A chip resistor

A chip resistor and resistor technology, applied in resistors, resistor terminals/electrodes, non-adjustable metal resistors, etc., can solve the short-circuit failure at both ends of the chip resistor, it is difficult to control the amount of solder liquid, the chip resistor Due to limited volume and other problems, it can reduce short-circuit phenomenon, improve stability and effectiveness, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

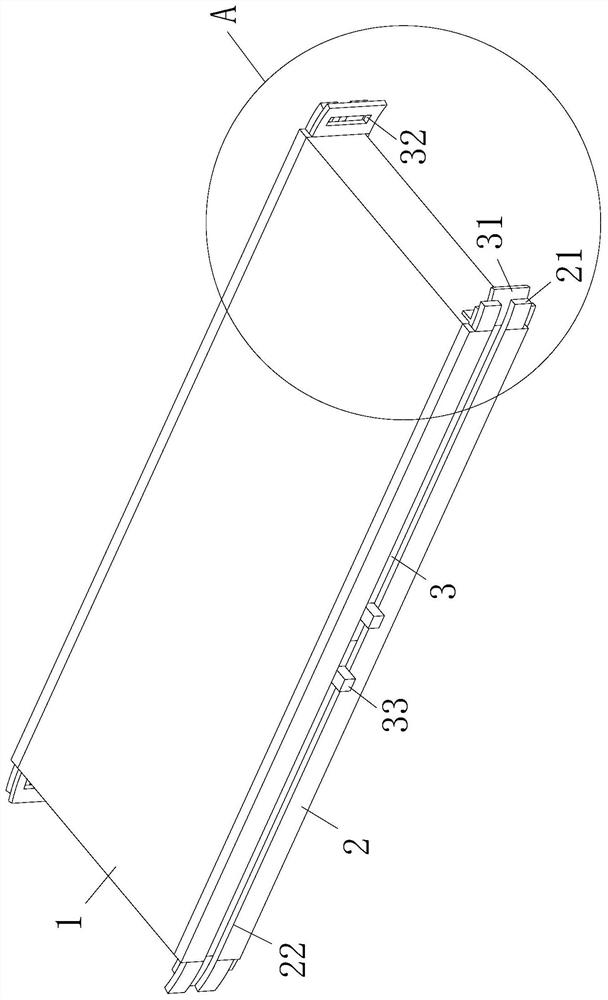

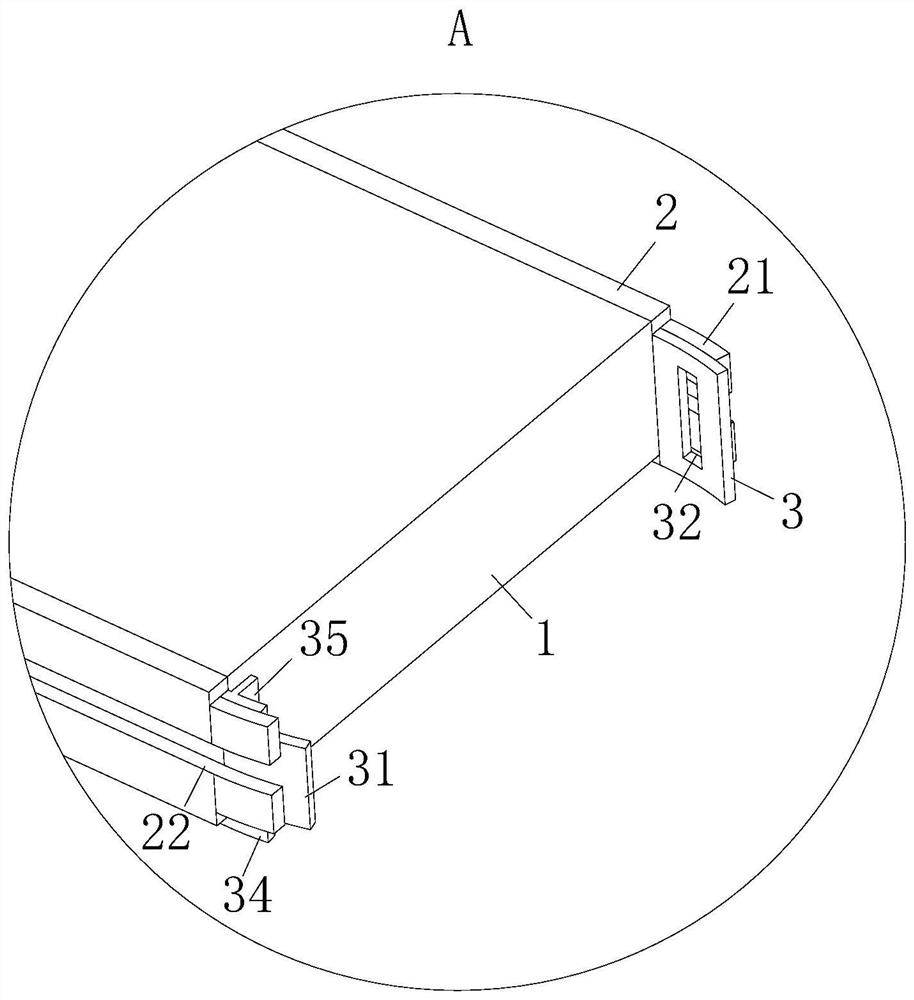

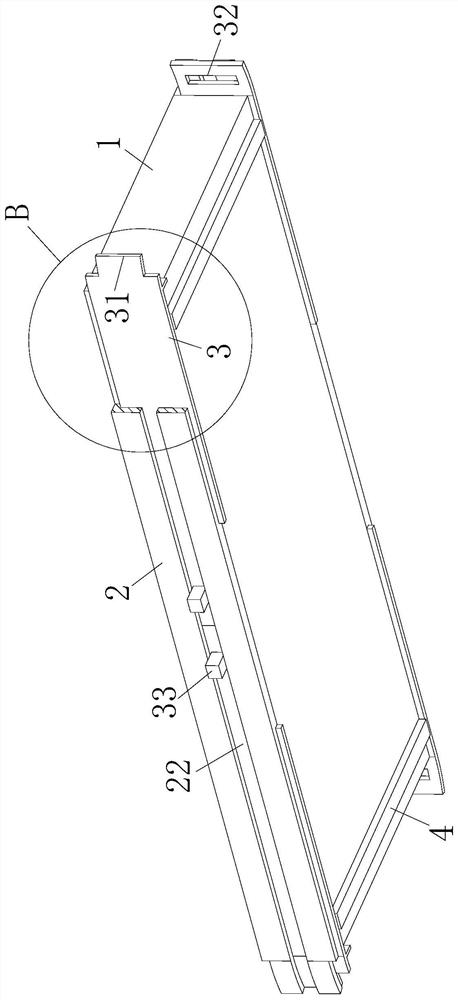

Image

Examples

Embodiment approach

[0026] As an embodiment of the present invention, the bottom end of the resistor body 1 is symmetrically bonded with a strip-shaped protective strip 4 along its length direction, and the protective strip 4 is made of elastic silicon rubber material; when working, when When the connecting plate welded with the resistor body 1 is uneven, the solder liquid inside the solder cavity 5 is easy to flow out from the gap between the bottom of the solder cavity 5 and the connecting plate, so that it is easy to make the solder liquid from the solder cavity 5 The outflowing solder liquid flows into the solder cavity 5 at the other end of the resistor body 1 and a short circuit occurs. At this time, a silicone rubber protective strip 4 that can withstand a certain high temperature is installed at the bottom of the resistor body 1, so that the protective strip 4 is on the resistor body. 1 can be tightly attached to the uneven connecting plate, so that the protective strip 4 can effectively s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com