A kind of process of recovering sericite from gold dressing tailings

A technology for sericite and magnetic separation of tailings, which is applied in the direction of mechanical material recovery, recycling technology, solid separation, etc., can solve the problems such as the inability to guarantee the purity grade of sericite, the inability to guarantee the content, and the reduction of recovery efficiency, so as to reduce the cost and The effect of discharge of industrial polluting waste liquid, improvement of fineness and purity, and improvement of recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

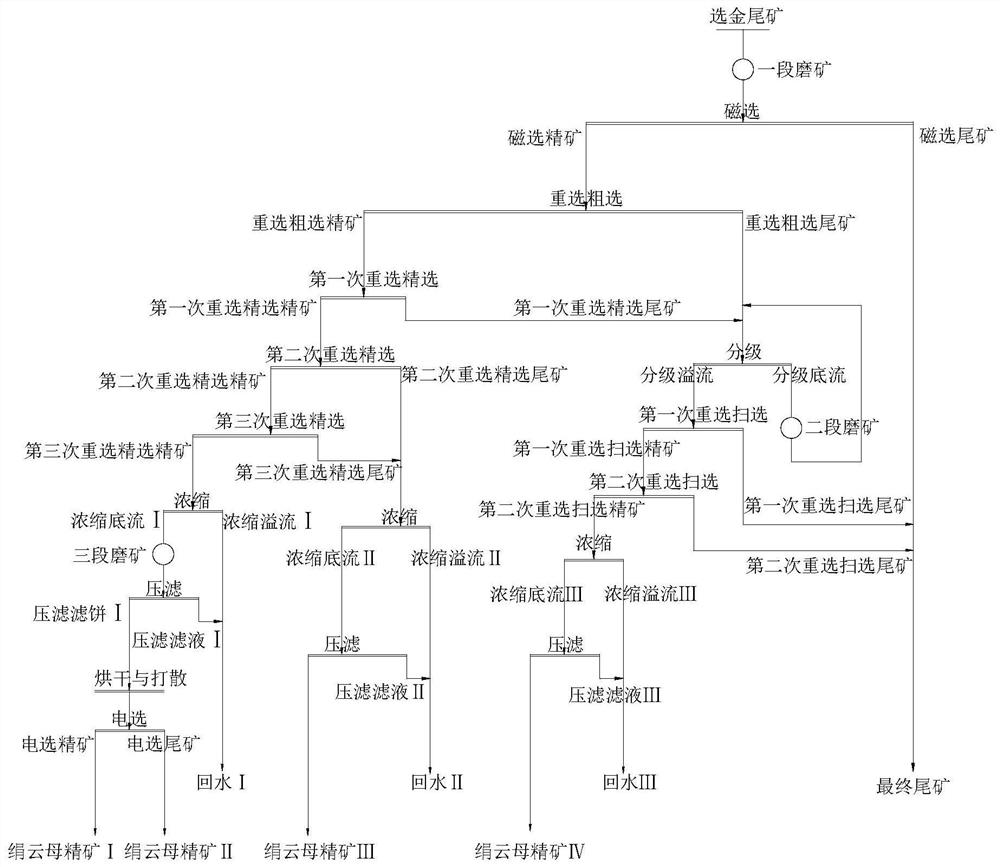

[0020] A kind of technology that gold dressing tailings reclaims sericite, comprises the following steps:

[0021] (1) Magnetic separation: the Al 2 o 3 The gold dressing tailings with a content of 11.35% are subjected to one-stage grinding, and the grinding fineness of the one-stage grinding is -200 mesh, and the content ratio is 80%. The products after grinding are subjected to magnetic separation, and the magnetic field strength of the magnetic separation is 0.35 T, obtain magnetic separation concentrate and magnetic separation tailings;

[0022] (2) Gravity separation and roughing: the magnetic separation concentrate is subjected to gravity separation to obtain the gravity separation concentrate and gravity separation tailings;

[0023] (3) Re-election and concentration: carry out the first re-selection and concentration of the re-election rough concentrate to obtain the first re-selection concentrate and the first re-selection tailings, and then the first re-election G...

Embodiment 2

[0028] A kind of technology that gold dressing tailings reclaims sericite, comprises the following steps:

[0029] (1) Magnetic separation: the Al 2 o 3 The gold dressing tailings with a content of 11.35% are subjected to one-stage grinding, and the grinding fineness of the one-stage grinding is -200 mesh, and the content ratio is 85%. The products after grinding are subjected to magnetic separation, and the magnetic field strength of the magnetic separation is 0.40 T, obtain magnetic separation concentrate and magnetic separation tailings;

[0030] (2) Gravity separation and roughing: the magnetic separation concentrate is subjected to gravity separation to obtain the gravity separation concentrate and gravity separation tailings;

[0031] (3) Re-election and concentration: carry out the first re-selection and concentration of the re-election rough concentrate to obtain the first re-selection concentrate and the first re-selection tailings, and then the first re-election Gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com