Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of complex synthesis methods, poor environmental friendliness, and poor cycle performance, and achieves simple synthesis methods and morphology. Easy-to-control, high rate-capable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

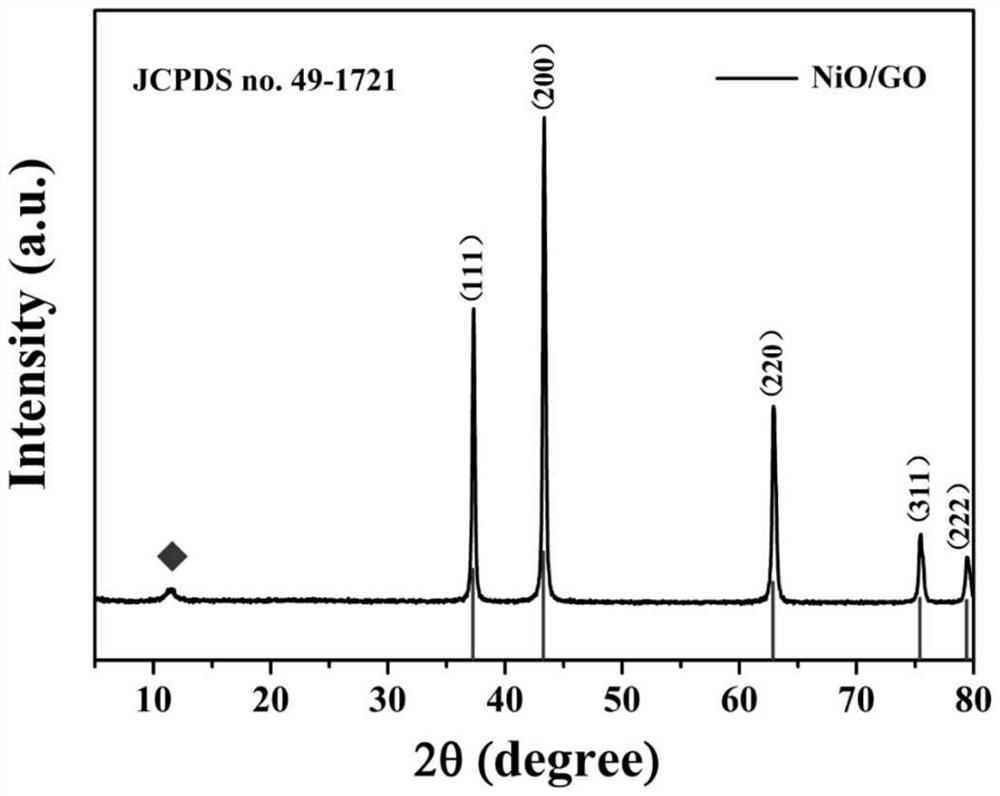

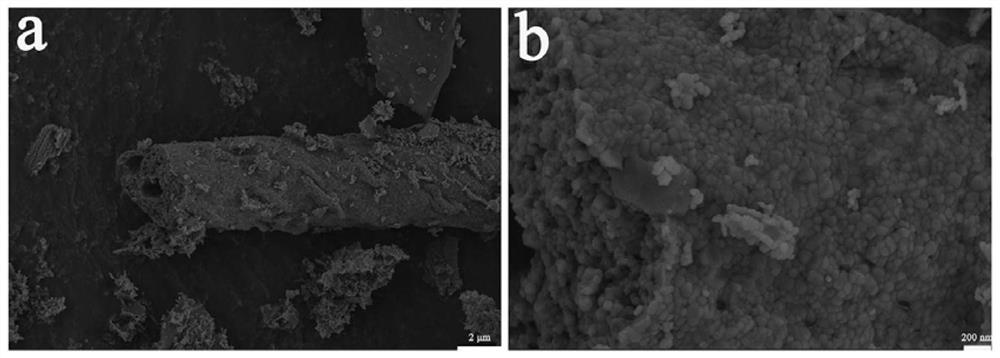

[0041] A negative electrode material for a lithium ion battery, comprising a hollow tubular NiO and a carbon coating covering the hollow tubular NiO; the preparation method of the negative electrode material for a lithium ion battery comprises the steps of:

[0042] S11: Prepare nickel nitrate solutions with a molar concentration of 0.1mol / L, 0.25mol / L, 0.5mol / L or 0.75mol / L respectively;

[0043] S12: adding 1.7-2 g of absorbent cotton to the nickel nitrate solution of different concentrations after being completely dissolved, soaking for 6 hours, and drying at 70° C. for 18 hours to obtain a precursor of absorbent cotton;

[0044] S13: Calcining the above-mentioned absorbent cotton precursor in an air atmosphere to obtain pure-phase nickel oxide (NiO);

[0045] The calcination process: firstly calcine at 300°C for 1 hour, and then calcine at 600°C for 2 hours.

Embodiment 2

[0047] A negative electrode material for a lithium ion battery, comprising a hollow tubular NiO and a carbon coating covering the hollow tubular NiO; the preparation method of the negative electrode material for a lithium ion battery comprises the steps of:

[0048] S21: preparing a nickel acetate solution with a molar concentration of 0.25mol / L;

[0049] S22: adding 1.8 g of absorbent cotton to the above-mentioned completely dissolved nickel acetate solutions of different concentrations, soaking for 6 hours, and drying at 70° C. for 18 hours to obtain a precursor of absorbent cotton;

[0050] S23: Calcining the above-mentioned absorbent cotton precursor in an air atmosphere to obtain pure-phase nickel oxide (NiO);

[0051] The calcination process: firstly calcine at 300°C for 1 hour, and then calcine at 600°C for 2 hours.

Embodiment 3

[0053] A negative electrode material for a lithium ion battery, comprising a hollow tubular NiO and a carbon coating covering the hollow tubular NiO; the preparation method of the negative electrode material for a lithium ion battery comprises the steps of:

[0054] S31: Select the best pure-phase NiO synthesized in the above-mentioned Example 1 and Example 2 as a precursor;

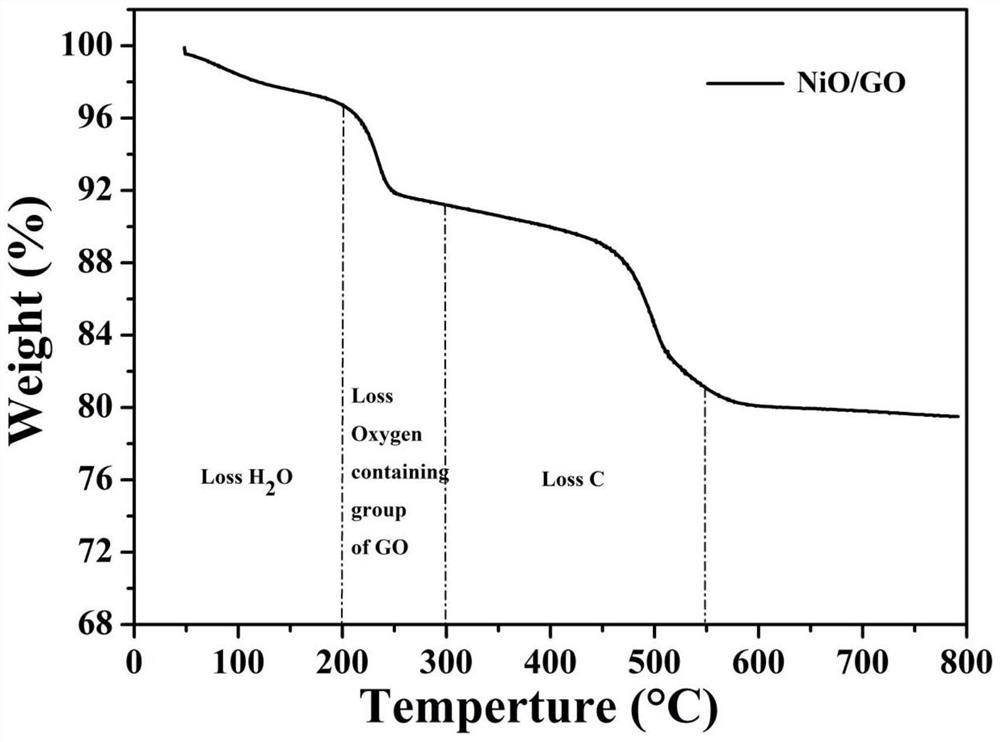

[0055] S32: adding the above-mentioned precursor pure-phase NiO to graphene oxide (GO) solutions with a concentration of 2 mg / mL, 4 mg / mL, and 6 mg / mL, respectively, heating, stirring, evaporating and crystallizing at 60°C, and obtaining a NiO / GO composite material;

[0056] S33: drying the above-mentioned NiO / GO composite material at 70° C. for 18 hours by blowing air to obtain an anode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com