Electro-hydraulic hybrid drive double-head breaking and disassembling robot and breaking and disassembling method

An electro-hydraulic hybrid and robotic technology, which is applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of difficult demolition of refractory bricks in large rotary kilns, limited application range of demolition, and manufacturing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

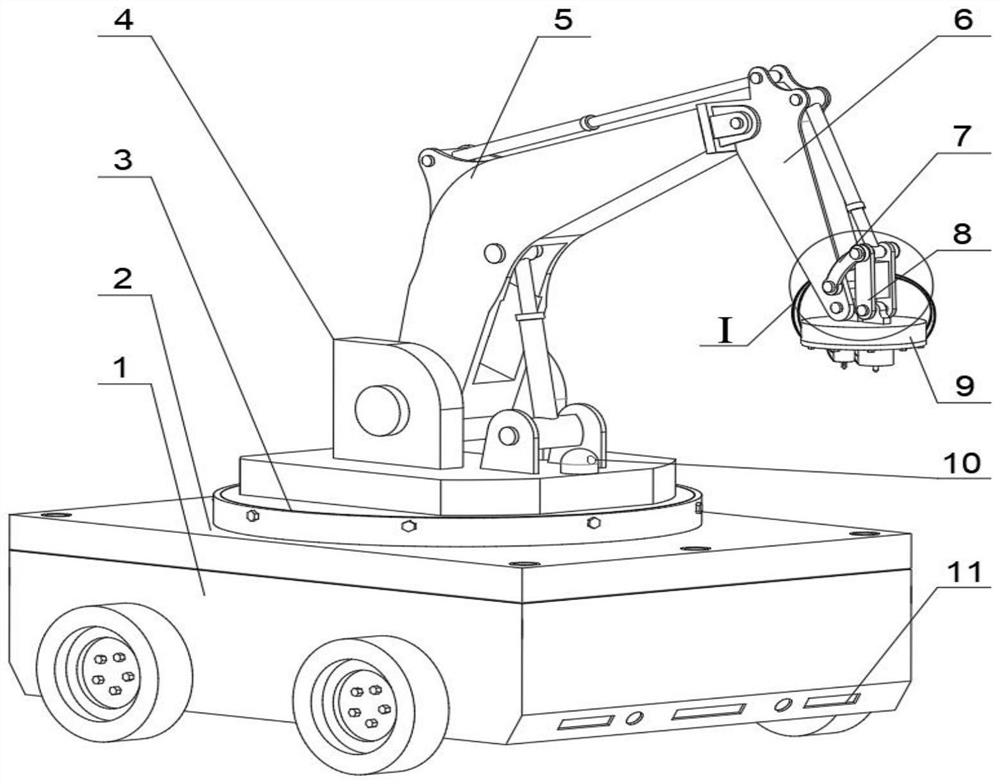

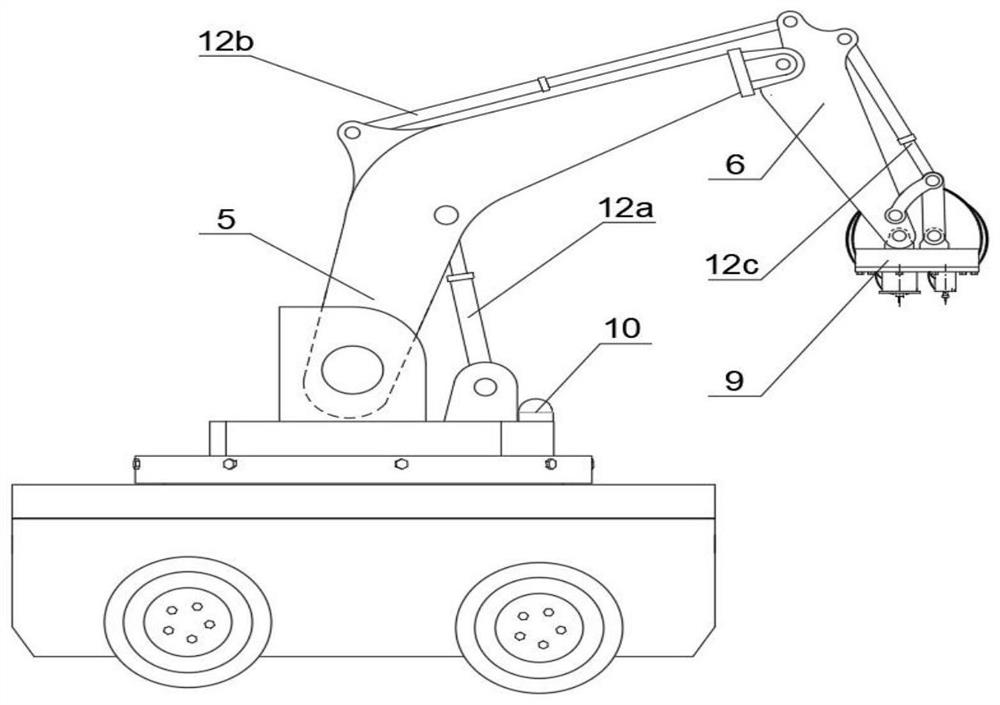

[0044] The invention provides an electro-hydraulic hybrid driven double-head rescue robot and a rescue method. The invention is suitable for the rescue of residual refractory bricks in a rotary kiln. The robot includes a bearing reversing system, a rescue system and a control system.

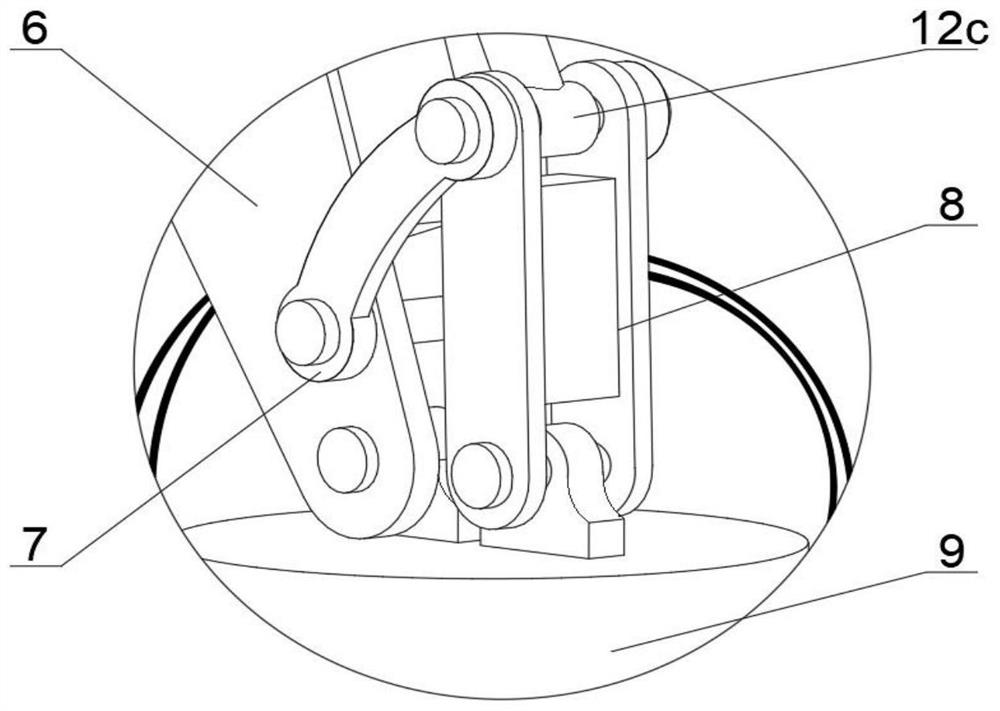

[0045] The bearing reversing system includes a car body 1, a cover plate 2, a retaining ring 3, a workbench 4, a first hydraulic arm 5, a second hydraulic arm 6, a first hydraulic cylinder 12a, a second hydraulic cylinder 12b, and a third hydraulic cylinder 12c , Integration box 9, slewing bearing 13, reversing gear 39 and reversing motor 40. The car body 1 and the cover plate 2 are fixedly connected by a number of countersunk bolts. The car body 1 has the function of moving and locking, so that the robot can move to the designated working position and lock it, so that the robot can change the working position in the direction of the rotary kiln axis. At the same time, the location of the demoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com