Real-time disinfectant manufacturing structure

A disinfectant and electrode technology, applied in the field of real-time disinfectant manufacturing structures, can solve problems such as the inability to truly meet stable real-time preparation, and achieve the effects of long battery life, high ion diffusion rate, and high electrode efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

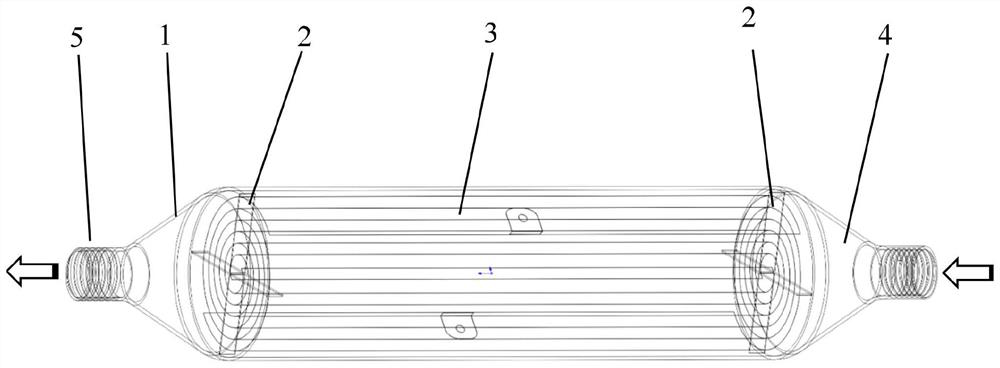

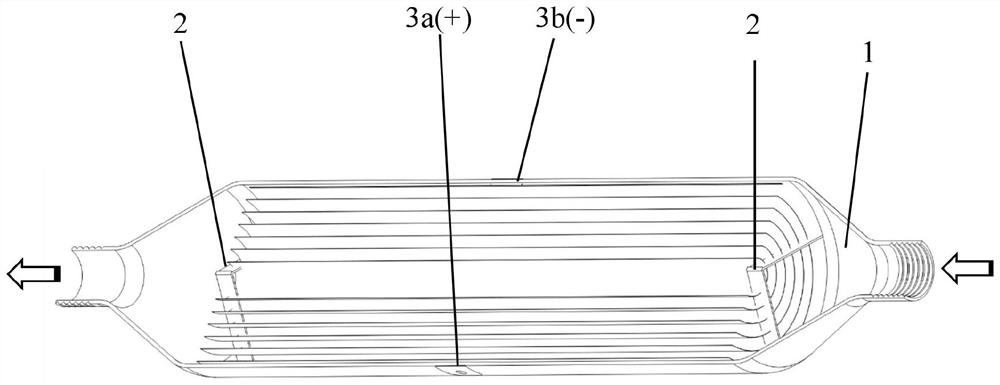

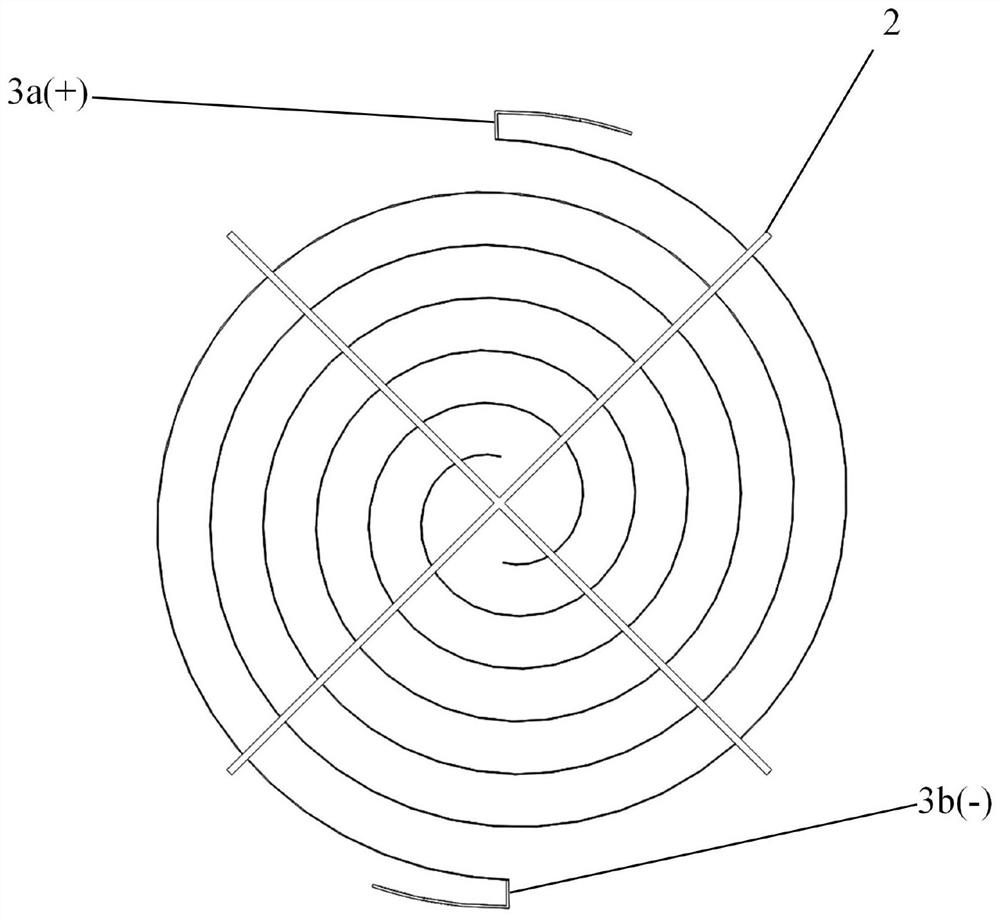

[0055] Embodiment one: if Figure 1 to Figure 3 As shown, it is a structural schematic diagram of an electrolytic chamber of a double-helix sheet-like structure electrode of the present invention, including the following main features:

[0056] The electrodes 3 are equidistant double helical sheet structures, one pole is connected to the positive pole of the DC power supply, and the other pole is connected to the negative pole of the DC power supply. Scattered and discharged, the electrode 3 is connected to the positive and negative poles of the DC power supply with wires, where 3a means to connect to the positive pole, and 3b means to connect to the negative pole;

[0057] The electrolysis reaction occurs between the double helix sheets, and the hydrogen and sodium hypochlorite generated by the electrolysis;

[0058] Depending on the scale of implementation, the distance between the double-screw electrodes should be between 2 and 20mm. It is advisable to avoid short circuit ...

Embodiment 2

[0066] Embodiment two: if Figure 4 Shown is a schematic diagram of the shell structure of the electrolytic chamber of the ring or tubular electrode of the present invention, including the following main features:

[0067] Ring or tubular structure electrodes surround the straight wire electrode, the ring or tubular structure is connected to the positive pole of the DC power supply, and the straight wire electrode is connected to the negative pole of the DC power supply, and the sodium chloride or potassium chloride solution flows from one end to the other end through the electrode , and then quickly dispersed and discharged through nozzles or nozzles;

[0068] The electrolysis reaction takes place between the electrodes, the straight wire electrode produces hydrogen, the ring or tubular structure electrode obtains electrons from chloride ions or water molecules to produce chlorine gas and a small amount of oxygen, chlorine gas reacts with water to generate and hypochlorous ac...

Embodiment 3

[0075] Embodiment three: as Figure 5 As shown, it is a schematic diagram of the structure of the electrolytic chamber shell of the mesh electrode of the present invention, including the following main features:

[0076] Mesh structure electrodes are arranged staggeredly according to the cathode and anode in the direction of liquid flow, and are respectively connected to the positive and negative electrodes of the DC power supply. The sodium chloride or potassium chloride solution flows from one end to the other end through the electrode, and then is atomized through the nozzle or nozzle. Quickly disperse and discharge;

[0077]The cathode mesh and the anode mesh of the mesh electrode can be the same or different, and the mesh size and density of each mesh electrode can be the same or different;

[0078] The electrolysis reaction takes place between the electrode nets, the cathode produces hydrogen, the anode obtains electrons from chlorine ions or water molecules to produce ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap