Pneumatic cast iron pipe centrifugal casting machine mold braking device

A centrifugal casting machine, braking device technology, applied in drum brakes, brake types, brake actuators, etc., can solve the problem of reducing the service life of equipment and molds, the hidden dangers of the stability of the operation effect of the electromagnetic brake mechanism, and the shaft It can improve the operation efficiency and stability, the action mechanism is efficient and reliable, and the service life is prolonged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

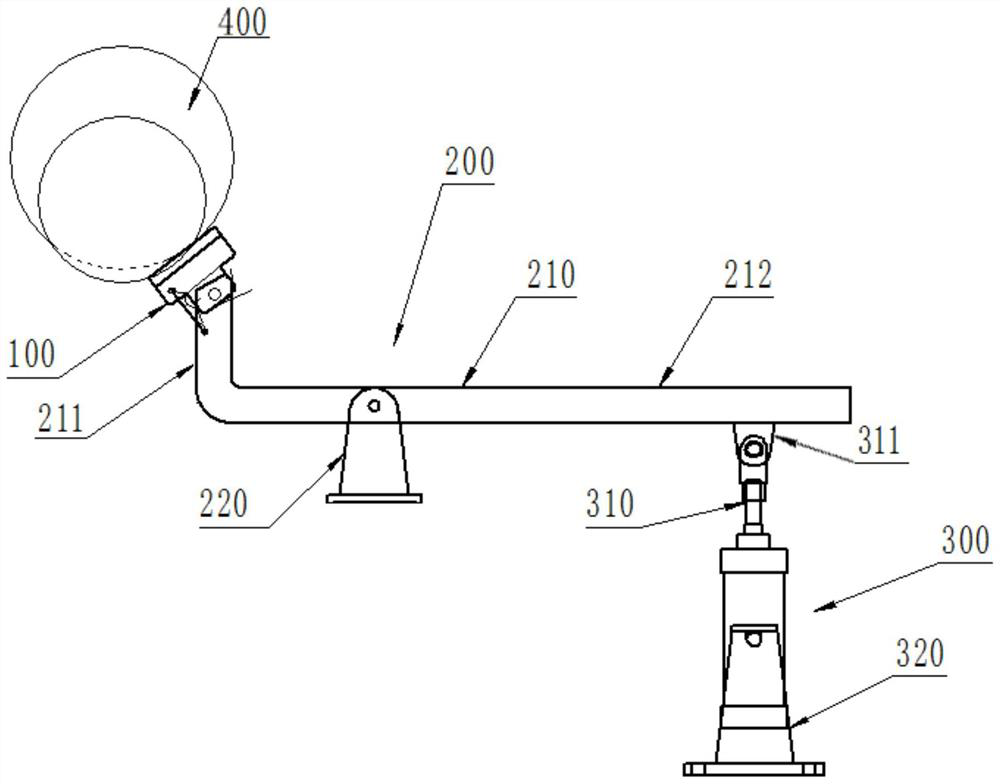

[0023] Such as figure 1 As shown, a pneumatic cast iron pipe centrifugal casting machine mold brake device includes a brake metal block 100 for directly acting on the outer surface of the cast pipe mold 400 to brake it, a brake transmission part 200 and a brake Power part 300, one end of the brake transmission part 200 is connected to the brake metal block 100, and the other end is connected to the brake power part 300; the brake metal block 100 is in contact with the outer surface of the cast pipe mold 400 Direct contact and friction reduce the dedicated speed of the cast pipe mold 400. The braking transmission part 200 acts as a force transmission during the braking action, and the braking power part 300 is used to provide power for the braking action of the mold 400. ;

[0024] The brake transmission part 200 includes a transmission lever 210 and a lever support 220, the transmission lever 210 is installed on the lever support 220 through a pin shaft, and the "pin shaft" s...

Embodiment 2

[0029] Based on the structure of Embodiment 1, in Embodiment 2, the length direction of the horizontal rod 212 of the transmission lever 210 and the length direction of the vertical rod 211 form a 90° right angle, and the length of the horizontal rod 212 is greater than The length dimension of the vertical rod 211.

Embodiment 3

[0031] Based on the structure of Embodiment 1, in Embodiment 3, the distance between the trunnion cylinder 310 and the lever support 220 is much greater than the distance between the brake metal block 100 and the lever support 220, which can reduce the The force to be borne by the trunnion cylinder 310 during braking.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap