecyl phthalate, and 0.06 parts of diisononyl phthalate, the PVC material obtained has the highest stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com