Garbage combustion fly ash filtering device based on local membrane separation

A technology of garbage burning and filtering device, applied in the direction of combined device, separation method, dispersed particle separation, etc., can solve the problems of unfavorable environmental governance, sustainable development, waste of water resources, etc., to improve viscosity, facilitate maintenance and replacement, and improve filtration. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

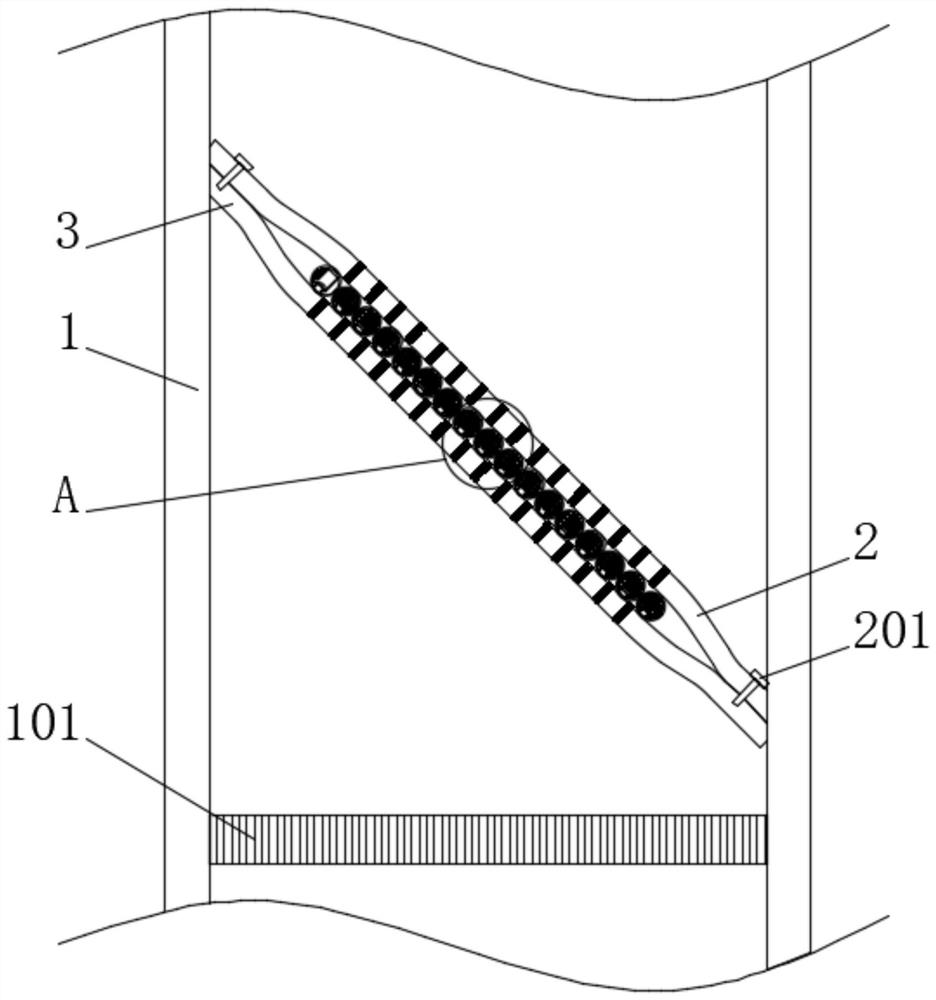

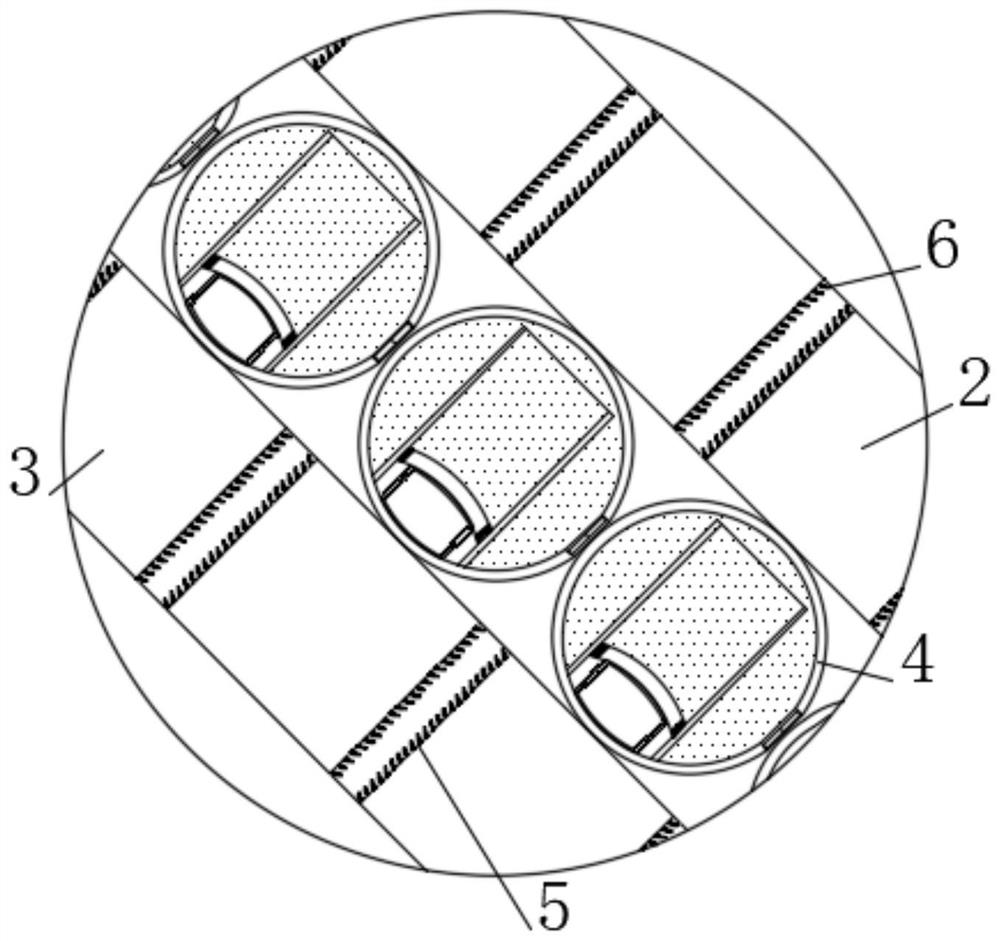

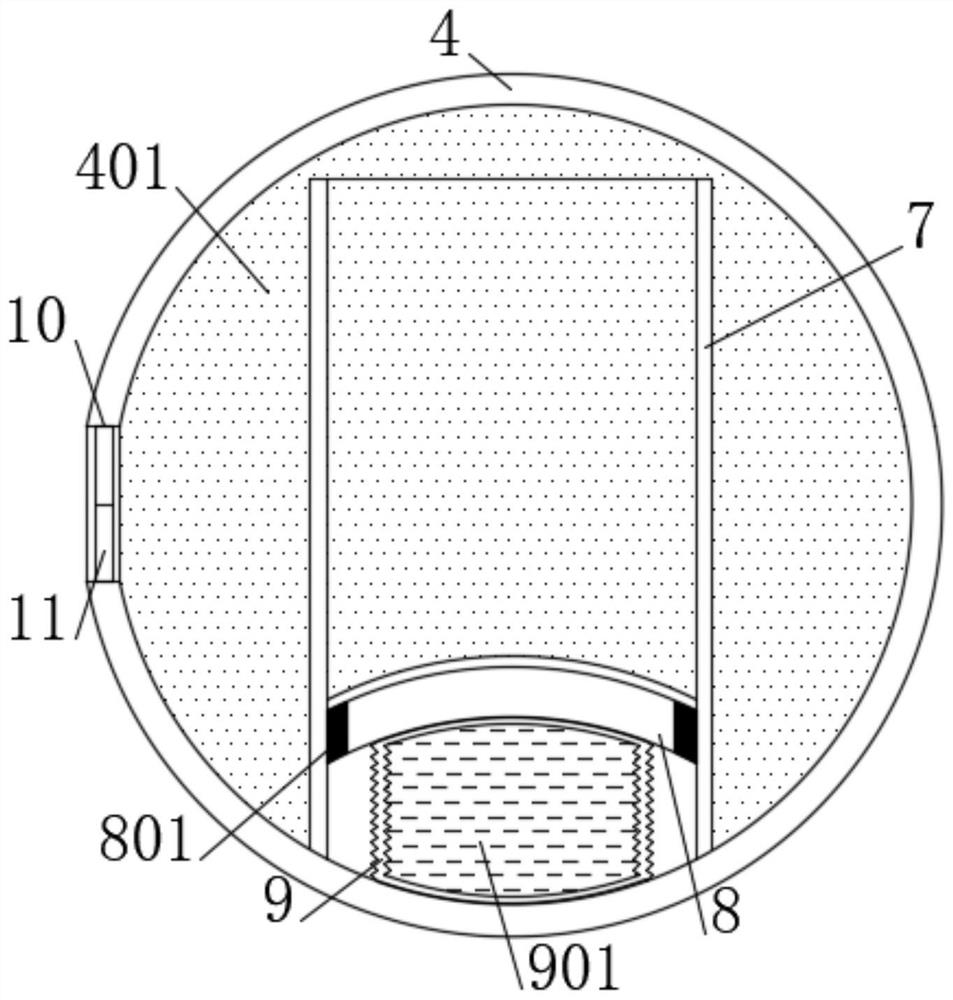

[0043] see Figure 1-5 , a garbage combustion fly ash filter device based on partial membrane separation, comprising an exhaust pipe 1, the inner wall of the exhaust pipe 1 is provided with a filter membrane, the filter membrane includes an upper filter membrane 2 and a lower filter membrane 3, the lower filter membrane 3 is connected with the exhaust The inner wall of the gas pipeline 1 is fixedly connected, the upper filter membrane 2 is offset against the inner wall of the exhaust pipeline 1 and is fixedly connected with the lower filter membrane 3, and a plurality of evenly distributed slow-release balloons 4 are arranged between the upper filter membrane 2 and the lower filter membrane 3 After the airbag 9 in the slow-release balloon 4 is heated, it continues to squeeze the arc-shaped movable piece 8 and moves up until the slow-release balloon 4 changes into an ellipsoid shape, so that the upper and lower ends of the slow-release balloon 4 are streamlined, thereby Increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com