A Multifunctional Rotating Lens for Pipeline Inspection

A pipeline detection and multi-functional technology, which is applied in the direction of measuring devices, camera bodies, color TV parts, etc., can solve the problems of low efficiency of ring detection, low pixels of analog cameras, and low definition, so as to prevent winding Knotting or even breaking, eliminating the interference of lens fog, and detecting the effect of high definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

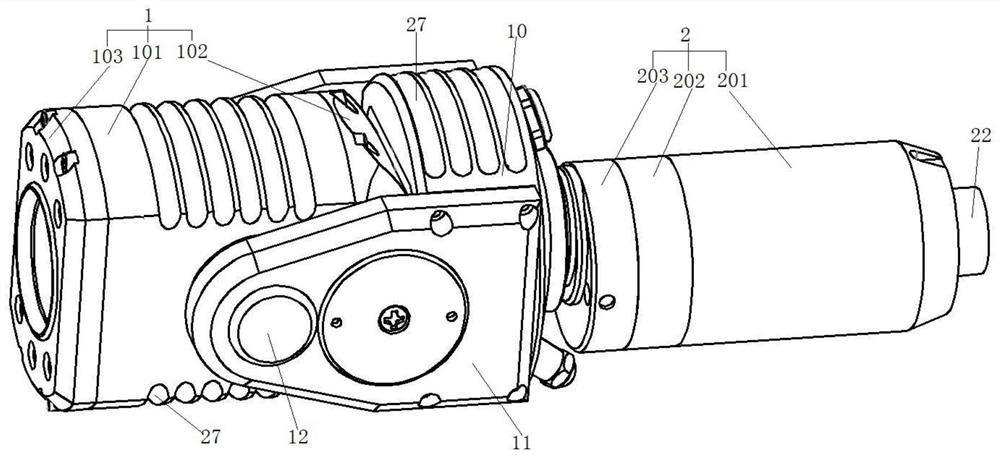

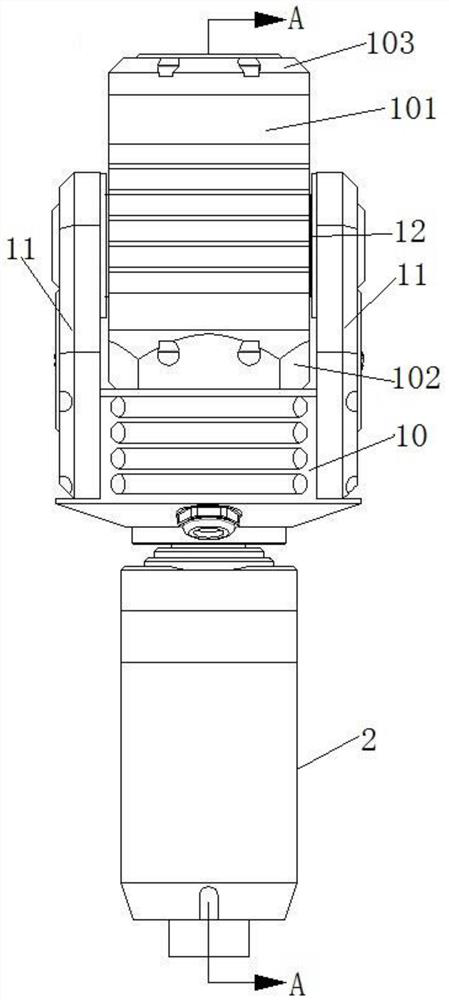

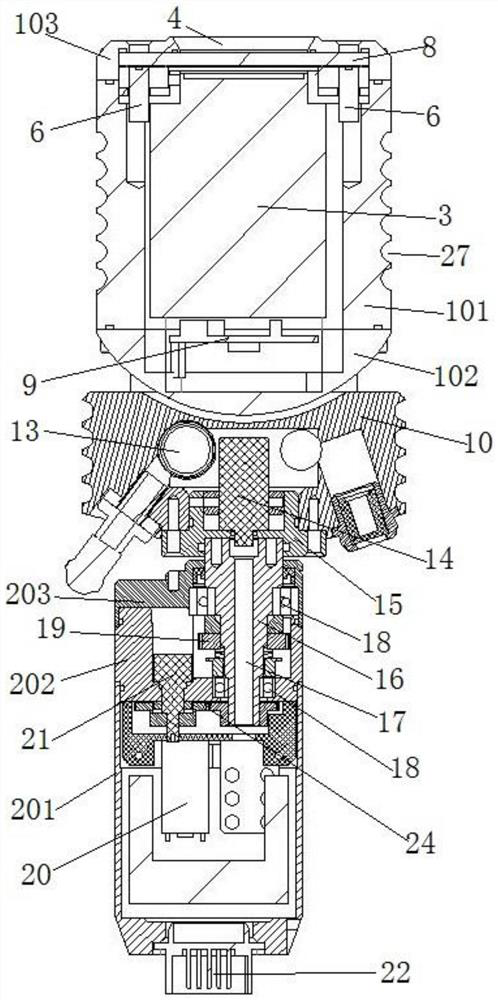

[0056] Such as Figure 1-8 As shown, a multifunctional rotating lens for pipeline detection, the rotating lens includes a lens body 1, a rotating assembly connected to the lens body 1, and an electronic control unit 2 connected to the rotating assembly;

[0057] The lens main body 1 includes a casing 101, a front end cover 103, and a rear end cover 102. A movement 3 is arranged inside the casing 101, and a glass lens is arranged on the front end cover 103 corresponding to the movement 3 4. The inner side of the glass lens 4 is provided with a lens heating wire 5, and the two sides of the glass lens 4 are provided with a pair of parallel laser beams 6, and the laser beams 6 pass through the fixing plate 8 and the glass lens 4, the The front end cover 103 is packaged together at the end of the casing 101; the inner side of the rear end cover 102 is provided with a signal adapter plate 9 connected to the movement 3, and the rear end cover 102 is connected to the signal The adapt...

Embodiment 2

[0082] This embodiment provides the working mode of the rotating lens in the first embodiment when performing pipeline inspection.

[0083] specific as Figure 9 As shown, the rotating lens is connected with the aviation socket 29 on the platform on the robot car body 28 through the aviation plug 22, and adopts a spiral slot type locking structure to fix and seal; the rotating lens is fixed and sealed with the robot car body 28 are placed together in the pipeline for pipeline detection, and the host computer connected to the robot car body 28 monitors through video;

[0084] When working, move the pipeline robot system to the top of the pipeline detection well, power on to check the working conditions of the entire system, put the pipeline robot body 28 and the rotating lens into the pipeline mouth through the rope and the tail cable as a whole, turn on the lights, and set the parameters. The robot car body 28 and the rotating lens are controlled to advance in the pipeline th...

Embodiment 3

[0086] This embodiment provides the detection steps that the rotating lens in Embodiment 1 will be applied to when performing pipeline detection, specifically as follows:

[0087] (1) Defog control: When the lens body 1 in the pipeline is found to be foggy on the video, turn on the lens heating wire 5 to heat through the defogging button on the control software, and the heating wire will automatically power off after two minutes. If there is still fog You can click the defogging button again and repeat until the fog is eliminated;

[0088] (2) Rotation control: When a circular defect appears on the video, the robot body 28 is controlled by software to move to the vicinity of the defect, and the lens main body 1 is controlled to tilt up so that the circumferential defect is in the middle of the video screen, and then the lens main body 1 is controlled horizontally at 360° Rotate one circle at a degree to observe and record the entire circumferential defect picture, and then cli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com