High-strength impermeable anti-freezing concrete and preparation method thereof

A concrete and high-strength technology, applied in the field of concrete, can solve the problems of poor impermeability, cracking, and poor cement bonding and fusion, and achieve the effect of improving frost resistance and compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

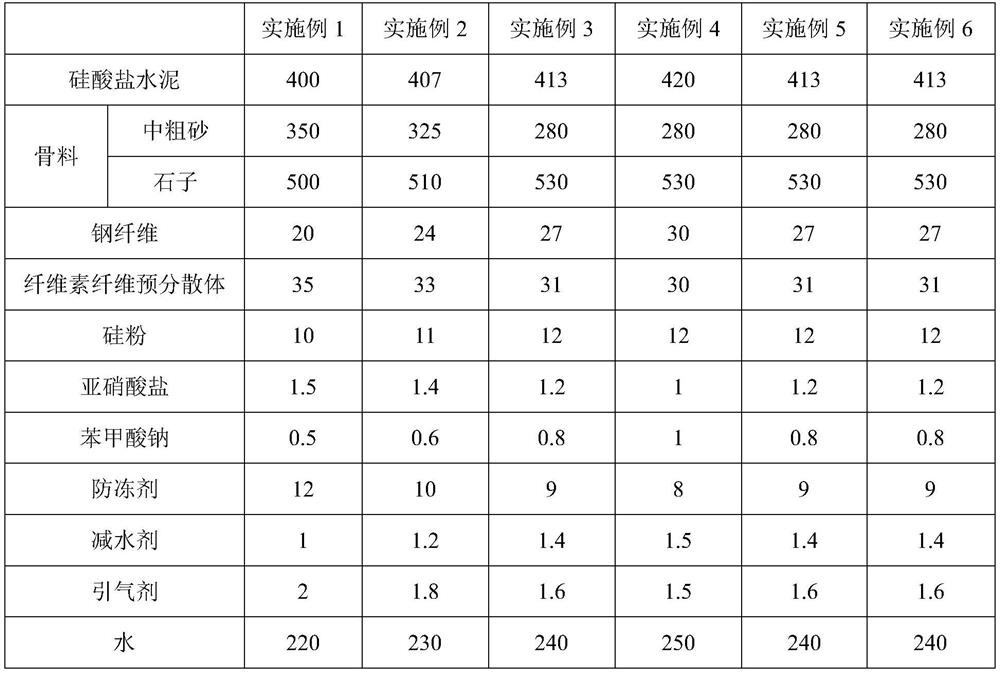

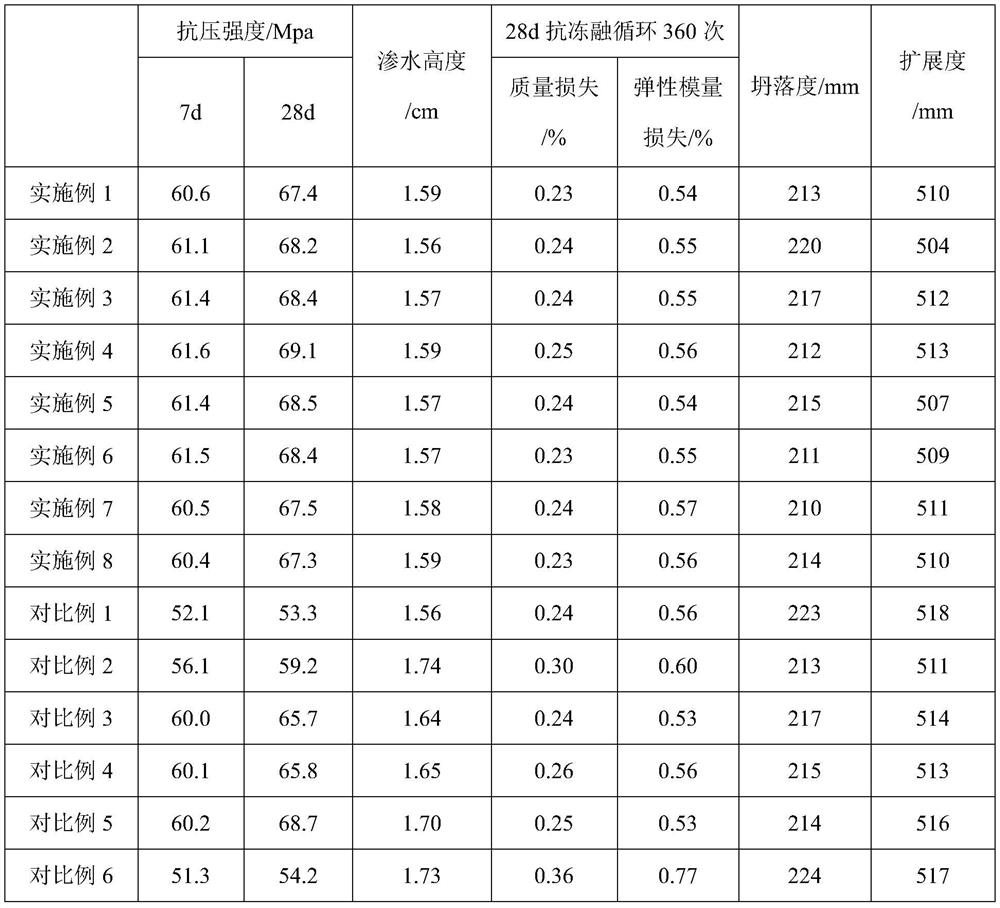

Examples

preparation example 1

[0036] The components and the contents of each component of the cellulose fiber predispersion of Preparation Example 1 are shown in Table 1. The preparation steps of the cellulose fiber predispersion are: add the silane coupling agent to water, stir until dissolved, and then add After stirring the cellulose fiber for 10 minutes, add fine sand and stir for 1 hour to obtain the cellulose fiber predispersion.

[0037] Each component of the cellulose fiber predispersion of table 1 preparation example 1-3 and the amount (kg) of each component

[0038] raw material Preparation Example 1 Preparation example 2 Preparation example 3 Cellulose Fiber 1 1.2 1.5 fine sand 15 12 10 A silane coupling agent 5 6 7 water 15 13 10

preparation example 2

[0040] The components of the cellulose fiber predispersion of Preparation Example 2 and the contents of each component are shown in Table 1. The preparation steps of the cellulose fiber predispersion are: add the silane coupling agent to water, stir until dissolved, and then add After stirring the cellulose fibers for 20 minutes, add fine sand and stir for 1.5 hours to obtain the cellulose fiber predispersion.

preparation example 3

[0042] Each component of the cellulose fiber predispersion of Preparation Example 3 and the content of each component are shown in Table 1. The preparation steps of the cellulose fiber predispersion are: add the silane coupling agent to water, stir until dissolved, and then add After stirring the cellulose fibers for 10 minutes, add fine sand and stir for 2 hours to obtain a cellulose fiber predispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com