Water-controlling and scale-inhibiting coated proppant and preparation method thereof

A technology of proppant and water control agent, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., which can solve the problems of easy to be flattened, low long-term conductivity of filled cracks, and the function of film-coated proppant A single problem, to achieve the effect of reducing the degree of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

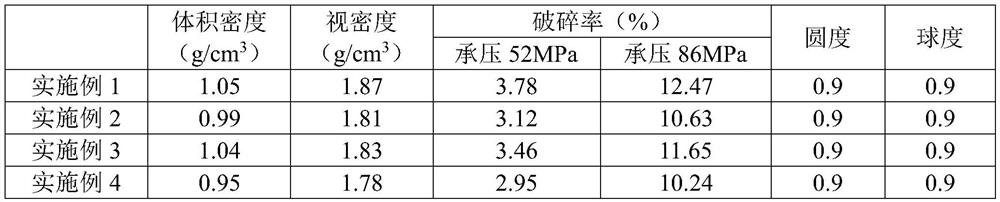

Examples

Embodiment 1

[0029] The preparation process of a film-coated proppant for controlling water and scaling is as follows:

[0030] (1) Weigh 30 / 50 purpose porous proppant (bulk density 1.15g / cm 3 , apparent density 2.07g / cm 3 ) 2100g, phenolic resin 360g, triethylenetetramine 120g, dibutyl phthalate 120g, vinyl chloropropyl triethoxysilane 180g, aminotrimethylene phosphonic acid 60g, polyacrylamide 60g;

[0031] (2) dissolving aminotrimethylene phosphonic acid in water to form a solution, soaking a 30 / 50 mesh porous proppant therein for 36 hours and then drying;

[0032] (3) Polyacrylamide is dissolved in 420g of absolute ethanol to form a pore-forming solution;

[0033] (4) Heat the phenolic resin to a molten state at 250° C., add triethylenetetramine, dibutyl phthalate, and vinyl chloride propyl triethoxysilane, and stir evenly to form a resin mixture;

[0034] (5) The porous proppant after drying is blown into the fluidized bed by air to form a fluidized bed;

[0035] (5) Spray the por...

Embodiment 2

[0038] The preparation process of a film-coated proppant for controlling water and scaling is as follows:

[0039] (1) Weigh 30 / 50 purpose porous proppant (bulk density 1.15g / cm 3 , apparent density 2.07g / cm 3 ) 1860g, phenolic resin 450g, triethylenetetramine 150g, dibutyl phthalate 150g, vinyl chloropropyl triethoxysilane 210g, aminotrimethylene phosphonic acid 90g, polyacrylamide 90g;

[0040] (2) dissolving aminotrimethylene phosphonic acid in water to form a solution, soaking a 30 / 50 mesh porous proppant therein for 36 hours and then drying;

[0041] (3) Polyacrylamide is dissolved in 630g of absolute ethanol to form a pore-forming solution;

[0042] (4) Heat the phenolic resin to a molten state at 250° C., add triethylenetetramine, dibutyl phthalate, and vinyl chloride propyl triethoxysilane, and stir evenly to form a resin mixture;

[0043] (5) The porous proppant after drying is blown into the fluidized bed by air to form a fluidized bed;

[0044] (5) Spray the por...

Embodiment 3

[0047] The preparation process of a film-coated proppant for controlling water and scaling is as follows:

[0048] (1) Weigh 30 / 50 purpose porous proppant (bulk density 1.15g / cm 3 , apparent density 2.07g / cm 3 ) 2100g, epoxy resin 360g, tetraethylenepentamine 120g, dimethyl phthalate 120g, aminopropylmethyldimethoxysilane 180g, diethylenetriaminepentamethylenephosphonic acid 60g, polyepoxy Ethane 60g;

[0049] (2) Diethylenetriaminepentamethylenephosphonic acid is dissolved in water to form a solution, and a 30 / 50 mesh porous proppant is soaked in it for 36h and then dried;

[0050] (3) dissolving polyethylene oxide in 420g absolute ethanol to form a pore-forming solution;

[0051] (4) Heat the phenolic resin to a molten state at 250° C., add tetraethylenepentamine, dimethyl phthalate, and aminopropylmethyldimethoxysilane, and stir to form a resin mixture;

[0052] (5) The porous proppant after drying is blown into the fluidized bed by air to form a fluidized bed;

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com