Automatic barrel plating production line

A production line, automatic control technology, applied in conveyor objects, conveyors, electrolysis processes, etc., can solve the problems of time-consuming and energy-consuming, low production efficiency, and no parts are set to transfer to the material basket, etc., to improve work efficiency, improve The degree of automation, the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

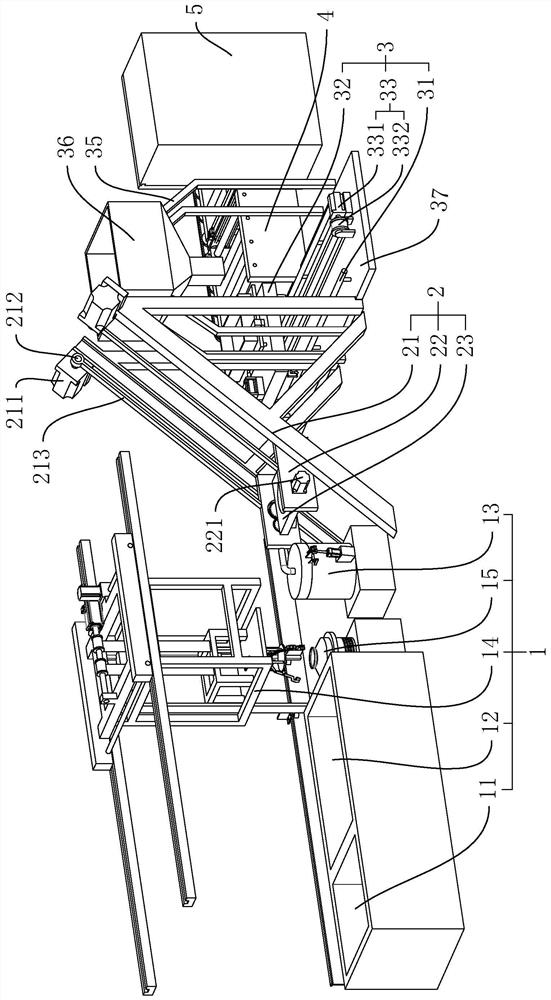

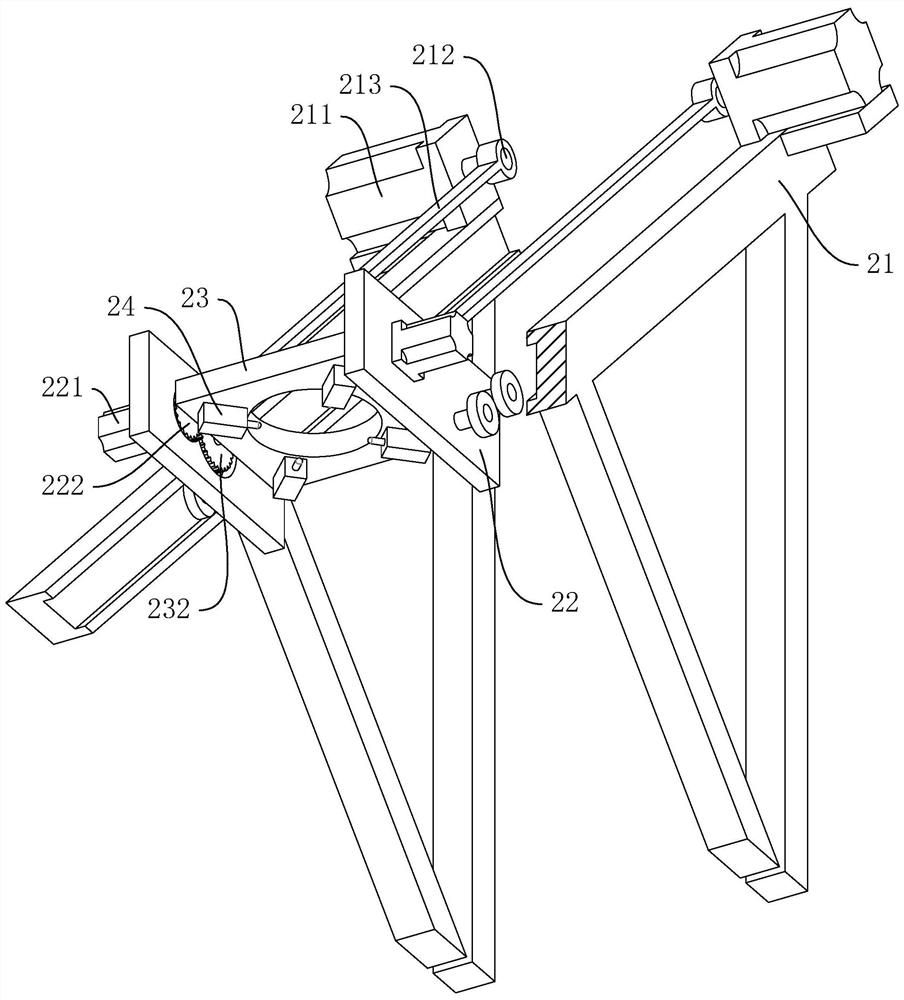

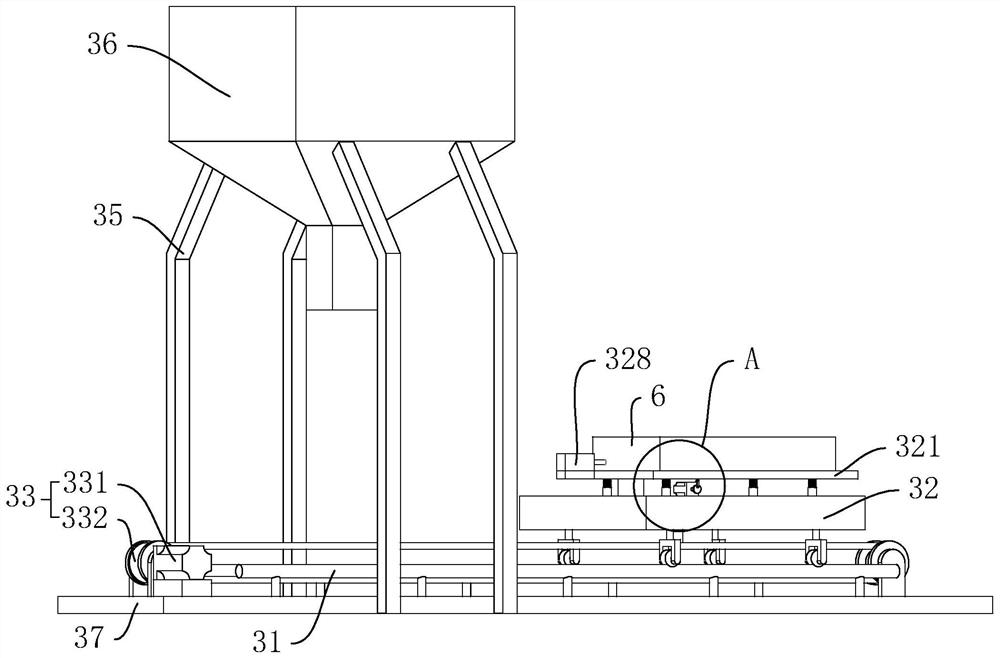

[0051] refer to figure 1 , is a kind of automatic barrel plating production line disclosed by the present invention, comprising barrel plating system 1, material transfer system, dehydrogenation system and automatic control system, barrel plating system 1, material transfer system and dehydrogenation system are all electrically connected with the automatic control system Connected, the automatic control system can control the barrel plating system 1, the material transfer system and the hydrogen removal system to perform automatic work. The barrel plating system 1 comprises an electroplating device, a cleaning device 12, a drying device 13 arranged in sequence, a drying cylinder 15 for placing parts and a mobile hanger 14 for moving the drying cylinder 15; parts can be electroplated in the electroplating device, when After the electroplating of parts is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com