A kind of green moisture conservation and slow-release compound organic cultivation substrate and preparation method thereof

A cultivation substrate and organic technology, applied in the field of organic cultivation substrates and preparation thereof, can solve the problems of loose structure and poor gelling ability of a water-retaining agent, and achieve the effects of easy degradation, low cost and high water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

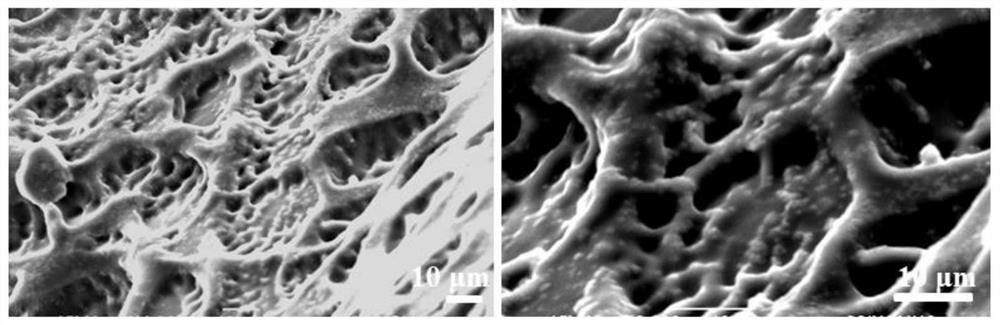

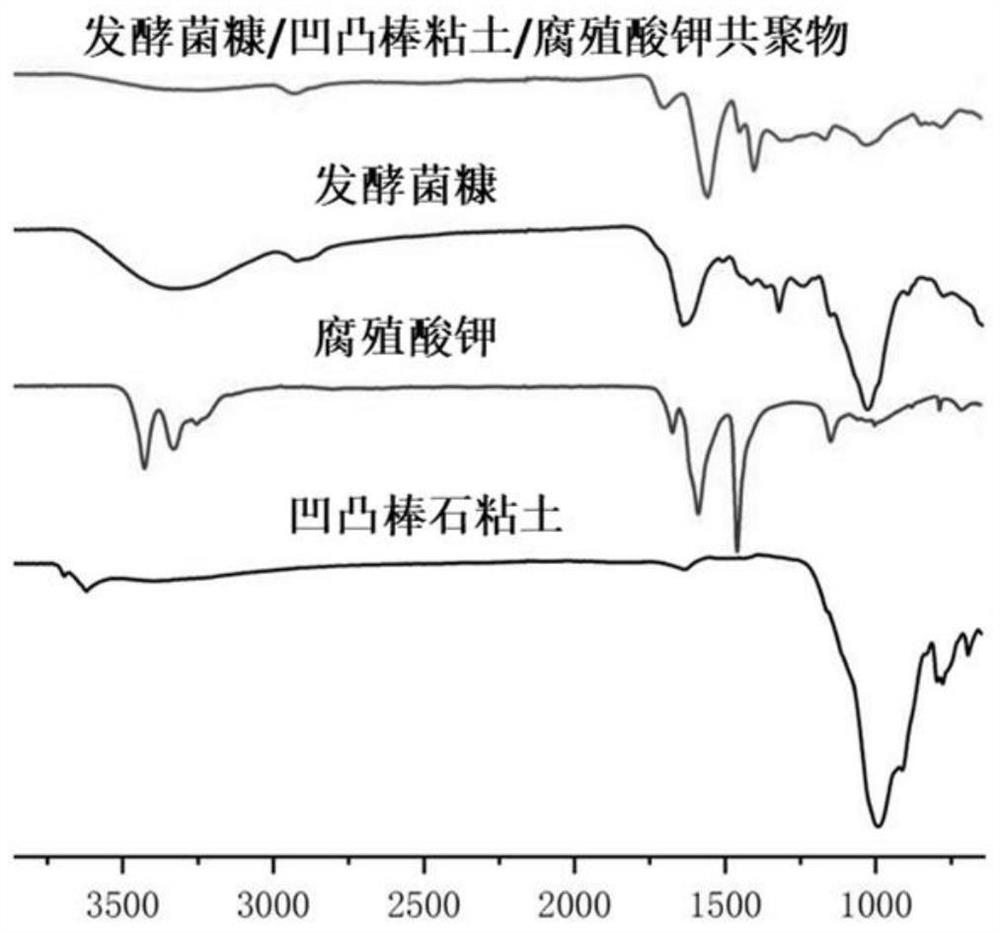

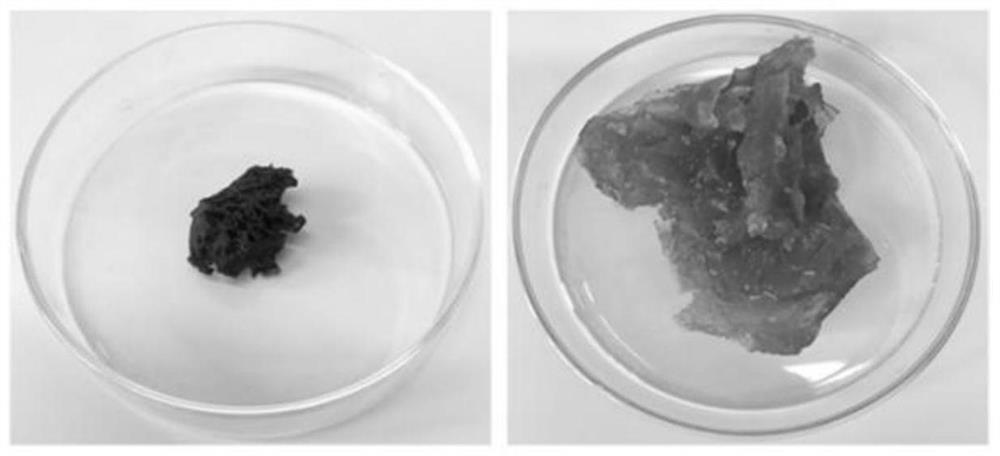

Image

Examples

Embodiment 1

[0041] (1) Send the attapulgite raw soil into a pulverizer for crushing, and sieve to obtain 150-mesh clay powder;

[0042] (2) Add the above-mentioned attapulgite clay powder into the sodium pyrophosphate solution with a mass concentration of 1.0%, stir at a high speed until uniformly mixed; then raise the temperature to 40°C, continue stirring for 1.0h, and after standing for stratification, extract the upper layer to suspend solution, and added H 3 PO 4 React until no bubbles escape;

[0043] (3) After ultrasonically dispersing the above suspension for 20 minutes, vigorously stir for 2.5 hours, then age at room temperature for 24 hours, use a high-speed centrifuge to discard the supernatant liquid, and collect the lower layer solid; put it in an oven at 80°C and grind it finely. Pass through a 200-mesh sieve for standby;

[0044] (4) Repeatedly wash the fermented mushroom chaff with distilled water until there is no residue; after drying at 40°C, put it into a ball mill ...

Embodiment 2

[0059] (1) Send the attapulgite raw soil into a pulverizer for crushing, and sieve to obtain 200-mesh clay powder;

[0060] (2) Add the above-mentioned attapulgite clay powder into the sodium pyrophosphate solution with a mass concentration of 2.0%, stir at a high speed until uniformly mixed; then raise the temperature to 40°C, continue stirring for 1.5h, and after standing for stratification, extract the upper layer to suspend solution, and add appropriate amount of H 3 PO 4 , react until no bubble escapes;

[0061] (3) After ultrasonically dispersing the above suspension for 30 minutes, vigorously stir for 5 hours, then age at room temperature for 24 hours, use a high-speed centrifuge to discard the supernatant, and collect the lower solid; 200-mesh sieve for spare;

[0062] (4) Repeatedly wash the bran of Agaricus bisporus fermentation bacteria with distilled water until there is no residue; after drying at low temperature, put it into a ball mill and grind for 10 minute...

Embodiment 3

[0075] (1) Send the attapulgite raw soil into a pulverizer for crushing, and sieve to obtain 200-mesh clay powder;

[0076] (2) Add the above-mentioned attapulgite clay powder into the sodium pyrophosphate solution with a mass concentration of 2.5%, stir at a high speed until uniformly mixed; then raise the temperature to 45°C, continue stirring for 1.5h, after standing for stratification, extract the upper layer to suspend solution, and added H 3 PO 4 React until no bubbles escape;

[0077] (3) After ultrasonically dispersing the above suspension for 40 minutes, vigorously stir for 4.5 hours, then age at room temperature for 36 hours, use a high-speed centrifuge to centrifuge, discard the supernatant, and collect the lower solid; put it in an oven at 95°C and grind it finely. Pass through a 200-mesh sieve for standby;

[0078] (4) Repeatedly wash the chaff of fermented fungus with distilled water until there is no residue; after drying at 60°C, put it into a ball mill and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com