One-step preparation method and product of polyimide open-cell foam

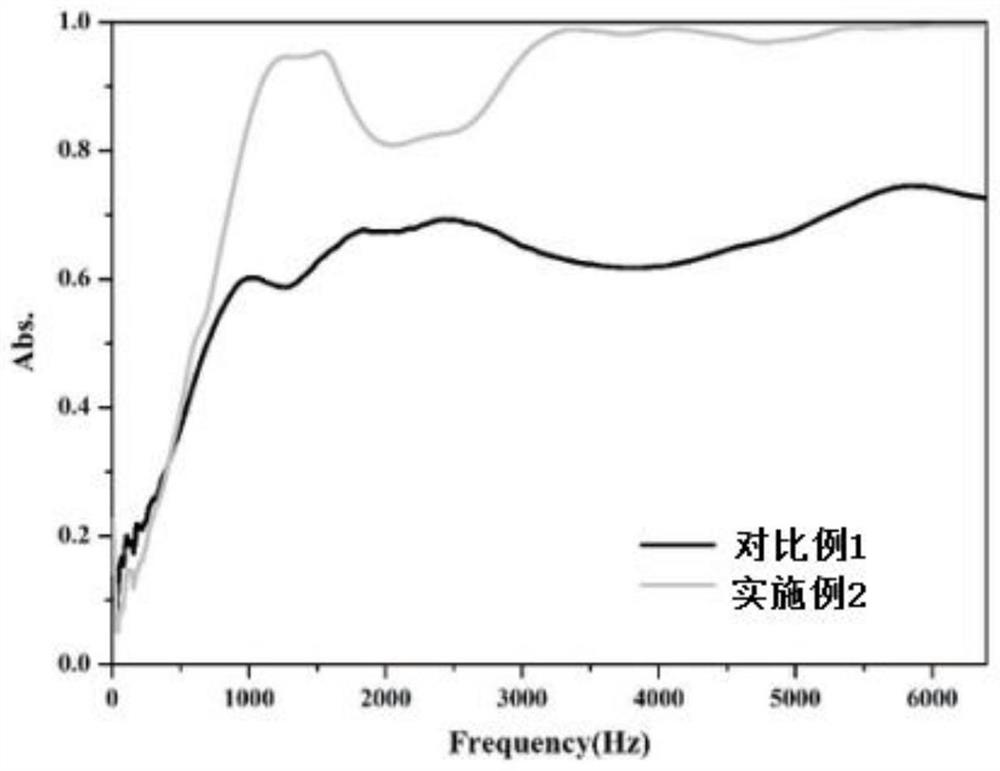

A technology of polyimide and open-cell foam, which is applied in the field of polyimide foam material and its preparation, can solve problems such as inability to meet the lightweight requirements of application equipment, complex design and production process, and poor sound absorption performance. Achieve the effects of improving the possibility of heat convection and heat transfer, simplifying the production process, and improving sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1. The method for preparing polyimide open-cell foam by one-step method comprises the following steps:

[0026] Step 1: Proportionally dissolving the corresponding mass of organic acid additives in the polar solvent solution of diacid diester, stirring evenly to obtain foaming slurry A;

[0027] Step 2: mixing the catalyst, foam stabilizer and foaming agent uniformly in proportion to obtain foaming slurry B;

[0028] Step 3: Weighing polyisocyanate of corresponding quality as foaming slurry C; and keeping foaming slurry C at the same temperature as foaming slurry A and foaming slurry B;

[0029] Step 4: Mix foaming slurry A, foaming slurry B and foaming slurry C, stir with a high-speed agitator for 5 to 30 seconds, and then pour into a mold for foaming to obtain a polyimide foam intermediate;

[0030] Step 5: Demould the polyimide foam intermediate and place it in a blast drying oven heated to 90-120°C in advance, and then raise the temperature of the blast dr...

Embodiment 2

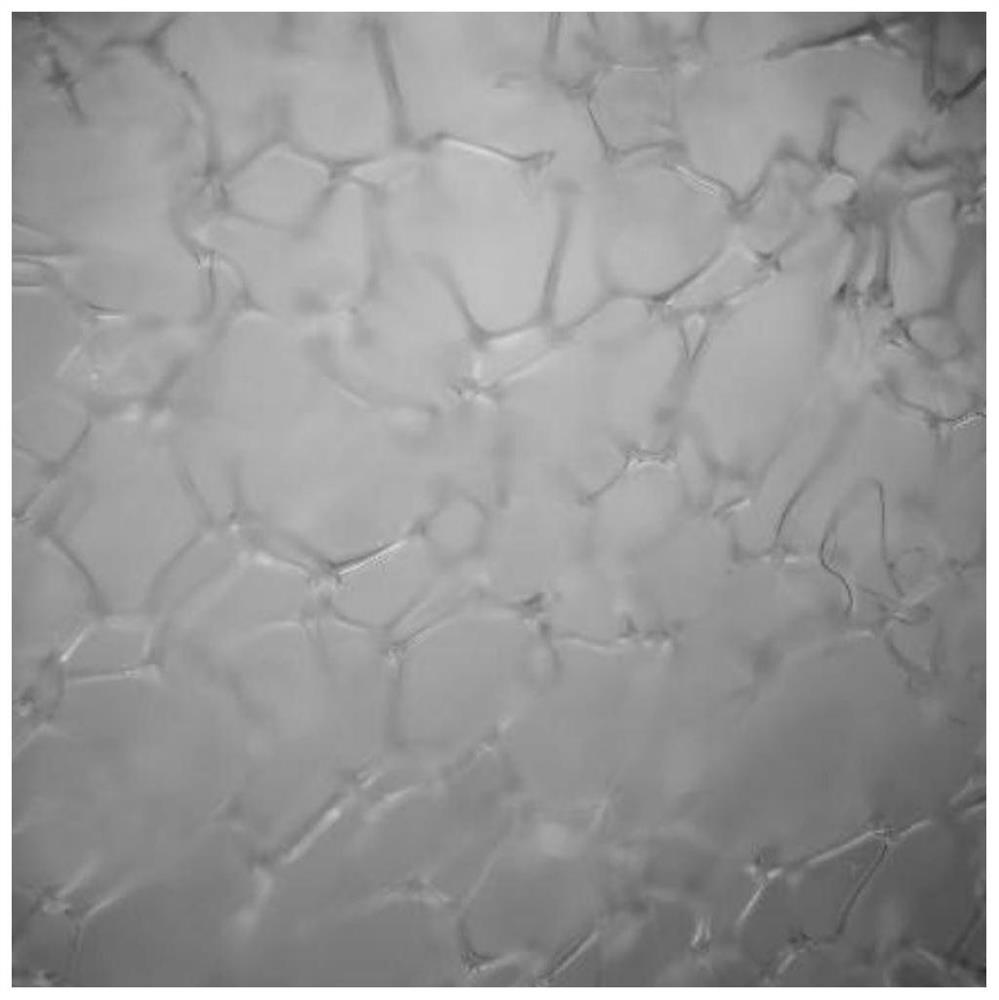

[0040] Example 2. In a disposable plastic cup, dissolve 10g of oxalic acid in 40g of N,N-dimethylformamide solution of dimethyl 3,3',4,4'-benzophenone tetraate, stir evenly to obtain foam Slurry A: In a disposable plastic cup, add 3.2g of a catalyst prepared by T12, Dabco33, and triethanolamine in a mass ratio of 1:2:5, and 10g of a catalyst prepared by AK8805 and PEG600 in a mass ratio of 1:1 The formed foam stabilizer and 4.8g deionized water were mixed evenly to obtain foaming slurry B; 60g of polyisocyanate weighed was added in a disposable plastic cup as foaming slurry C; Foam slurry A, foam slurry B and foam slurry C are mixed, stirred with a high-speed mixer for 10s, poured into a mold for foam molding to obtain a polyimide foam intermediate; remove the polyimide foam intermediate The mold is placed in a blast drying oven that has been heated up to 100°C in advance, and then the blast drying oven is heated to 180°C at a rate of 5°C / min to complete the transformation fr...

Embodiment 3

[0042] Example 3. In a disposable plastic cup, dissolve 11g of oxalic acid in 44g of N,N-dimethylacetamide solution of diethyl 3,3',4,4'-biphenyltetraate, stir evenly to obtain a foaming slurry A; In a disposable plastic cup, sequentially add 4g of a catalyst prepared by T12, Dabco33, and triethanolamine in a mass ratio of about 0.7:2:5, and 10g of a catalyst prepared by AK8805 and PEG600 in a mass ratio of 1:1 The foam stabilizer and 5.0g deionized water were mixed evenly to obtain foaming slurry B; 60g of polyisocyanate was weighed and added to a disposable plastic cup as foaming slurry C; the foaming material at about 20°C Slurry A, foaming slurry B and foaming slurry C are mixed, stirred with a high-speed mixer for 8-10s, and poured into a mold for foaming to obtain a polyimide foam intermediate; the foam intermediate is demoulded and placed in a pre- Raise the temperature to 100°C in a blast drying oven, then raise the temperature of the blast drying oven to 180°C at a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com