Pretreatment system and method for organic industrial wastewater difficult to biodegrade

A technology that is difficult to biodegrade and industrial wastewater is applied in the field of pretreatment systems for organic industrial wastewater, which can solve the problems of inability to take into account the treatment effect and cost, and achieve the effects of simple structure, easy manufacture, and improved biodegradability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

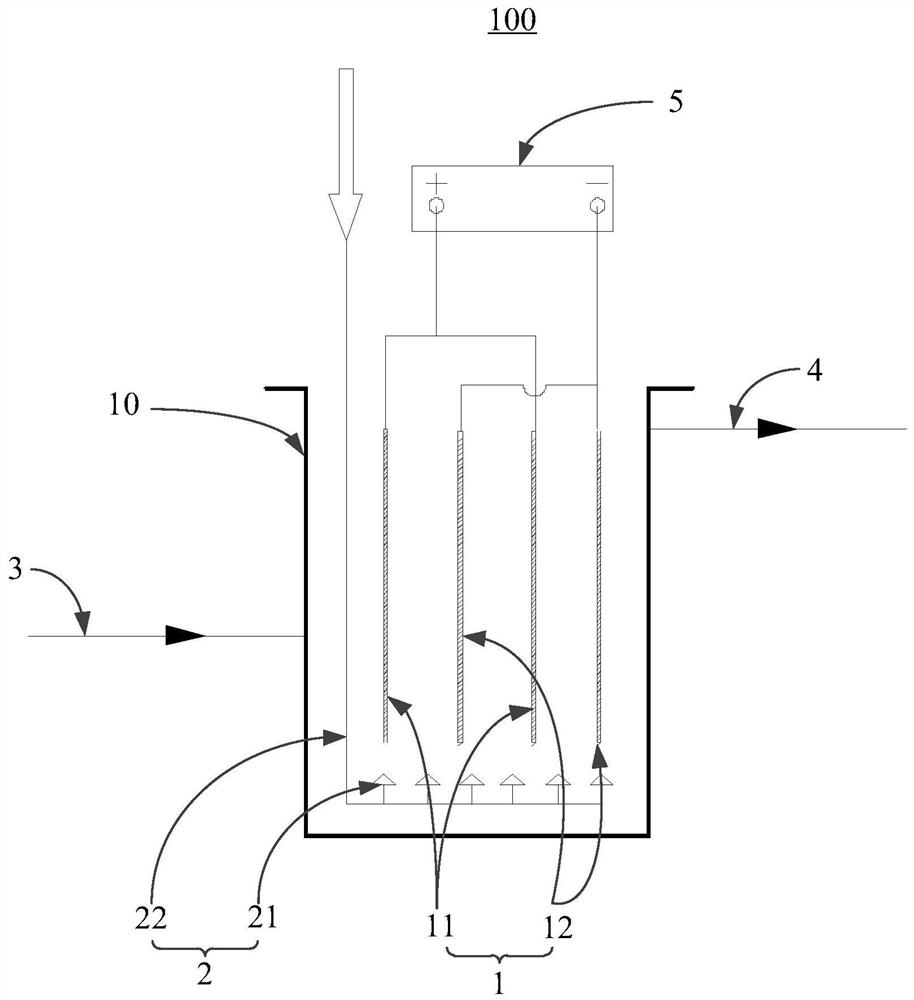

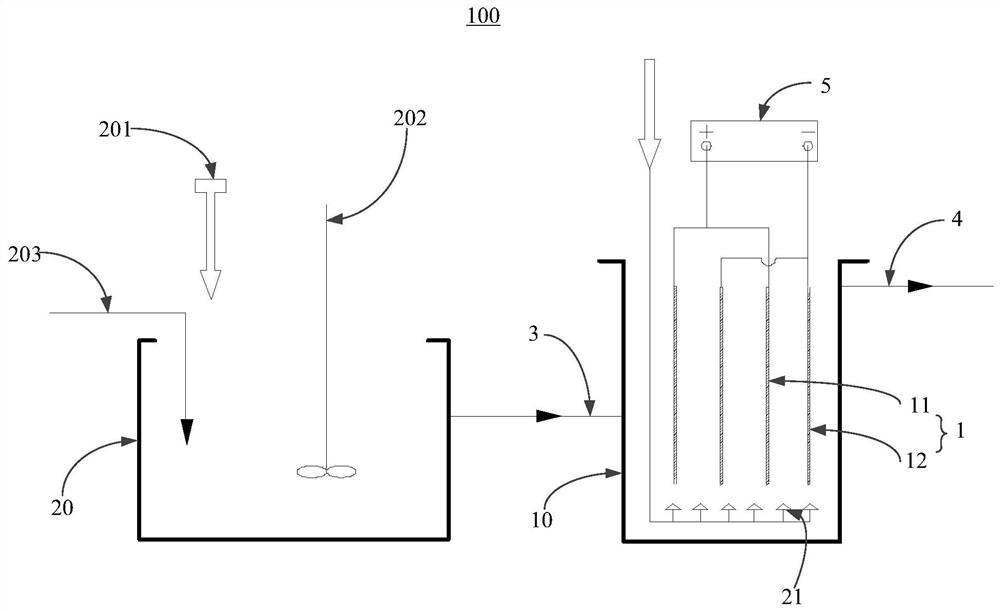

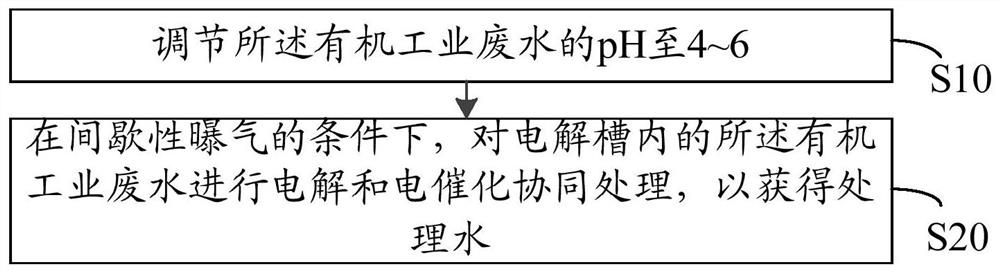

[0053] An acid-base regulator is put into the acid-base regulating tank 20, so that the pH of the organic wastewater therein is 5.2. The organic waste water enters the electrolytic cell 10 .

[0054] In the electrode plate group 1, the distance between the anode plate 11 and the cathode plate 12 is 3cm; the hydraulic retention time of the organic wastewater in the electrolytic cell 10 is set to 50min; the power supply is connected to the electrode plate group 1 to supply power, and the current density is set to 12mA / cm 2 . Start the power supply 5 to start electrolysis, then start the air compression equipment, and start periodic aeration. The air-water ratio in the aeration stage is 1.5:1, and in one cycle, the aeration time and stop aeration time are both 25 minutes.

[0055] Sampling the treated water at the water outlet 4 of the electrolytic cell 1, using a COD analyzer and a BOD detector to detect the CODcr content and BOD of the treated water respectively, and calculate...

Embodiment 2

[0057] An acid-base regulator is put into the acid-base regulating pool 20, so that the pH of the organic wastewater therein is 4. The organic waste water enters the electrolytic cell 10 .

[0058] In the electrode plate group 1, the distance between the anode plate 11 and the cathode plate 12 is 2.5cm; the hydraulic retention time of the organic waste water in the electrolytic cell 10 is set to be 35min; the power supply is connected to the electrode plate group 1 to supply power, and the current density is set to 6mA / cm 2 . Start the power supply 5 to start electrolysis, then start the air compression equipment, and start periodic aeration. The air-water ratio in the aeration stage is 3:1, and within one cycle, the aeration time and stop aeration time are both 15 minutes.

[0059] Sampling the treated water at the water outlet 4 of the electrolytic cell 1, using a COD analyzer and a BOD detector to detect the CODcr content and BOD of the treated water respectively, and ca...

Embodiment 3

[0061] An acid-base regulator is put into the acid-base regulating pool 20, so that the pH of the organic wastewater therein is 6. The organic waste water enters the electrolytic cell 10 .

[0062] In the electrode plate group 1, the distance between the anode plate 11 and the cathode plate 12 is 4cm; the hydraulic retention time of the organic wastewater in the electrolytic cell 10 is set to 90min; the power supply is connected to the electrode plate group 1, and the current density is set to 20mA / cm 2 . Start the power supply 5 to start electrolysis, then start the air compression equipment, and start periodic aeration. The air-water ratio in the aeration stage is 1.2:1, and within one cycle, the aeration time and stop aeration time are both 30 minutes.

[0063] The treated water was sampled at the water outlet 4 of the electrolytic cell 1, the CODcr content and BOD of the treated water were detected by a CODcr analyzer and a BOD detector, and the BOD / CODcr value was calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com