French bread frozen fermented dough containing citrus fiber and preparation method and application thereof

A citrus fiber, fermented dough technology, applied in the direction of dough preparation, application, dough processing, etc., can solve problems such as poor taste and texture, weight loss of bread products, damage to gluten structure, etc., to promote the development of diversified products, The effect of satisfying diversified consumption needs and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

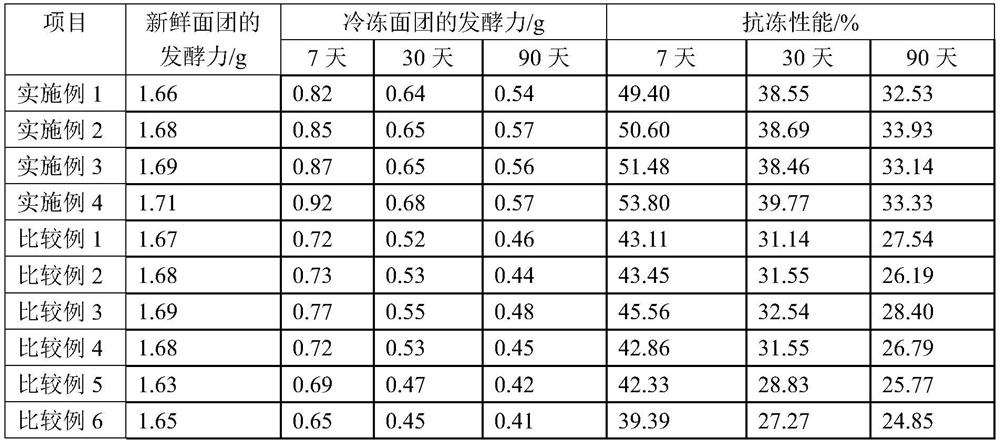

Examples

Embodiment 1

[0030] A. Prepare 0.2 parts of citrus fiber, 65 parts of high-gluten wheat flour, 2.5 parts of castor sugar, 5 parts of dry yeast, 1 part of whole milk powder, 3 parts of vegetable oil, 0.6 parts of edible refined salt, and 1.2 parts of compound frozen dough improver , 30 parts of water, spare; compound frozen dough improver, including diacetyl tartrate mono-diglyceride, trehalose, α-amylase, xylanase with a mass component ratio of 20:3.22:0.1:0.15:0.18 , Glucose oxidase.

[0031] B. At 20°C and humidity 55% RH, mix citrus fiber, high-gluten wheat flour, castor sugar, dry yeast, whole milk powder, and compound frozen dough improver, and stir at 140 rpm for 1 min;

[0032] C. Add water, stir at 140 rpm for 2 min; then stir at 280 rpm for 2 min;

[0033] D. Add vegetable oil and edible refined salt, stir at 140 rpm for 2 minutes; then stir at 280 rpm for 4 minutes, and control the dough temperature at 22±2°C;

[0034] E. Cover the above-mentioned dough with film and proof for ...

Embodiment 2

[0037] A. Prepare 0.8 parts of citrus fiber, 55 parts of high-gluten wheat flour, 3 parts of castor sugar, 3 parts of fresh yeast, 3 parts of whole milk powder, 2.2 parts of vegetable oil, 0.8 parts of refined edible salt, and 0.9 parts of compound frozen dough improver , 32 parts of water, spare; compound frozen dough improver, including diacetyl tartrate mono-diglyceride, trehalose, α-amylase, xylanase with a mass component ratio of 20:1:0.1:0.3:0.18 , Glucose oxidase.

[0038] B. Mix citrus fiber powder, high-gluten wheat flour, castor sugar, fresh yeast, whole milk powder, and compound frozen dough improver at 25°C and humidity 55% RH, and stir at 120 rpm for 2 minutes;

[0039] C. Add water, stir at 120 rpm for 1 min; then stir at 280 rpm for 1 min;

[0040] D. Add vegetable oil and edible refined salt, stir at 120 rpm for 2 minutes; then stir at 280 rpm for 3 minutes, and control the dough temperature at 22±2°C;

[0041] E. Cover the above-mentioned dough with a film a...

Embodiment 3

[0044] A. Prepare 0.5 parts of citrus fiber, 60 parts of high-gluten wheat flour, 2.8 parts of castor sugar, 4 parts of dry yeast, 2 parts of whole milk powder, 2.5 parts of vegetable oil, 0.7 parts of edible refined salt, and 1 part of compound frozen dough improver , 31 parts of water, spare; compound frozen dough improver, including diacetyl tartrate mono-diglyceride, trehalose, α-amylase, xylanase with a mass component ratio of 20:2:0.1:0.2:0.18 , Glucose oxidase.

[0045] B. Mix citrus fiber powder, high-gluten wheat flour, castor sugar, dry yeast, whole milk powder, and compound frozen dough improver at 22°C and humidity 55% RH, and stir at 120 rpm for 2 minutes;

[0046] C. Add water, stir at 120 rpm for 2 minutes; then stir at 290 rpm for 1 min;

[0047] D. Add vegetable oil and edible refined salt, stir at 140 rpm for 1 min; then stir at 290 rpm for 3 min, and control the dough temperature at 22±2°C;

[0048] E. Cover the above-mentioned dough with a film and proof fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com