A method and device for non-destructive testing of aluminum alloy residual stress

A technology of residual stress and non-destructive testing, applied in the direction of force/torque/work measuring instruments, measuring devices, instruments, etc., can solve problems such as difficult to meet high standards, impact, etc., to improve accuracy and repeatability, detection High sensitivity, excellent accuracy and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

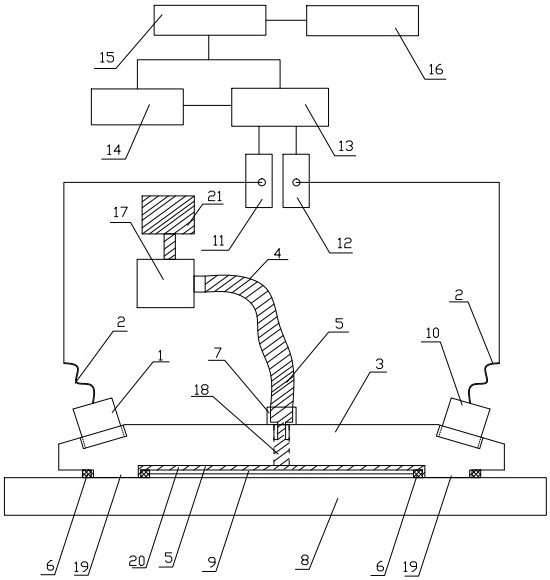

Image

Examples

Embodiment 1

[0044]This preferred embodiment provides a method for non-destructive detection of aluminum alloy residual stress, comprising the following steps:

[0045] S1. Prepare nearly zero residual stress samples parallel to the main deformation direction A of the aluminum alloy, a total of 20 groups, named A 0 , A 1 , A 2 , A 3 ,...,A 18 , A 19 ; The number of samples in each group is 5 parallel samples, and the final result is the arithmetic mean of the test results of parallel samples. The shape of the sample is dumbbell-shaped, the thickness of the sample is 20mm, the total length is 240mm, and the radius of the transition arc is 40mm; the near-zero residual stress sample is first subjected to vibration aging method, and then the method of stress relief annealing is used to reduce the residual stress.

[0046] S2, preparing samples in different annealing states, the near-zero residual stress sample A prepared in step S1 0 , A 1 , A 2 , A 3 ,...,A 18 , A 19 Annealing acco...

Embodiment 2

[0065] This preferred embodiment provides a method for non-destructive detection of aluminum alloy residual stress, comprising the following steps:

[0066] S1. Preparation of near-zero residual stress samples parallel to the main deformation direction A of the aluminum alloy, a total of 16 groups, named A 0 , A 1 , A 2 , A 3 ,...,A 14 , A 15 ; The number of samples in each group is 5 parallel samples, and the final result is the arithmetic mean of the test results of parallel samples. The shape of the sample is dumbbell-shaped, the thickness of the sample is 25mm, the total length is 250mm, and the radius of the transition arc is 45mm; the near-zero residual stress sample is first mechanically stretched to reduce the residual stress, and then the high-energy ultrasonic beam is used to reduce the residual stress.

[0067] S2, preparing samples in different annealing states, the near-zero residual stress sample A prepared in step S1 0 , A 1 , A 2 , A 3 ,...,A 14 , A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com