A method for producing methane by anaerobic fermentation of straw

A technology for anaerobic fermentation and production of methane, which is applied in the direction of fermentation, waste fuel, etc. It can solve the problems affecting the success of anaerobic fermentation process, the reduction of biogas yield, and the deterioration of water absorption, so as to achieve small loss, reduce pollution, and use low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

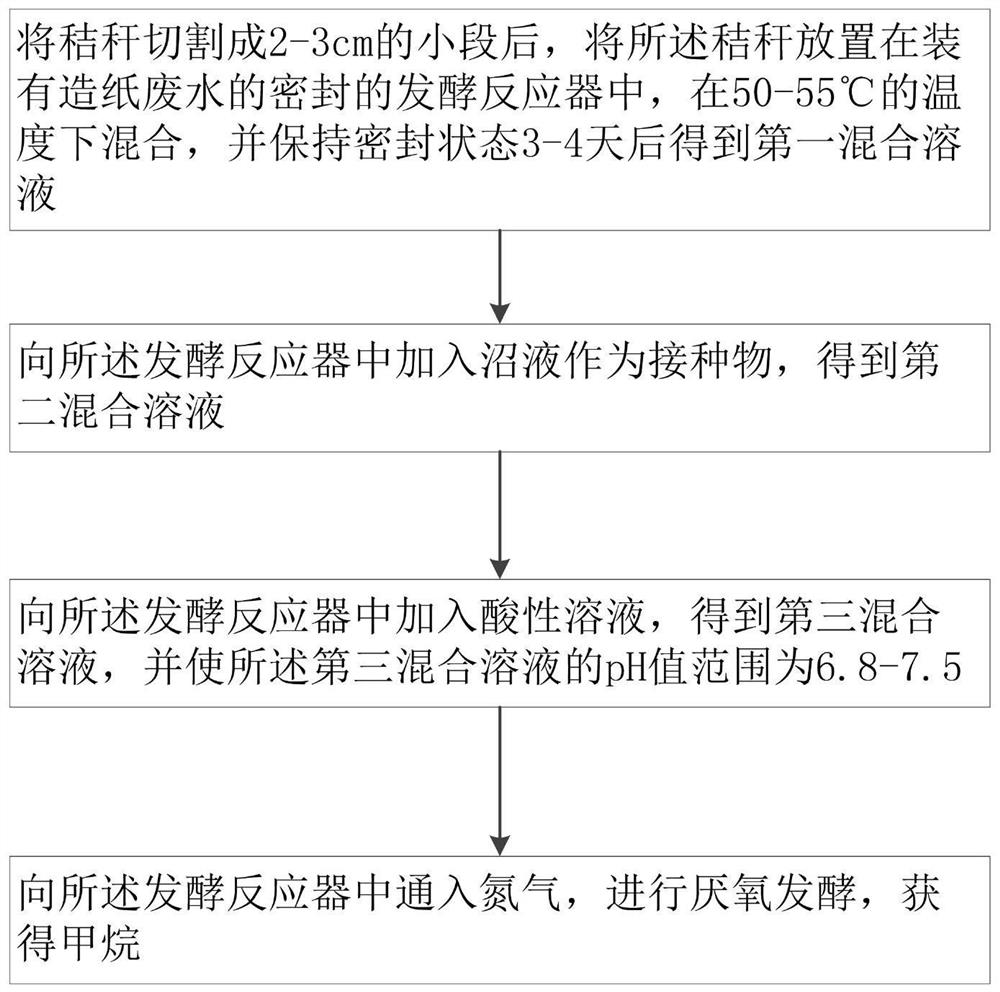

Method used

Image

Examples

Embodiment 1

[0048] A method for producing methane by anaerobic fermentation of stalks provided in this embodiment comprises the following steps:

[0049] Step 1, after cutting the straw into 2cm segments, and according to the ratio that every 100g of the straw requires 2000ml of the papermaking wastewater, the straw is placed in a sealed transparent fermentation reactor filled with papermaking wastewater, and the Mix at a temperature of ℃, keep the sealed state for 3 days to obtain the first mixed solution; shake the fermentation reactor twice a day, each time for 4 minutes, so that the papermaking wastewater can fully treat the straw;

[0050] Step 2, adding biogas slurry into the fermentation reactor as an inoculum to obtain a second mixed solution, and ensuring that the total solid content of the second mixed solution is in the range of 6%;

[0051] Step 3, adding an acidic solution into the fermentation reactor to obtain a third mixed solution, and making the pH range of the third mix...

Embodiment 2

[0055] A method for producing methane by anaerobic fermentation of stalks provided in this embodiment comprises the following steps:

[0056] Step 1: After cutting the stalks into small sections of 3 cm, and according to the ratio that 2600 ml of the papermaking wastewater is required for every 130 g of the stalks, the stalks are placed in a sealed transparent fermentation reactor filled with papermaking wastewater, and the Mix at a temperature of ℃, and keep the sealed state for 3 days to obtain the first mixed solution; and shake the fermentation reactor 3 times a day, each time for 5 minutes, so that the papermaking wastewater can fully treat the straw;

[0057] Step 2, adding biogas slurry into the fermentation reactor as an inoculum to obtain a second mixed solution, and ensuring that the total solid content of the second mixed solution is in the range of 7%;

[0058] Step 3, adding an acidic solution into the fermentation reactor to obtain a third mixed solution, and mak...

Embodiment 3

[0062] A method for producing methane by anaerobic fermentation of stalks provided in this embodiment comprises the following steps:

[0063] Step 1, after cutting the straw into small sections of 3 cm, and according to the ratio that every 150 g of the straw needs 3000 ml of the papermaking wastewater, the straw is placed in a sealed transparent fermentation reactor filled with papermaking wastewater, and the Mix at a temperature of ℃, and keep the sealed state for 4 days to obtain the first mixed solution; and shake the fermentation reactor 3 times a day, each time lasting for 6 minutes, so that the papermaking wastewater can fully treat the straw;

[0064] Step 2, adding biogas slurry into the fermentation reactor as an inoculum to obtain a second mixed solution, and ensuring that the total solid content of the second mixed solution is in the range of 8%;

[0065] Step 3, adding an acidic solution into the fermentation reactor to obtain a third mixed solution, and making th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com