Impedance composite resonance magnetic motorcycle silencer

An impedance compounding, motorcycle technology, applied in mufflers, machines/engines, engine components, etc., can solve the problems of easily endangering the safety of motorcycles, affecting the stability of motorcycle exhaust pipes, reducing service life, etc., to protect the environment Health, prolong equipment life, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

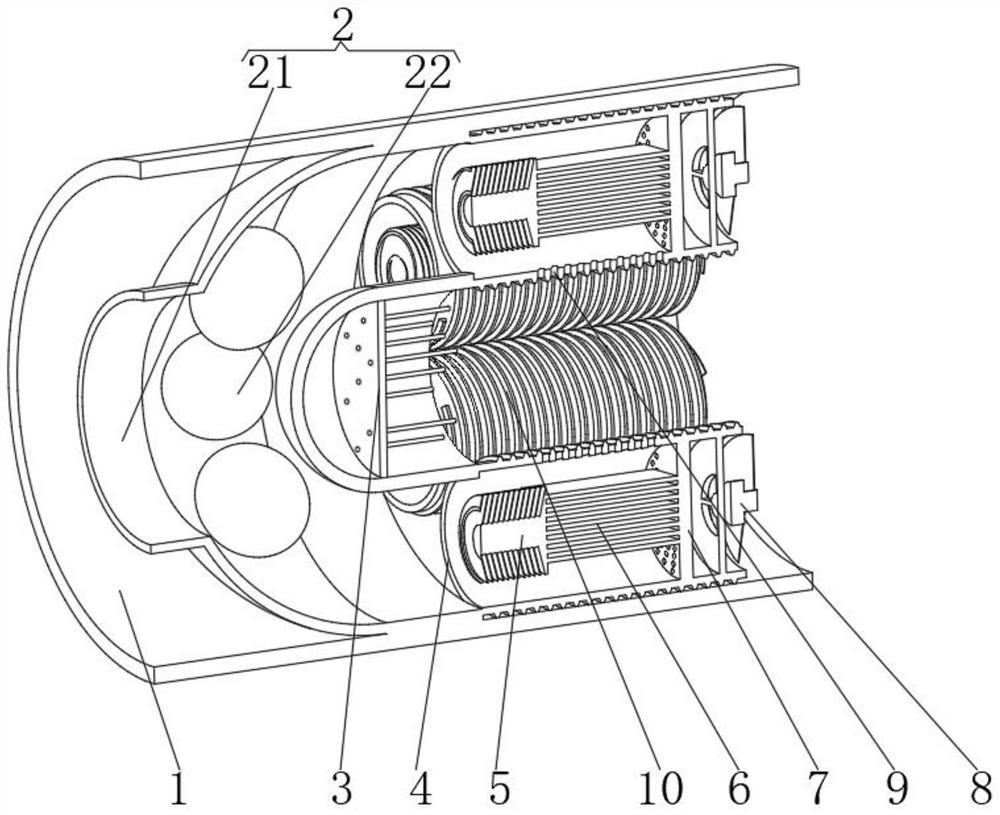

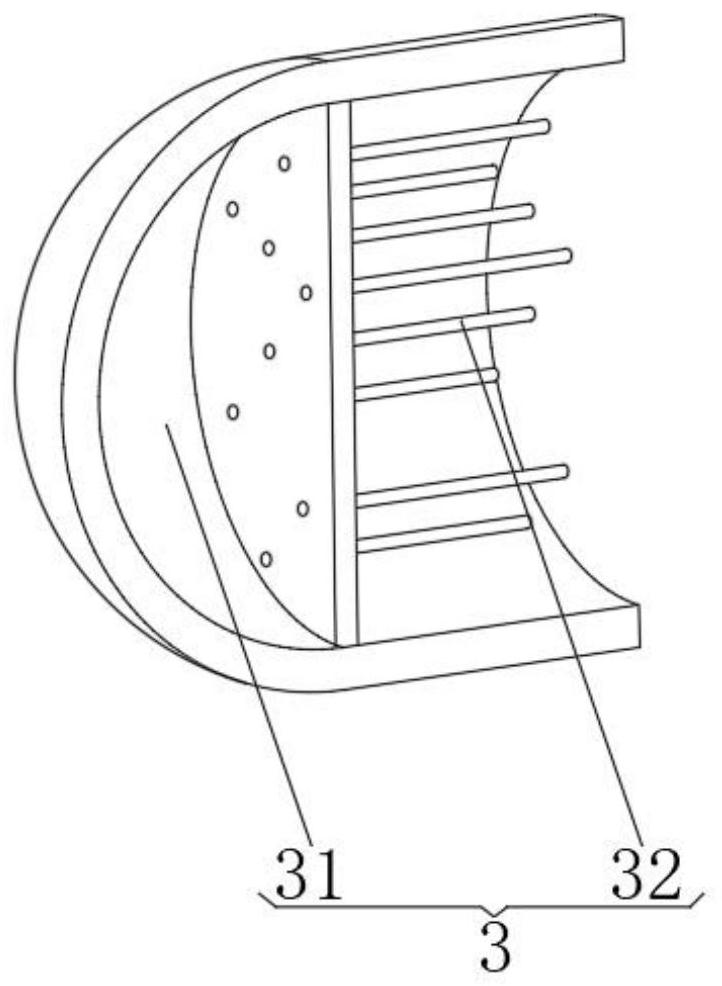

Embodiment 1

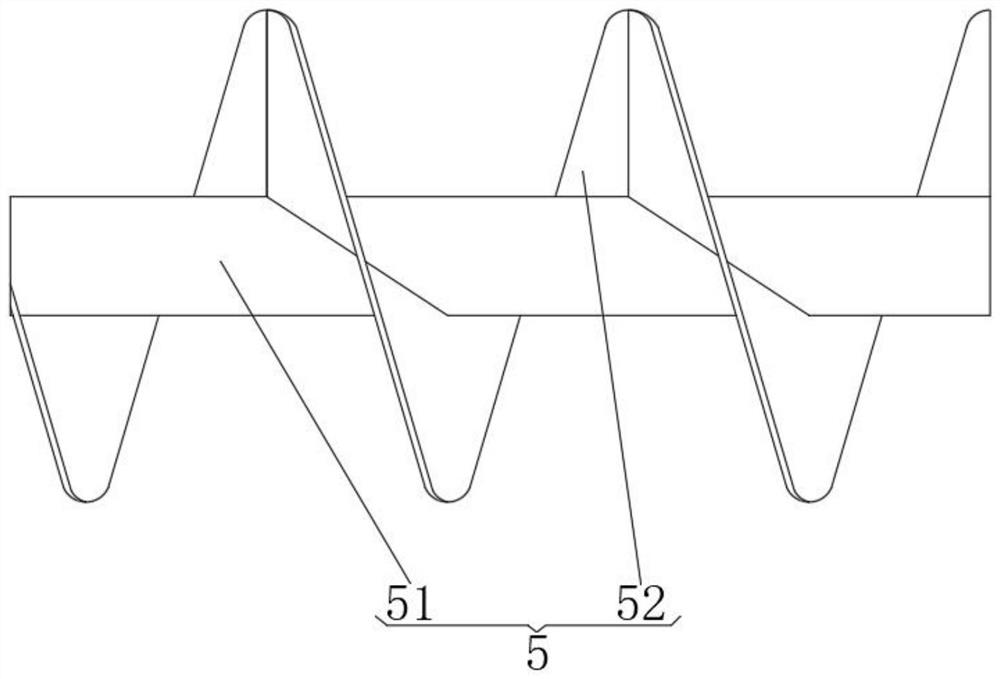

[0046] When in use, the tail gas enters the U-shaped draft tube 21 through the installation pipe 1 for diversion, and drives the elliptical ball 22 to move in the U-shaped draft tube 21. Through the thermal expansion effect, the volume of the elliptical ball 22 increases. A stop is formed in the flow tube 21 to concentrate the heat and conduct it to the spherical oil bottle 31 in the lubricating mechanism 3. The exhaust gas purification catalyst is being filled in the spherical oil bottle 31, and the volume changes through heat conduction. 32 to spray the outer surface of the convection cylinder 4, the tail gas enters the convection cylinder 4 after passing through the U-shaped guide pipe 21, and the spiral plate 52 is used to guide the airflow in a new way, so that the airflow spirals forward in the convection cylinder 4, Blow the resonance plate 64 and the auxiliary vibration plate 65, so that the resonance plate 64 and the auxiliary vibration plate 65 vibrate, and drive the ...

Embodiment 2

[0048] On the basis of Embodiment 1, the exhaust gas passes through the vent hole 72 to drive the gasket 73 to change its position, so that the position of the permanent magnet 76 changes, the magnetic field changes, and the electromagnetic induction motor 83 is driven to start, so that the suction fan blade 85 rotates. Inhale the external air to cool down the magnet to ensure its magnetism, and infuse it into the rotating resonance mechanism 6 through the cavity 74 and the vent hole 72 to form the convective collision of the airflow, assist in noise reduction, and cool down to ensure the use of the equipment Safety.

[0049] It should be noted that different substances such as catalyst, lubricating oil and cleaning agent can be added to the spherical oil bottle 31 to achieve different effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com